Armature of rotating electric machine and method of manufacturing the same

A technology for a rotating electrical machine and an armature, which is applied to the armature of a rotating electrical machine and its manufacturing field, can solve the problems such as the reduction of the accuracy of the shaft center of the cylinder hole, the inability to fully ensure the contact area between the shaft and the shaft hole, the lamination deviation, etc., and achieve rotational balance. Excellent and smooth thinning and drawing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

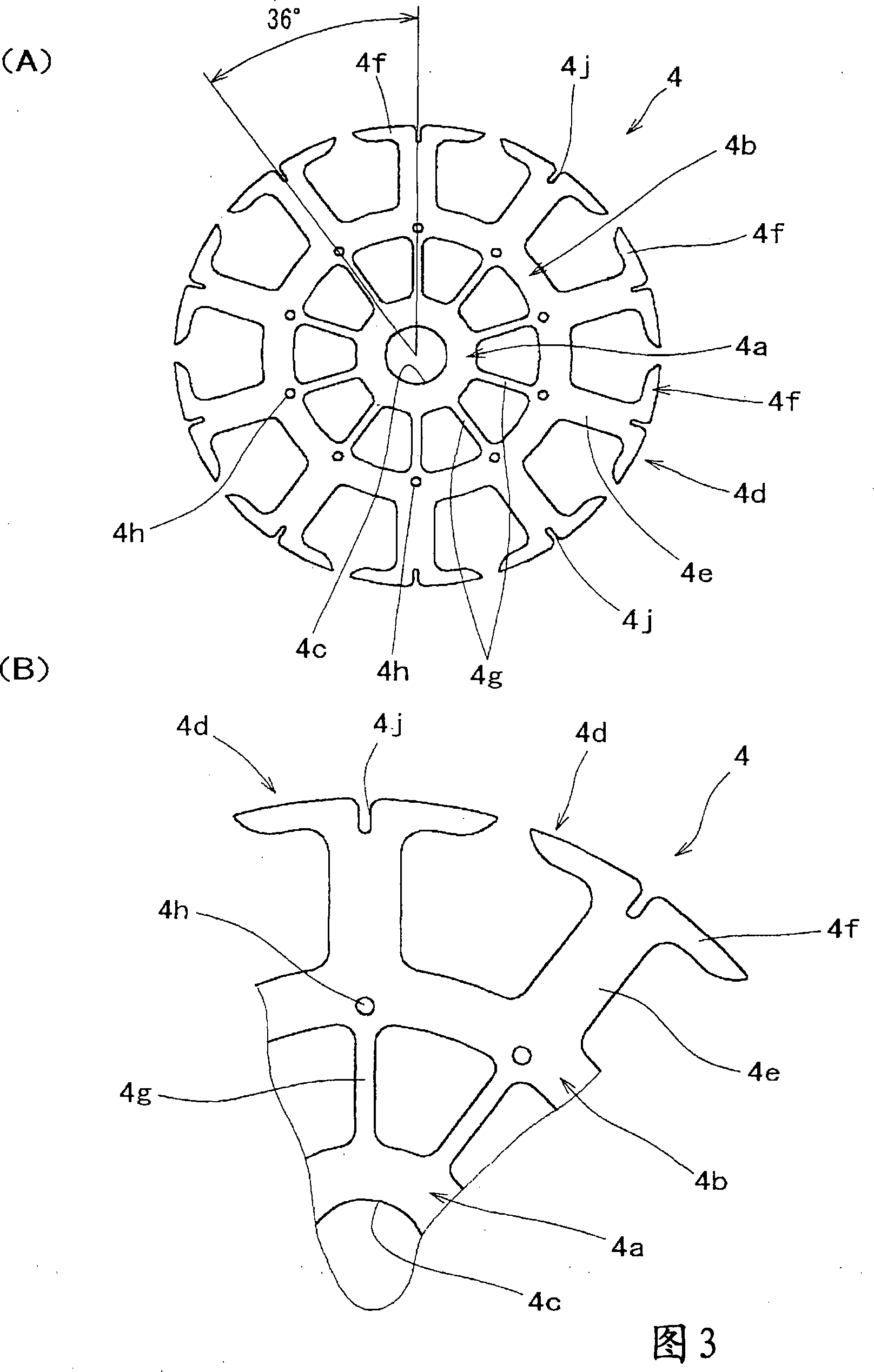

[0065] The second embodiment utilizes the main core 9 and the sub-core 10, and laminates a plurality of sub-cores 10 on both sides of the multi-piece main core 9 to form the core 8, which is the same as the previous embodiment. Part 9 has an inner diameter side ring portion 9a, an outer diameter side ring portion 9b, and 10 bridge pieces 9c connecting their circumferential rotation directions, and a sub-core member 10 has a ring portion 10a, and each core member 9,10 10 teeth 9d, 10b in the direction of circumferential rotation are formed on the outer periphery of the rim. Furthermore, in this structure, although the caulking portions 9e, 10c as an integrated mechanism for integrating the core members 9, 10 are formed on the outer diameter side of the bridge piece portion 9c, these caulking portions 9e, 10c are formed along the The middle portion of the teeth 9d, 10b adjacent in the circumferential rotation direction in the main core member outer diameter ring portion 9b and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com