Drying device

A drying device and drying technology, which is applied in the field of drying devices of machines, can solve the problems of laboriousness and easy failure of fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

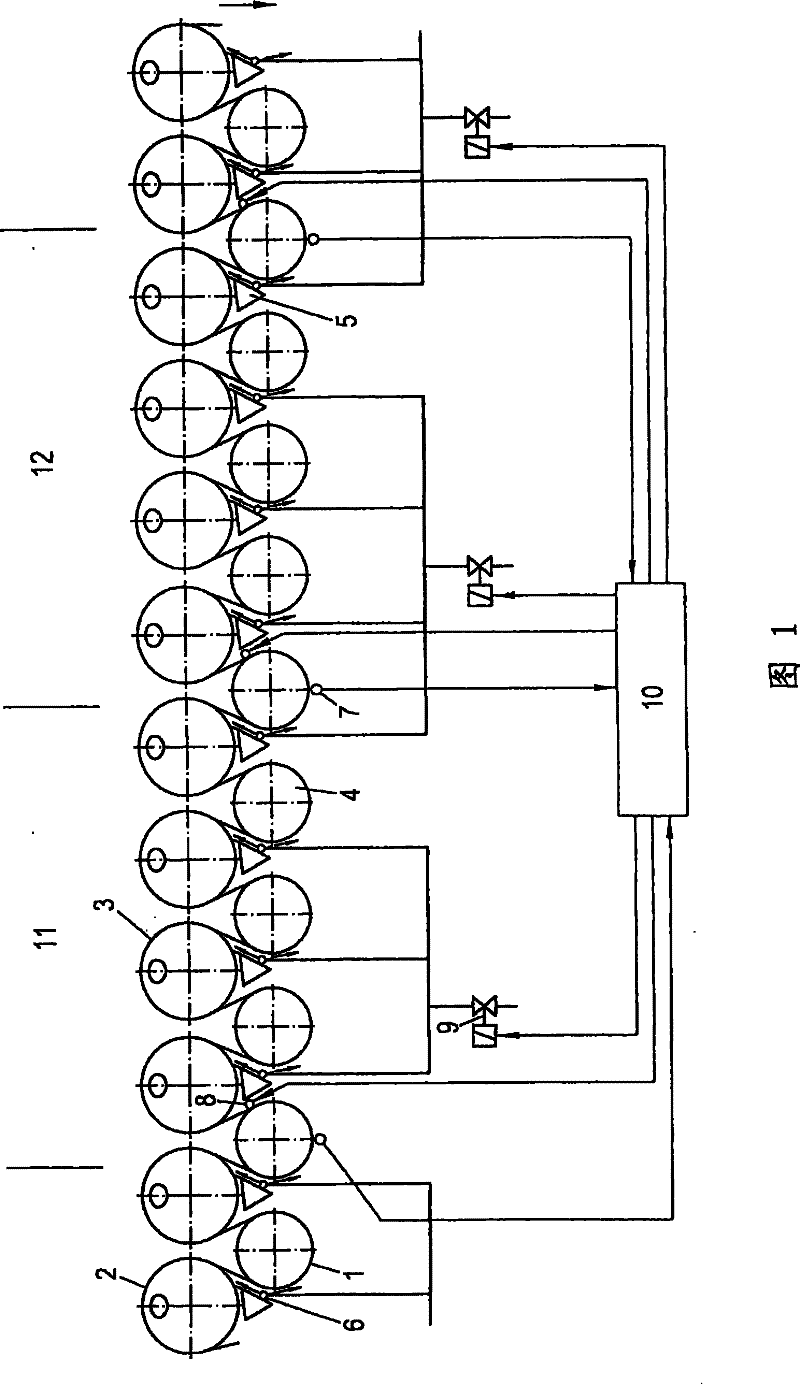

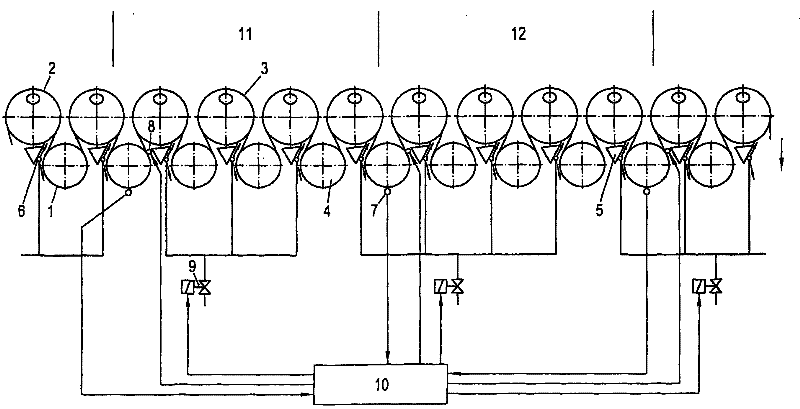

[0030] The drying device has a plurality of drying units, in which the fibrous web 1 is supported by a drying wire 2 of the respective drying unit and alternately meanders through heated drying cylinders 3 and suctioned guide rollers 4 .

[0031] The drying cylinder 3 is located in the upper row of the drying unit and is located on the lower side of the fiber web 1 , and the guide roller 4 is located in the lower row of the drying unit and is located on the upper side of the fiber web 1 . The air-permeable drying wire 2 presses the fibrous web 1 against the hot outer surface of the drying cylinder 3 and facilitates the heat transfer to the fibrous web 1 .

[0032] The drying unit comprises a plurality of transfer units 11 , 12 arranged in series, each of which has a strip sensor 7 and a separating device 8 immediately behind it at its start.

[0033] For the transfer, the narrow transfer strip of the fibrous web 1 passes through the drying device on the guide side. After a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com