Strainer

A tensioner and body technology, applied in the directions of bundling materials and parts of bundling machinery, can solve the problems of large spring elasticity, complex structure, affecting the normal use of the tensioner, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

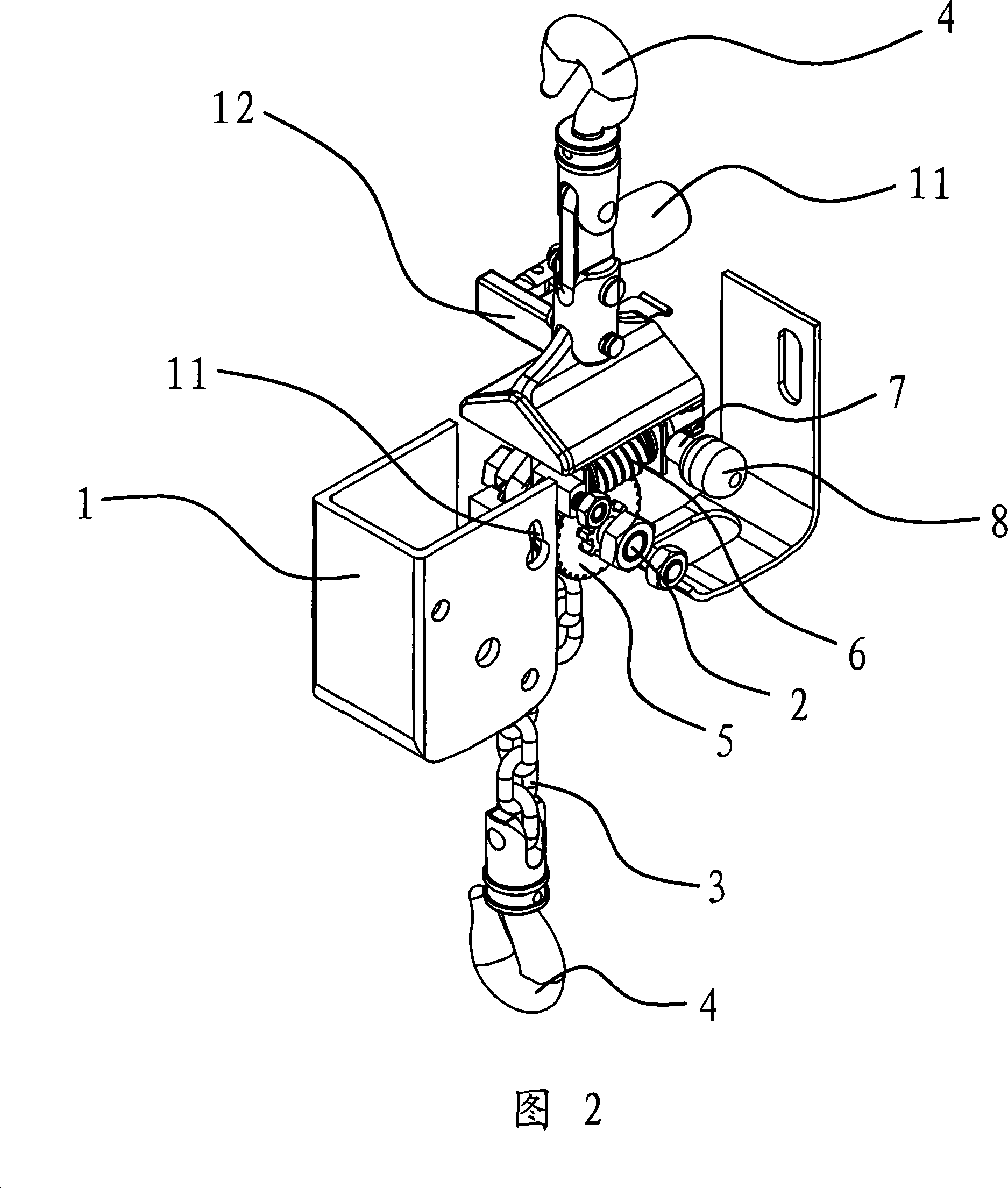

[0029] As shown in Fig. 1 and Fig. 2, the tensioner is used to bind the goods on the motor vehicle to prevent the goods from being shifted or scattered. It includes a body 1 with a cavity inside, a rotatable reel 2 is arranged in the body 1, a chain 3 is wound on the reel 2, and a hook 4 is arranged at the outer end of the chain 3 . Another hook 4 is fixedly connected to the body 1 .

[0030] The reel 2 is provided with a worm wheel 5 fixedly connected thereto, and a rotatable worm 6 is also provided in the body 1 , the inner end of the worm 6 is hinged in the body 1 , and the outer end of the worm 6 passes through the body 1 . A clutch mechanism is provided between the worm 6 and the body 1 .

[0031] As shown in FIG. 3 and FIG. 4 , the clutch mechanism includes a strip-shaped positioning hole 11 opened on the body 1 and a positioning rod 7 disposed in the body 1 . The positioning hole 11 is located at the side of the worm 6 and it is arranged along the swinging direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com