Toadpoison ligand extract as well as preparation method and application thereof

A technology of bufagenin and bufagenin, which is applied in the field of bufagenin extract and its preparation and application, and can solve the problems of high incidence, complex components, and failure to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

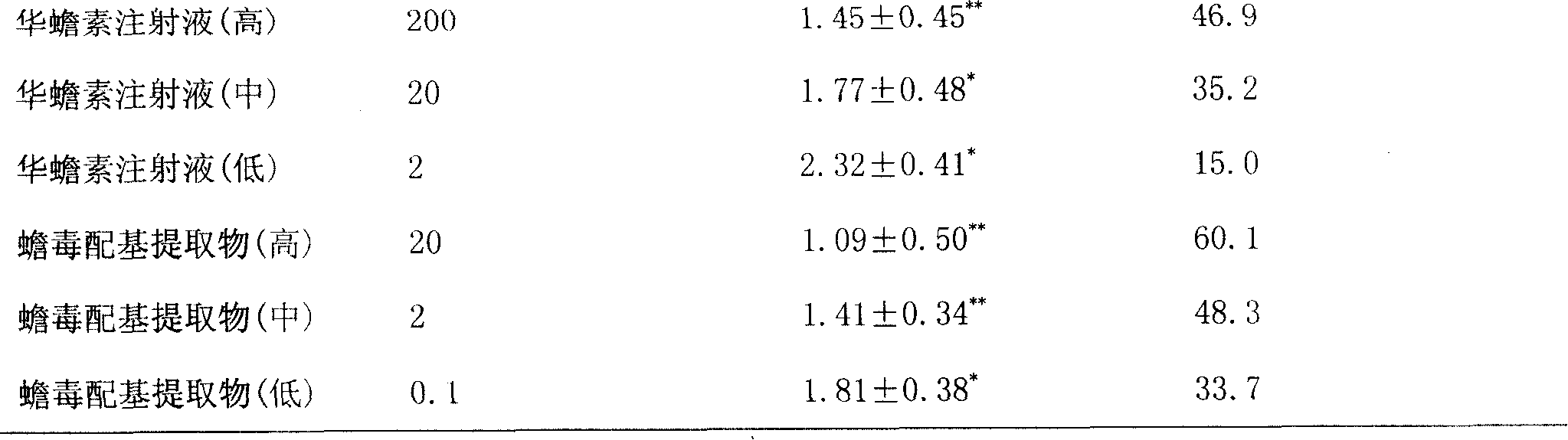

[0021] Example 1: Preparation of Bufagenin Extract

[0022] Take 10kg of dry toad skin and extract 4 times with 80% ethanol, the amount of alcohol used is 9 times, and the extraction time is 120 minutes each time, the filtrate is combined, and the filtrate is decompressed to recover the ethanol until it has no alcohol smell, and puts it on AB-8 macroporous resin Column (manufactured by Tianjin Nankai University Chemical Plant), first eluted with water, then eluted with 30% ethanol, and then eluted with 80% ethanol, collected the latter, recovered the solvent under reduced pressure, and extracted the aqueous solution with an equal amount of ethyl acetate Twice, the ethyl acetate layer was decompressed to recover the solvent, and dried to obtain 42 g of toad skin extract, the content of bufagenin was 55.3%, which contained 15.1% cinobufagin and 15.8% cinobufagenin.

Embodiment 2

[0023] Example 2: Preparation of Bufagenin Extract

[0024] Take 1 kg of dried toad venom and extract 4 times with 80% ethanol, the amount of alcohol used is 9 times, and the extraction time is 120 minutes each time, the filtrate is combined, and the filtrate is decompressed to recover ethanol until it has no alcohol smell, and put it on the AB-8 macroporous resin column (produced by the No. 2 chemical factory of Nankai University in Tianjin), elute with water first, then elute with 30% ethanol, then elute with 80% ethanol, collect the latter, recover the solvent under reduced pressure, and dry to obtain 172g of Bufagenin extract , in terms of cinobufagin, the content of bufagenin is 70.3%, which contains 20.1% cinobufagin and 17.8% lipobufagenin.

Embodiment 3

[0025] Example 3: Preparation of Bufagenin Extract

[0026] Take 2 kg of dried toad venom and extract twice with 95% ethanol, the amount of alcohol used is 10 times, and the extraction time is 90 minutes each time, the filtrate is combined, and the filtrate is decompressed to recover ethanol until it has no alcohol smell, and puts it on AB-8 (Tianjin Nankai University Chemical plant production) macroporous resin column, first eluted with water, then eluted with 40% ethanol, then eluted with 95% ethanol, collected the latter, reclaimed the solvent under reduced pressure, dried to obtain 332g of bufagenin extract, Based on cinobufagin, the content of bufogenin is 85.6%, which contains 21.4% cinobufagin and 20.3% lipobufagenin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com