Fly-shuttle loom harness frame position limiter

A technology of limiting device and heald frame, which is applied in textile, heald, textile and papermaking, etc., can solve the problems of inability to reduce the distance between front and rear healds, unreasonable weaving process, increase in distance, etc. Reduce primary friction, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

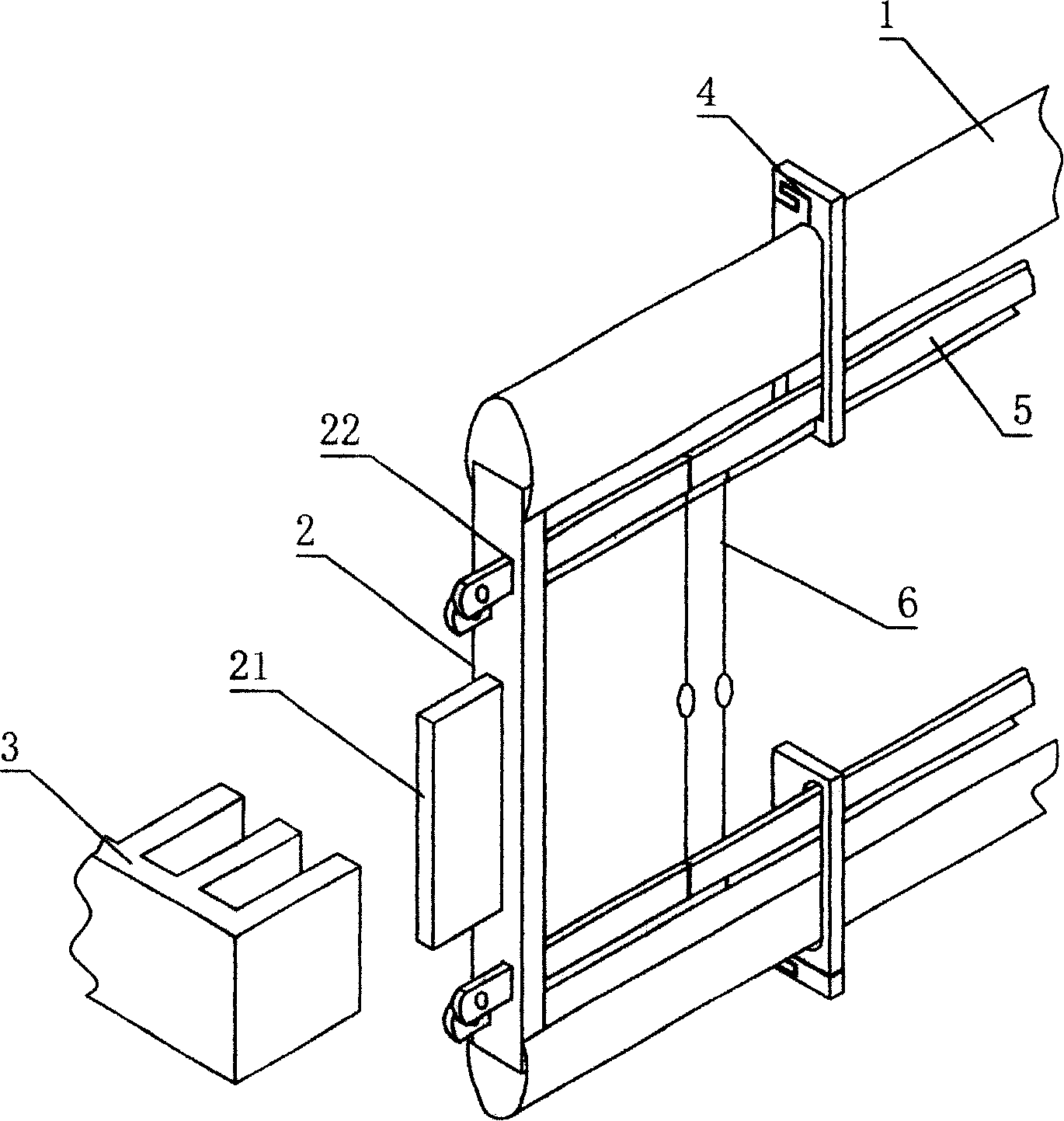

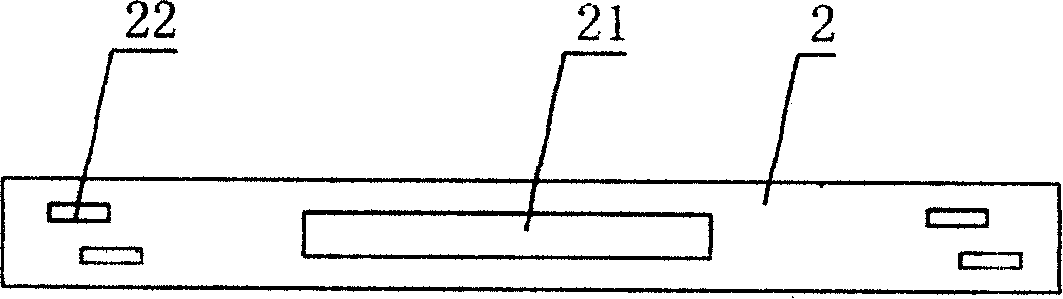

[0021] Such as figure 1 , figure 2 with image 3 As shown, the heald frame limiting device of the shuttle loom includes several rows of heald frames 1 arranged on the loom connected with the heald pulley and the heald rod, which can be two rows of heald frames for weaving plain weave, or can be used for weaving twill Three-column heald frame when weaving, etc. Both ends of the heald frame 1 are respectively provided with a heald head 2, and the heald head 2 is provided with upper and lower rows of perforations 22 for the heald rod 5 with the heddle 6 to pass through the positioning, and the heald rod 5 passes through The heald clamp 4 is fixed on the heald frame 1, and a slider 21 is provided on the heald head 2, and a limit block 3 is respectively provided at both ends of the heald frame 1 on the loom, and a slider 21 is arranged on the limit block 3. Correspondingly, the lifting track that can control the sliding of the slider 21, the sliders 21 respectively provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com