Stacking electronic component and its clamping component

A technology for electronic components and clamping components, which is applied in the field of stacked electronic components and their clamping components, can solve problems such as weakening the strength of solder 13, failure to connect and fix the energy storage unit 10, and rupture of the energy storage unit, so as to achieve protection from damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and that the descriptions and figures therein are used for illustration in nature rather than limiting the present invention.

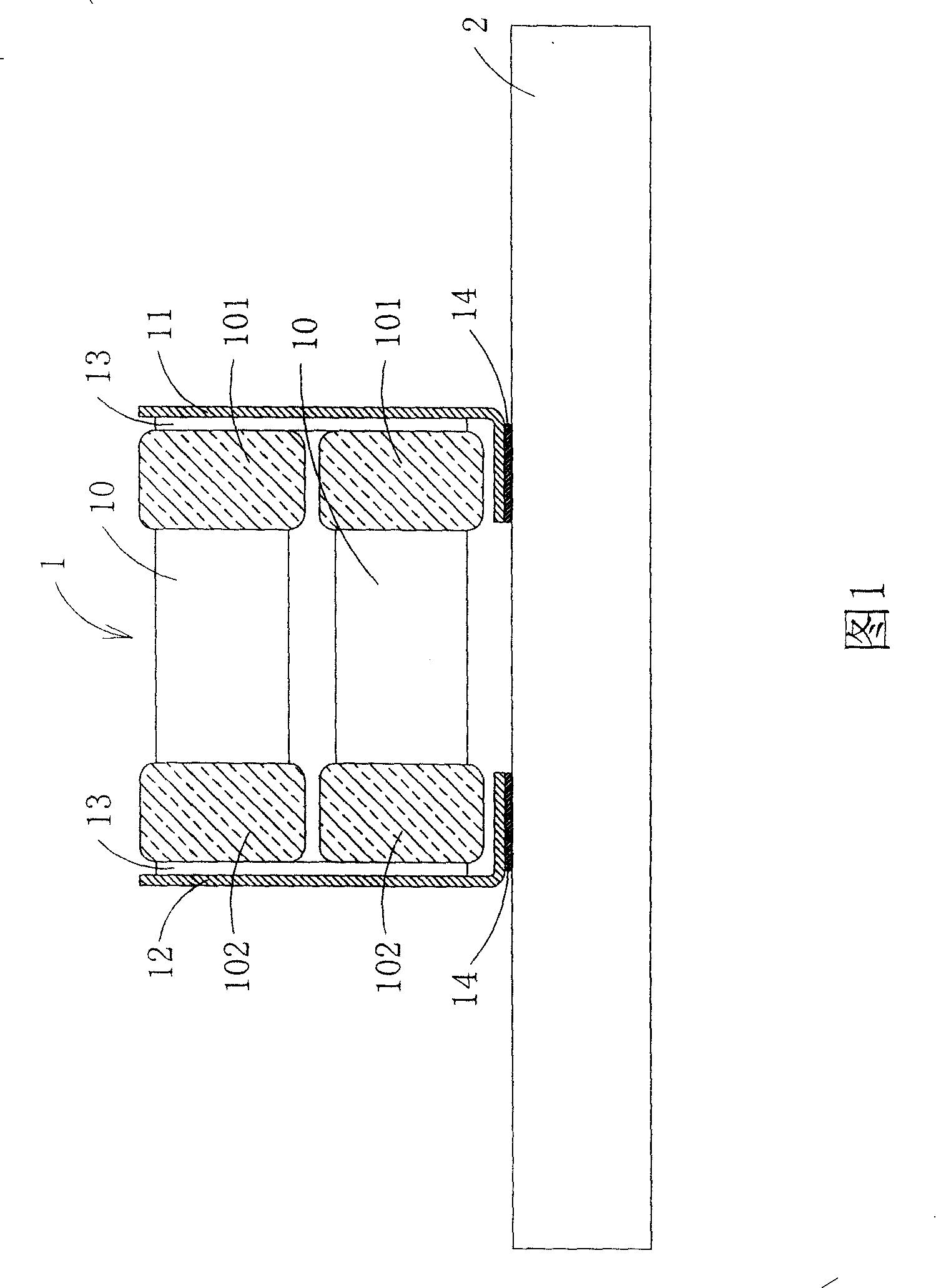

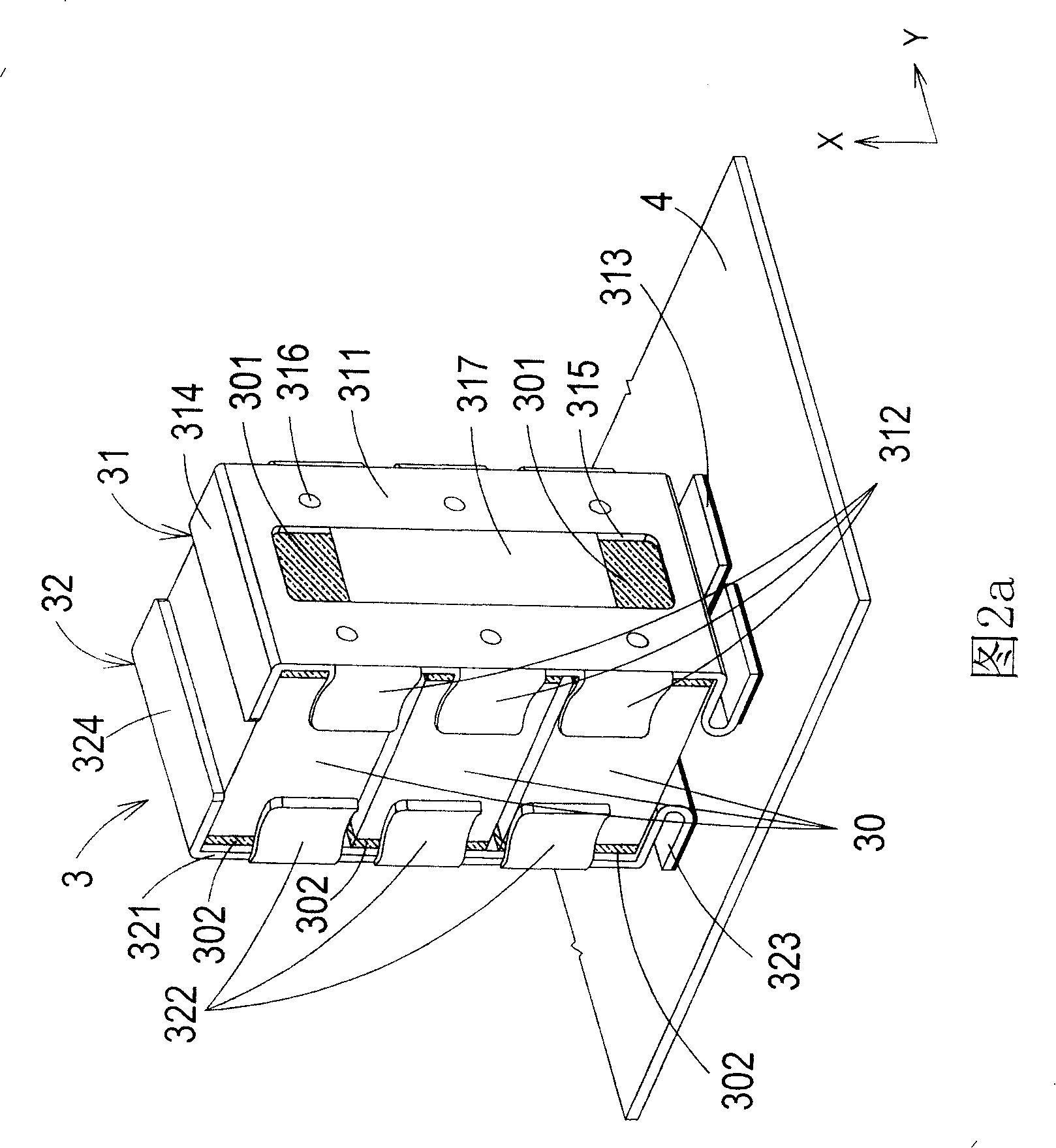

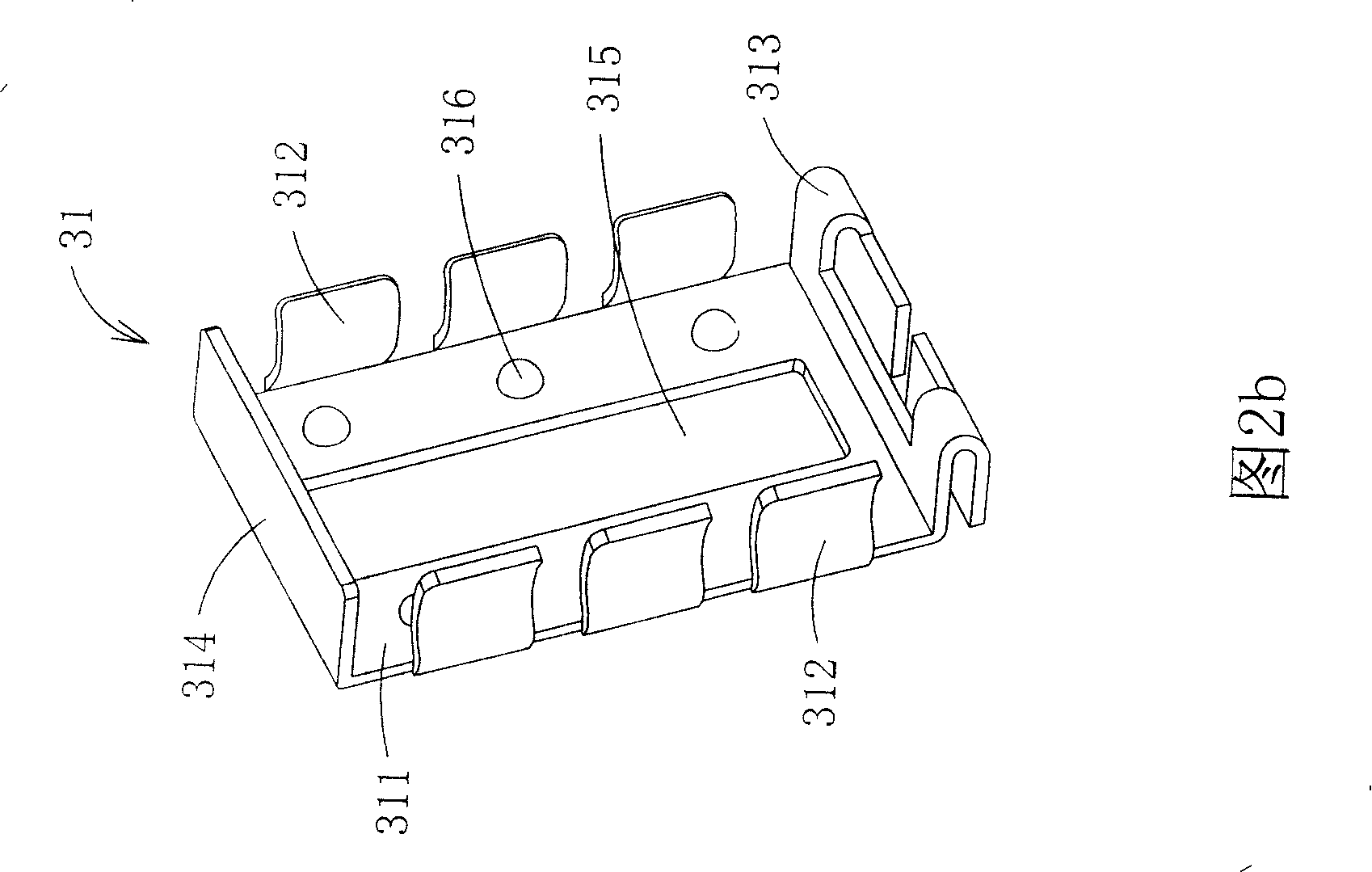

[0044] Please refer to FIG. 2( a ), which is a schematic structural diagram of a stacked electronic component according to a first preferred embodiment of the present invention. As shown in the figure, in this embodiment, the stacked electronic component 3 can be composed of three energy storage units 30, which are mainly used to store electric energy, and the two opposite sides of each energy storage unit 30 are respectively provided with a first electrode 301 and a The second electrode 302, wherein, the stacked electronic com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com