Corrosion-resistant over-voltage protection electric-heating water drainer

A technology of overpressure protection and drainer, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of drainer corrosion, anti-corrosion layer damage, difficult implementation, etc., and achieve cost saving and long service life Improve the effect of easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

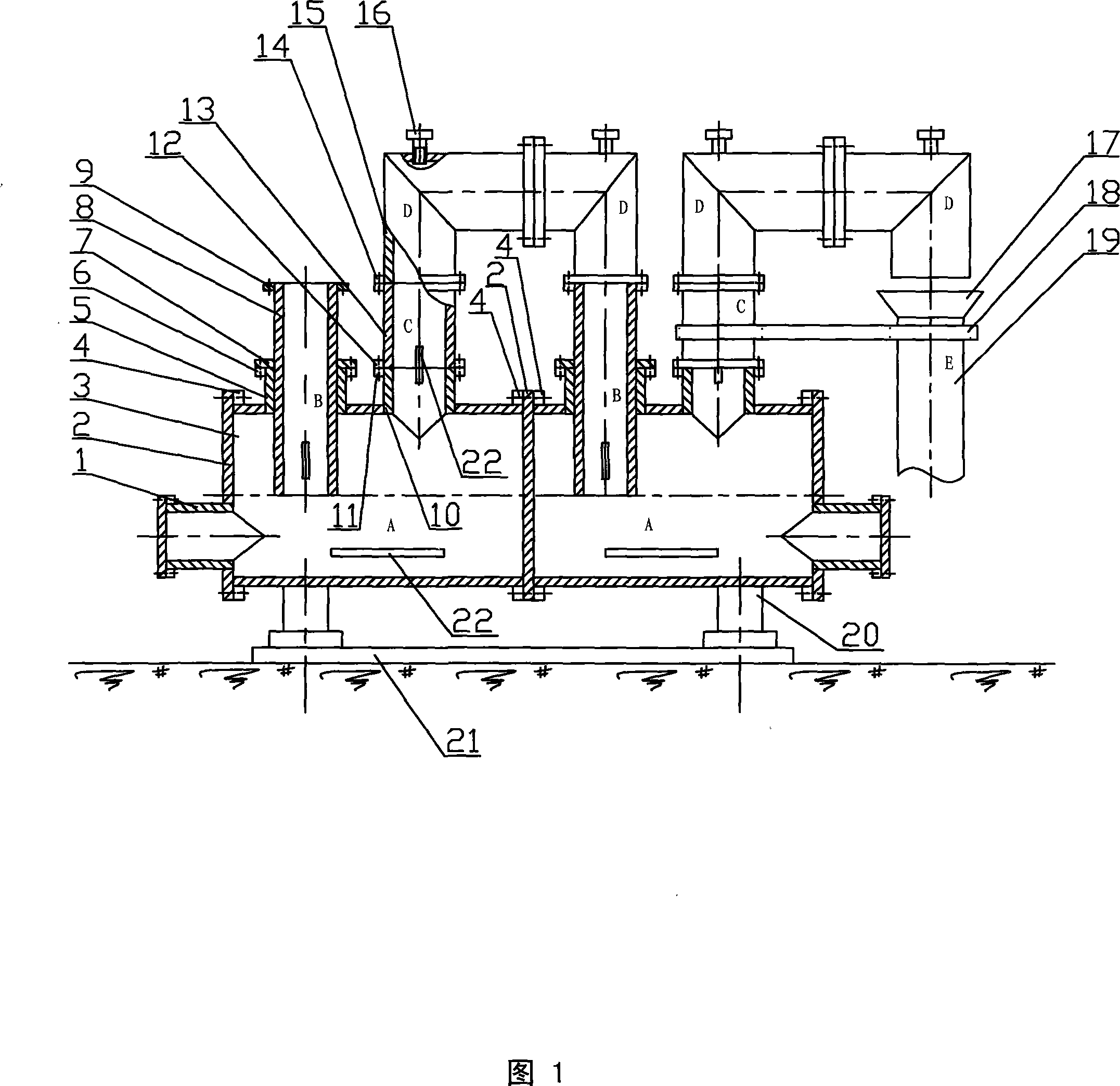

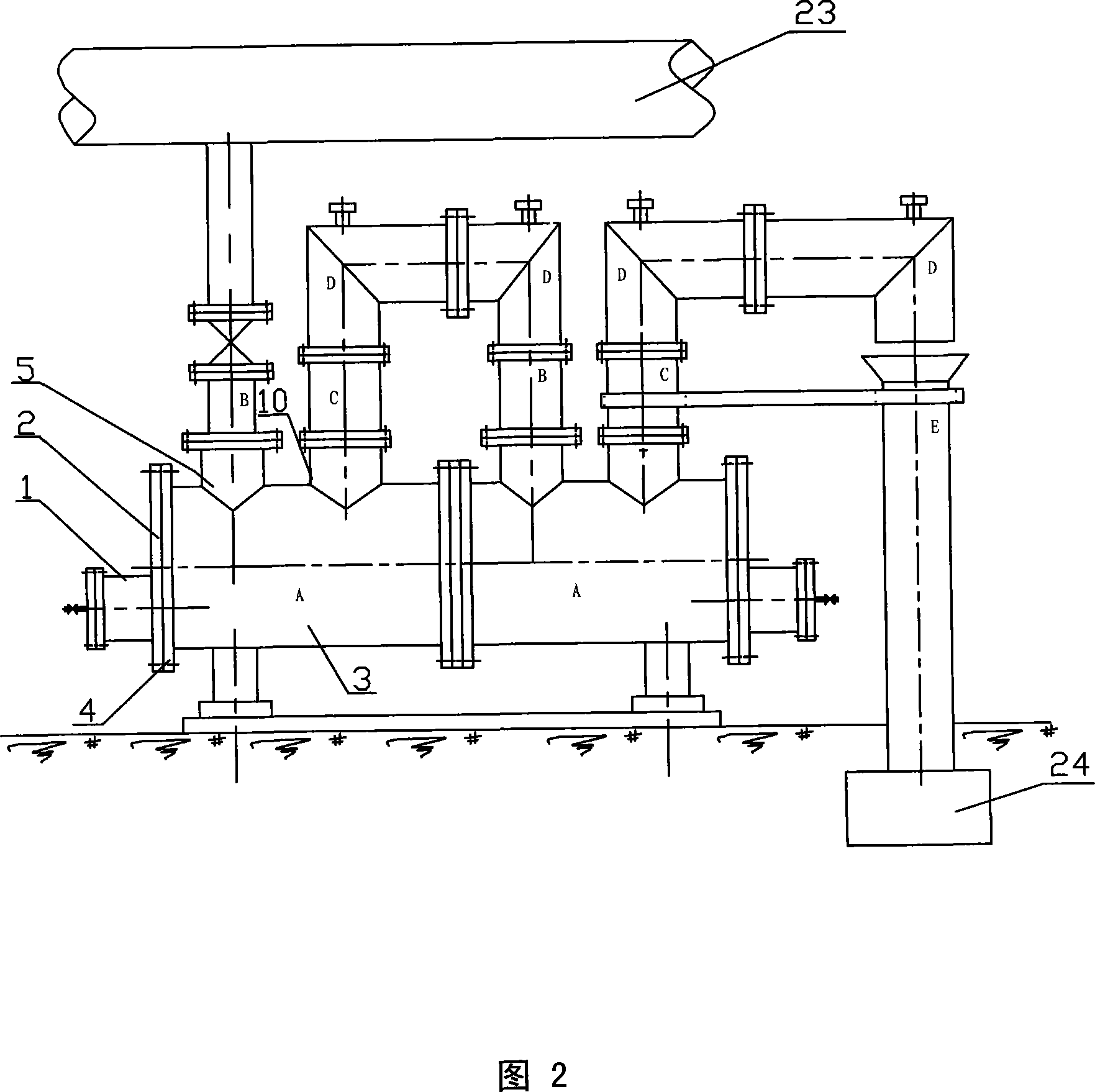

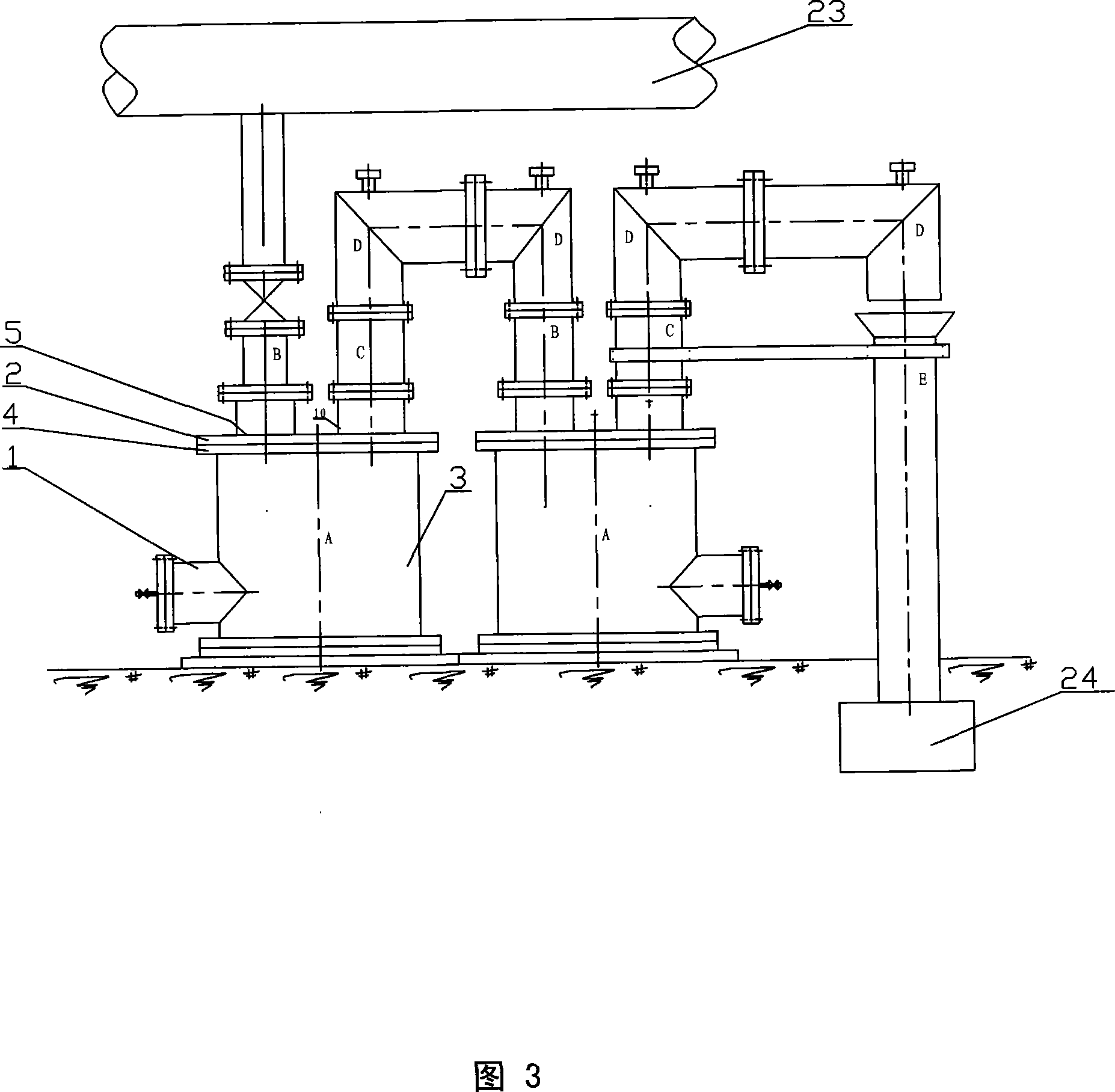

[0022] As shown in Figure 1, a corrosion-resistant overvoltage protection electric heating drain includes a body system A, an inlet pipe system B, an outlet pipe system C, a connecting pipe system D, and a downpipe system E. Flanges are used between each system and components Assembled together in a connected manner. Before assembly, the inner walls of each system and the parts in contact with sewage and gas in the drainer are treated with chemical anti-corrosion by lining or paint, or after chemical anti-corrosion treatment, an electrochemical anti-corrosion device 22 is installed on the inner wall to prevent electrochemical anti-corrosion. The device 22 can adopt a sacrificial anode or an external current facility; an electric heating device is installed on the outside of the drainer, and an electric heating element is installed on the inner cavity of the drainer system.

[0023] The body system A is located at the lower part of the drain device, including body 3, body flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com