Method for manufacturing information display panel

一种信息显示、制造方法的技术,应用在非线性光学、仪器、光学等方向,能够解决不能进行填充、面板基板距离不能固定、飞出等问题,达到间隔均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

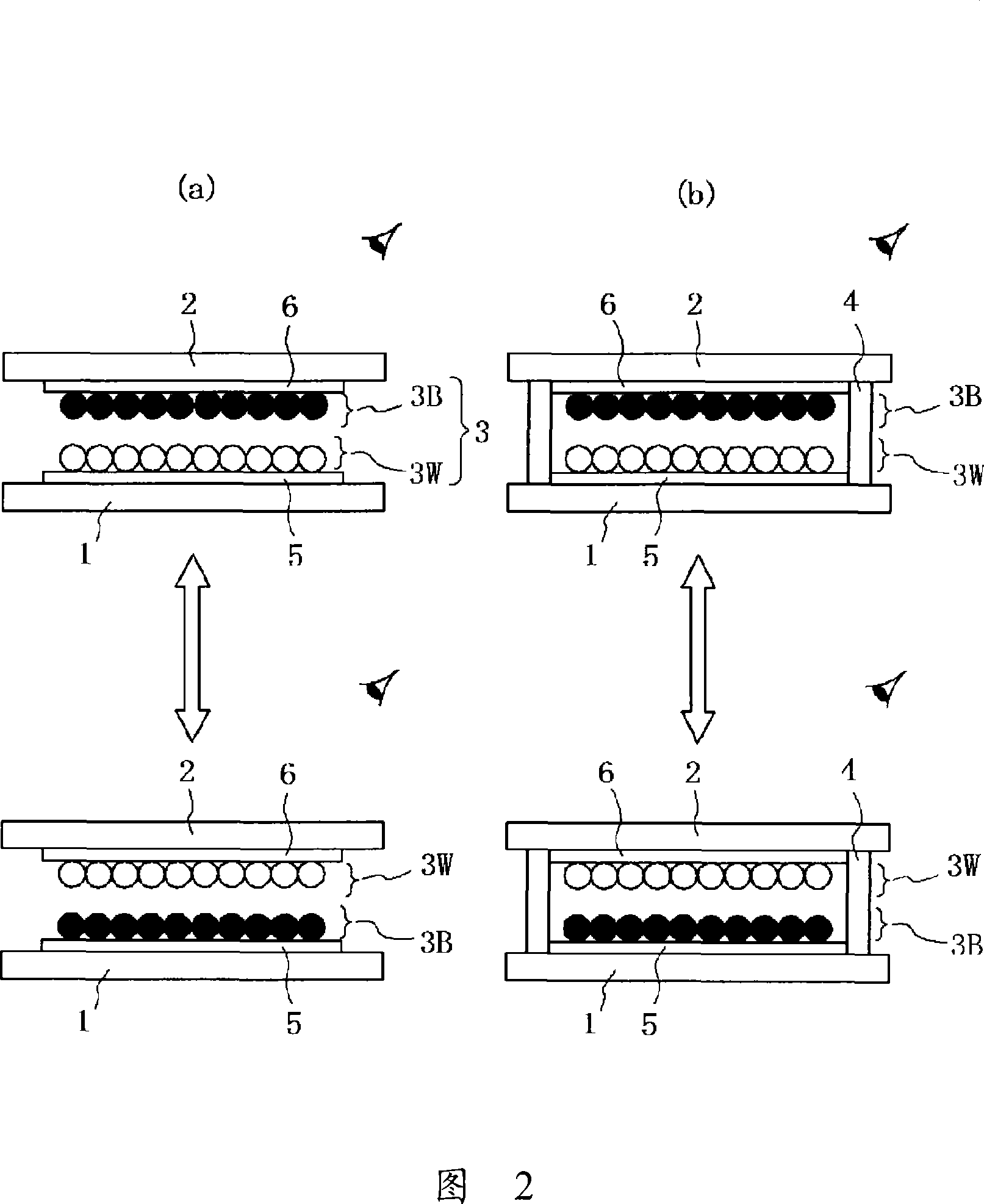

[0160] Through the display medium filling process shown in FIG. 5 , two types of particle groups (particle group A and particle group B) having different optical reflectance and charging characteristics are continuously filled into cells of one substrate in which partition walls are formed. The particle group A and the particle group B are filled with the same volume, and the combined volume occupancy of the two particle groups is adjusted to be 25 vol% with respect to the substrate space formed by laminating the two substrates. Next, the substrate in which the particle group is filled and arranged in the cell is superimposed on another substrate, and the outer peripheral part of the substrate is bonded and sealed with an epoxy-based adhesive, and the display medium (particle group A and particle group B) is enclosed. A panel for displaying information is prepared.

Embodiment 2

[0162] Through the display medium filling process shown in FIG. 6, two types of particle groups (particle group A and particle group B) having different optical reflectance and charging characteristics are filled in the cells of the substrate with partition walls and the other cell without partition walls. A substrate chamber. The particle group A and the particle group B are filled with the same volume, and the combined volume occupancy of the two particle groups is adjusted to be 25 vol% with respect to the substrate space formed by laminating the two substrates. Next, the two substrates in which the particle groups are filled and arranged in the small chamber are superimposed on each other, and the outer peripheral parts around the substrates are bonded and sealed with an epoxy-based adhesive, and the display medium (particle group A and particle group B) is sealed to prepare information. Display panel.

Embodiment 11

[0171] Two types of display media (particle group A and particle group B) of different charging characteristics, white and black, were successively filled into cells of one substrate with partition walls according to the display medium filling process shown in FIG. 11 . First, the black display medium (group of black particles) is filled, and the ion generator (SJ-F010 produced by KEYENCE CORPORATION.) is used to remove the static electricity, and then the white display medium (group of white particles) is superimposedly filled. Table 2 below shows the results of observation and evaluation of the state after the completion of the filling step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com