Twin-wheel caster

A technology of guiding rollers and double wheels, which is applied to casters, wheels, multi-purpose hand tools, etc., can solve the problems of roller function failure, damage, non-protection of grease outflow, etc., and achieve the effect of preventing pollution and preventing grease outflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

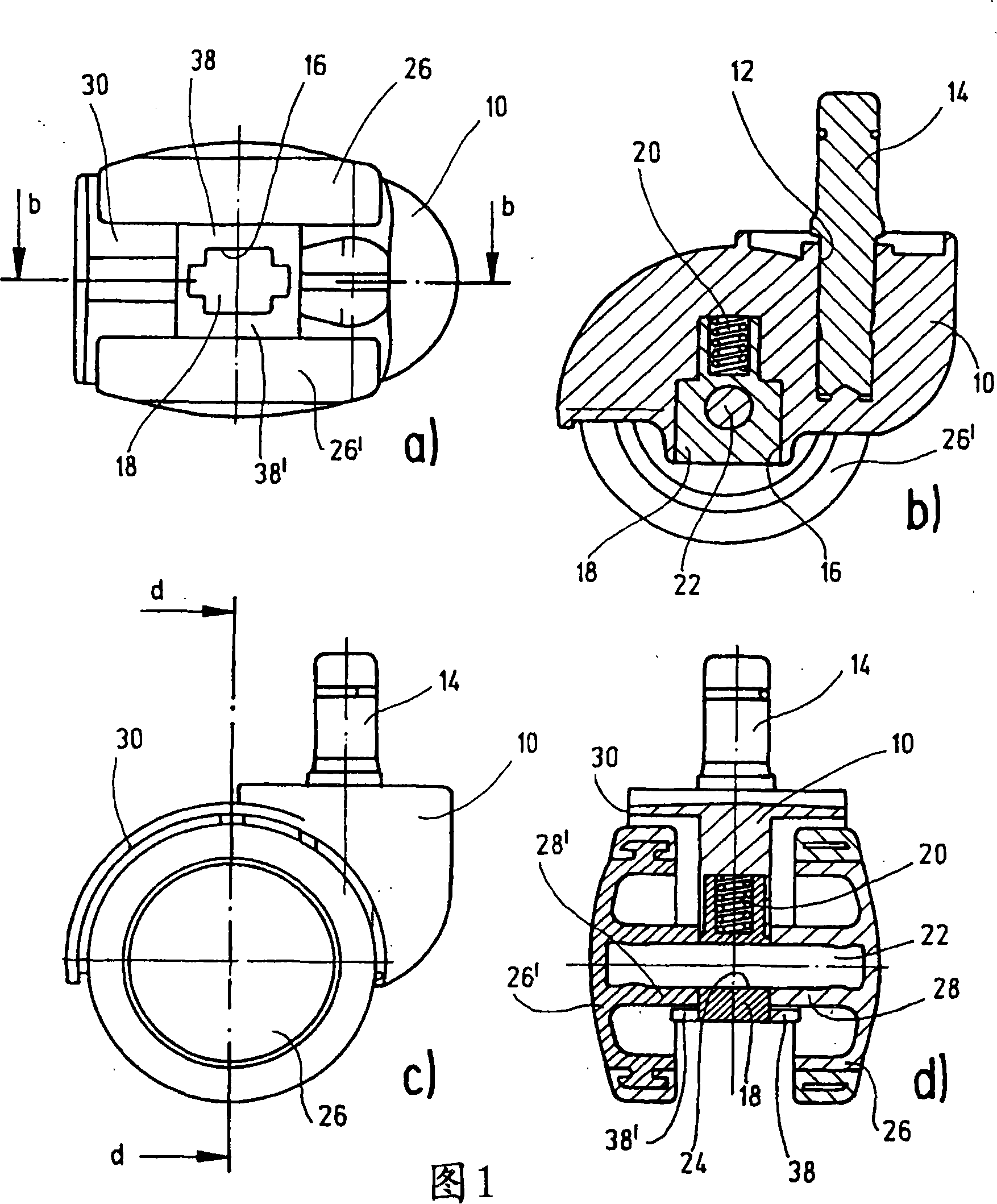

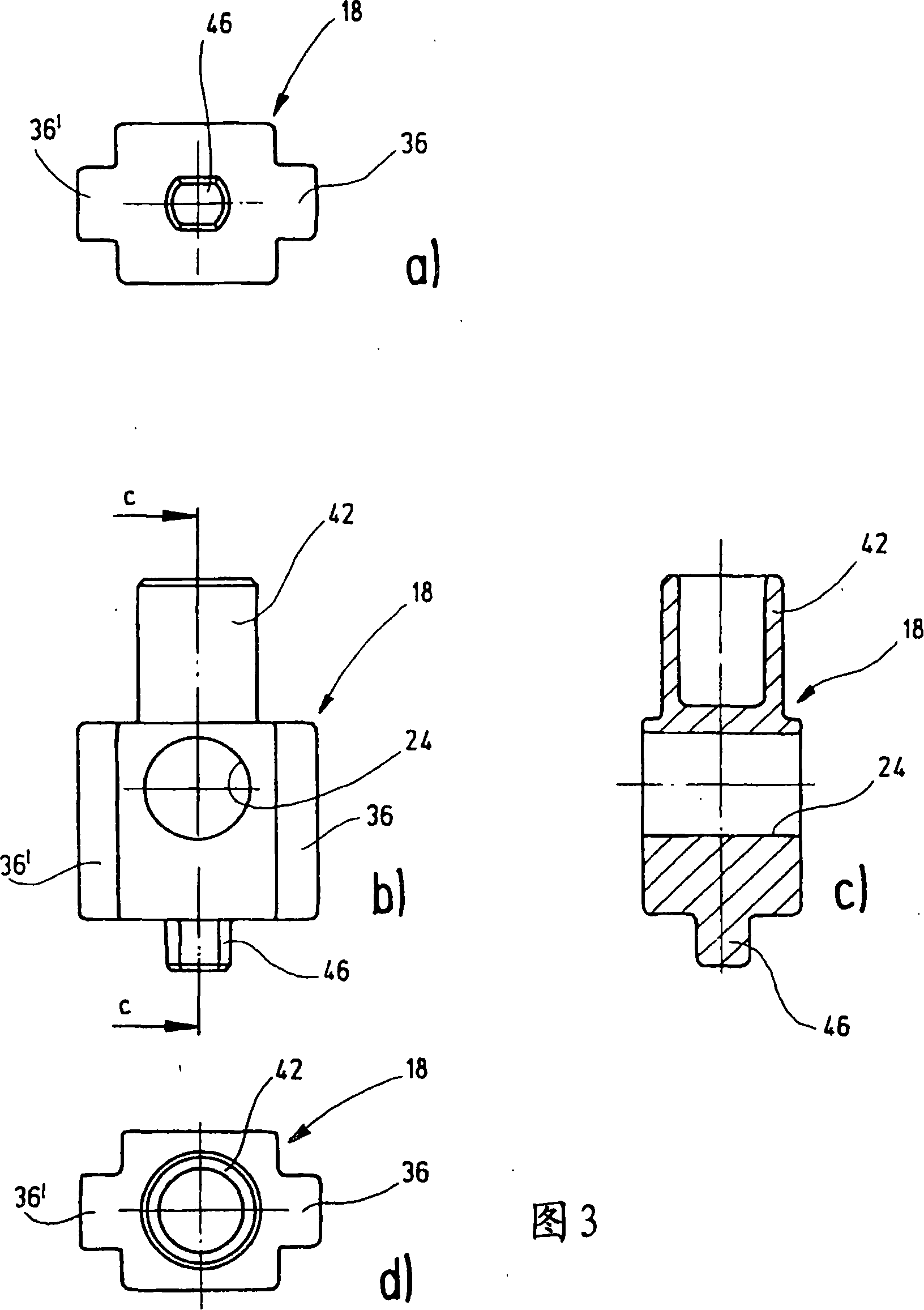

[0024] The roller (Fig. 1) shown in the figure mainly comprises a housing 10, a pin shaft 22 and two wheels 26, 26'; Here the swivel pin is rotatably fixed on a concrete or the like, and the housing 10 also has a spool hole 16 for accommodating the spool 18, which can overcome the force of the spring 20 in a rolling position and a braking position. Move vertically in the housing 10 between them; the pin shaft 22 is press-fitted in the through hole 24 of the spool valve 18 and arranged transversely to the spool valve hole 16; the wheels 26, 26' have tubular hubs 28, 28', The hub is sleeved on the free end of the pin shaft 22 and rotates on it. The wheel consists of a wheel body with cast-on running surfaces made of a material adapted to the intended application, and the rounded top 30 of the housing 10 covers the upper region of the wheels 26 , 26 ′.

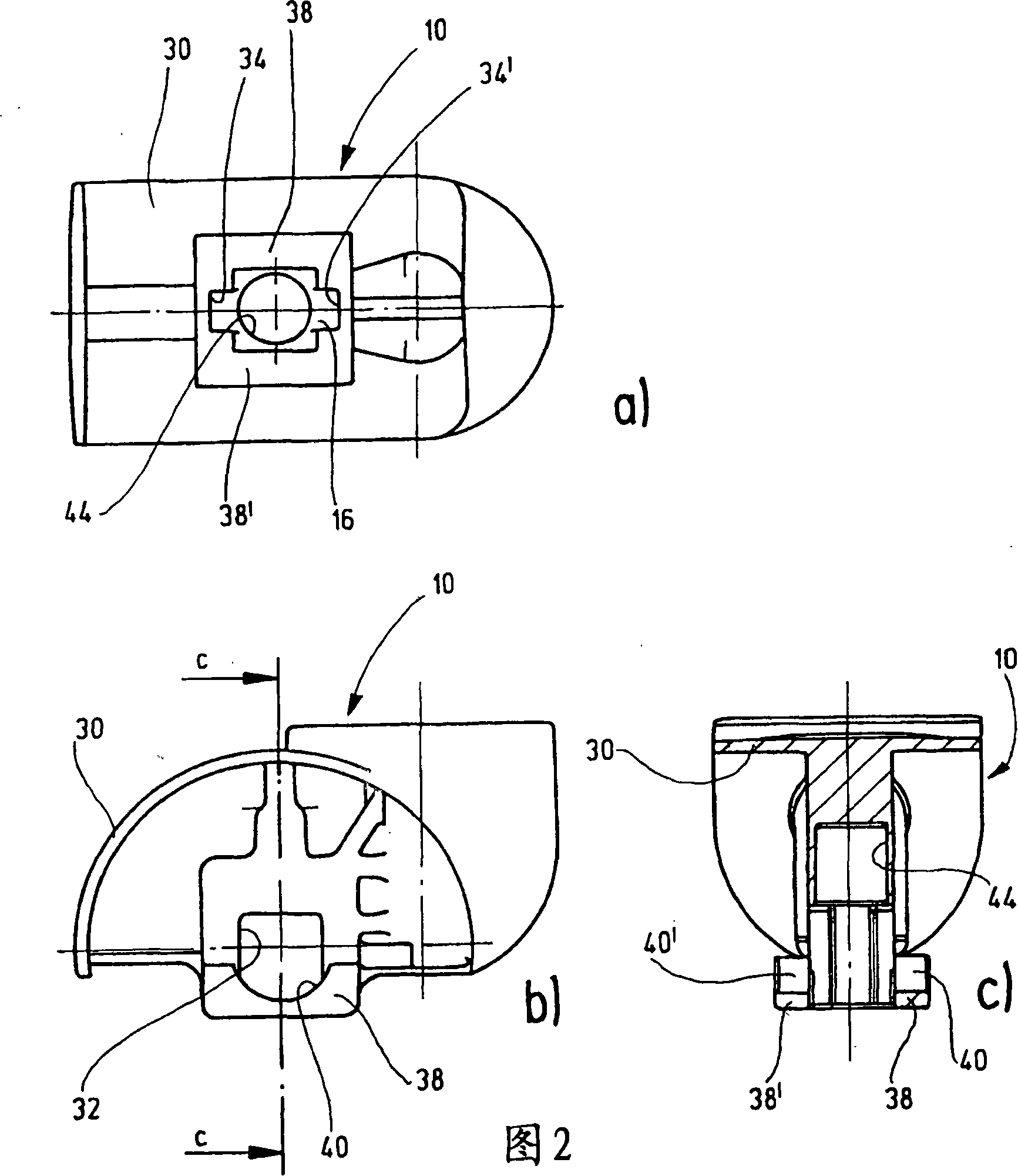

[0025] The housing ( FIG. 2 ) has a recess 32 in the region of the slide valve bore 16 , through which the slide valve 18 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com