Divided conductor powerline with loading ice melting scheme

A wire and ice-melting technology, which is applied in the installation of electrical components and cables, overhead installation, etc., can solve the problems of large power loss, many operations, and large investment, and achieve low power consumption, simple implementation, and high safety in melting ice Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

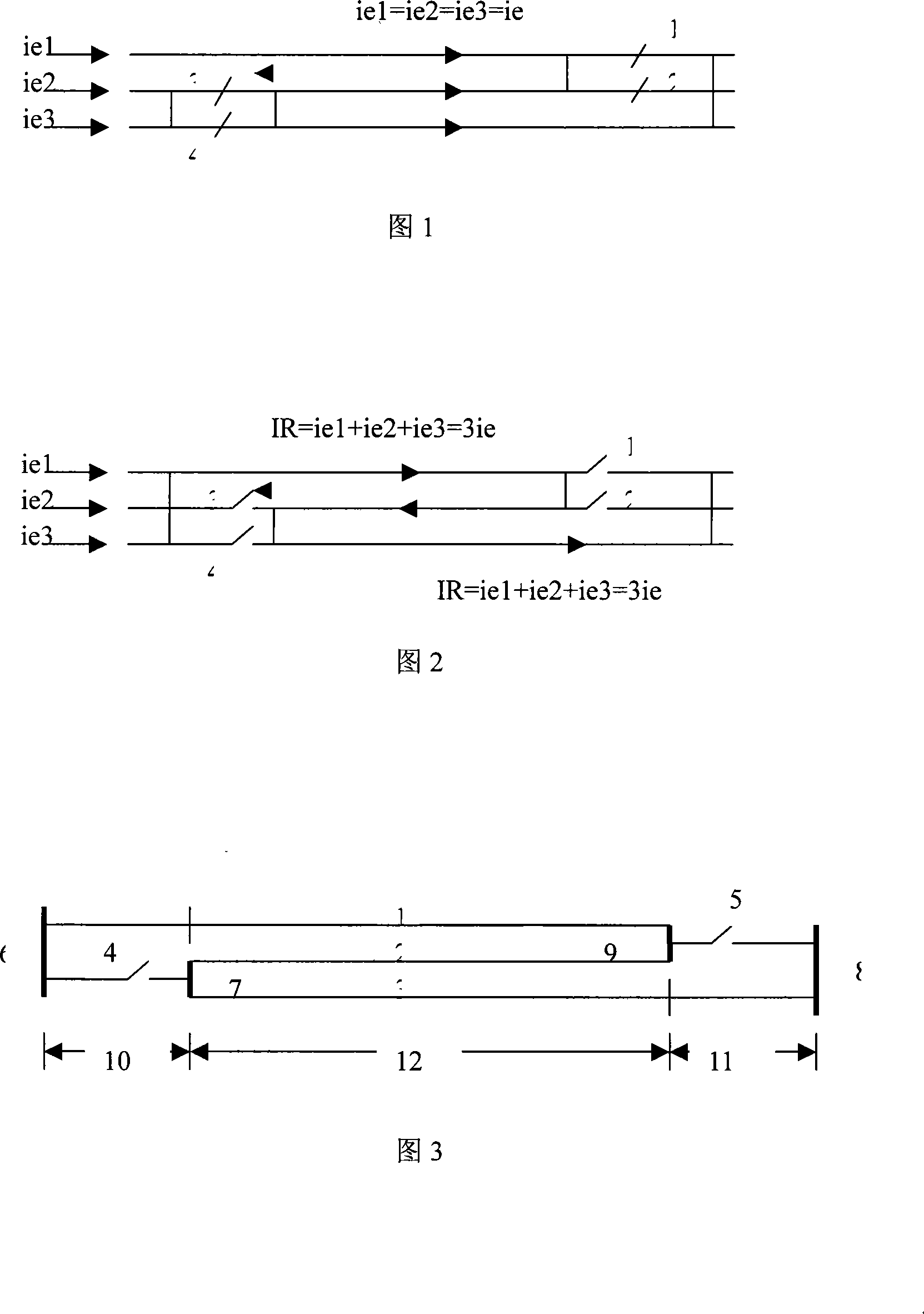

[0025] The ice-covered area of the new line adopts three-split conductors, and the cross-section of the conductors is still selected according to the economic current surface density, and implemented according to Figure 3, that is, to realize ice melting under load. The ice-covered tension-resistant section of the line that has been put into operation is assembled according to the accompanying drawing 3 by modifying the wires and the metal fittings of the wires, and adding two sets of isolation switches and four sets of diversion plates to realize ice melting under load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com