Fourth roller speed automatic regulating device

An automatic adjustment, the fourth technology, applied in the direction of textiles and papermaking, continuous winding spinning machines, spinning machines, etc., can solve the problems of unable to realize the process of gathering fiber strands, mixing different fibers, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

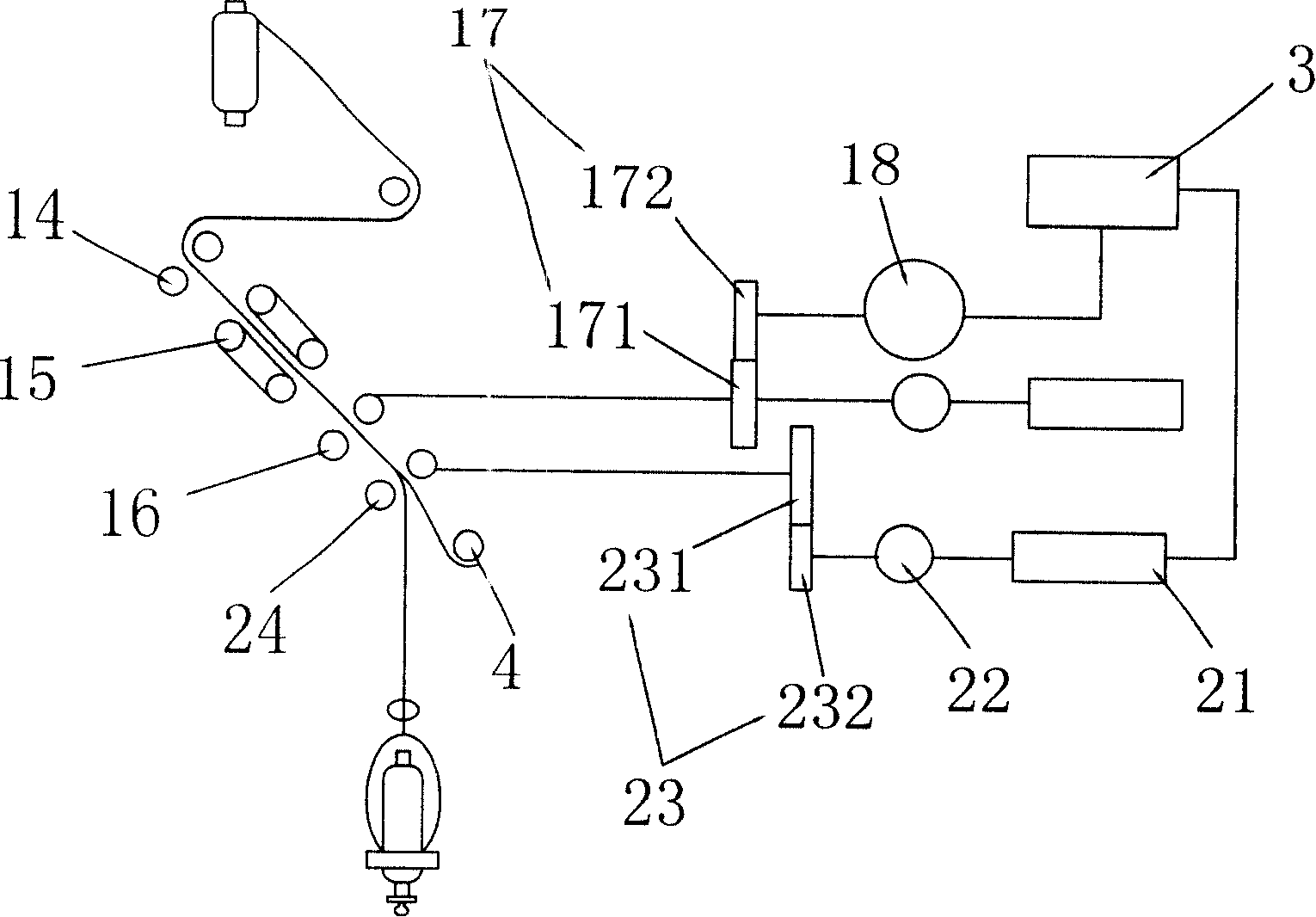

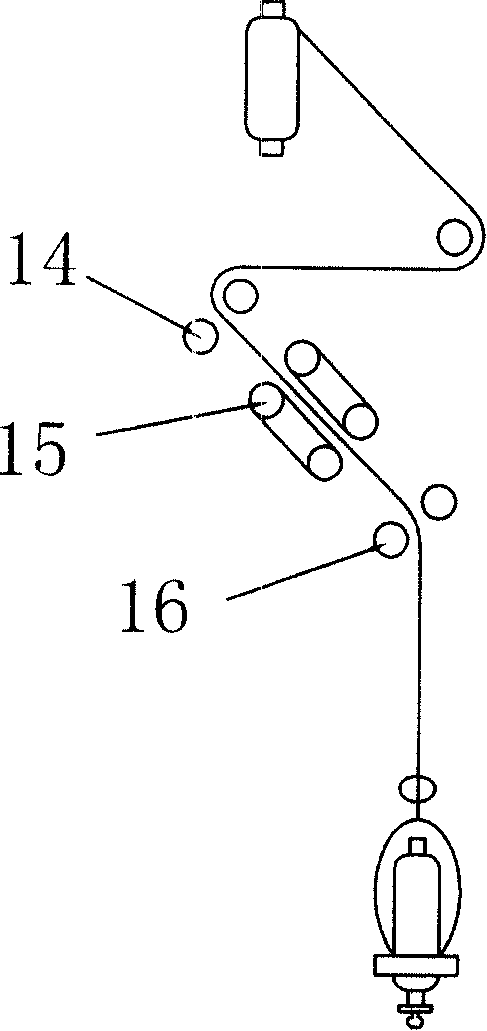

[0018] Such as figure 1 , image 3 Shown: The fourth roller speed automatic adjustment device mainly includes the front roller signal output device 1, the fourth roller driver 2 and the fourth roller speed automatic adjustment device 3, the front roller signal output device 1 converts the rotation signal of the front roller into an angle The analog signal, the fourth roller speed automatic regulator 3 receives the angle analog signal, issues instructions and controls the movement of the fourth roller driver 2 . The fourth roller driver 1 mainly includes: a driver 21, a servo motor 22, a reduction gear pair 23 and a fourth roller 24 placed between the front roller mouth 13 and the jaw 4, a gear of the reduction gear pair 23 231 is installed on the fourth roller 24 axle ends, and another gear 232 is contained on the output shaft of servo motor 22. Described front roller out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com