A mixed mode expansion plate of automobile safety air bag

A vehicle safety and deployment panel technology, which is applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle components, etc., can solve problems such as cracking of the instrument panel skeleton, affecting the normal deployment of airbags, and unstable flipping, etc., to improve stability. , Guarantee position stability and installation reliability, strengthen the effect of guiding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

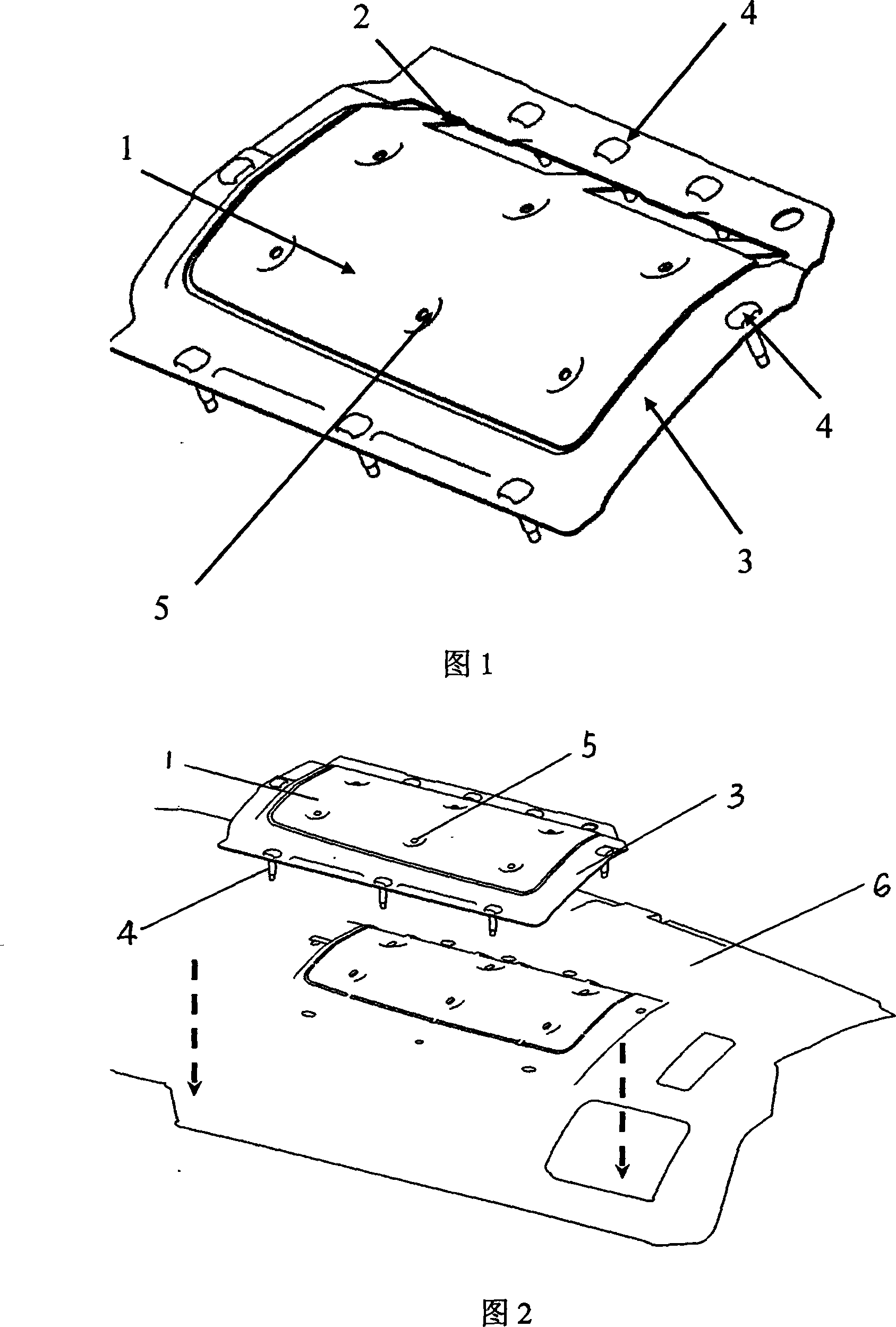

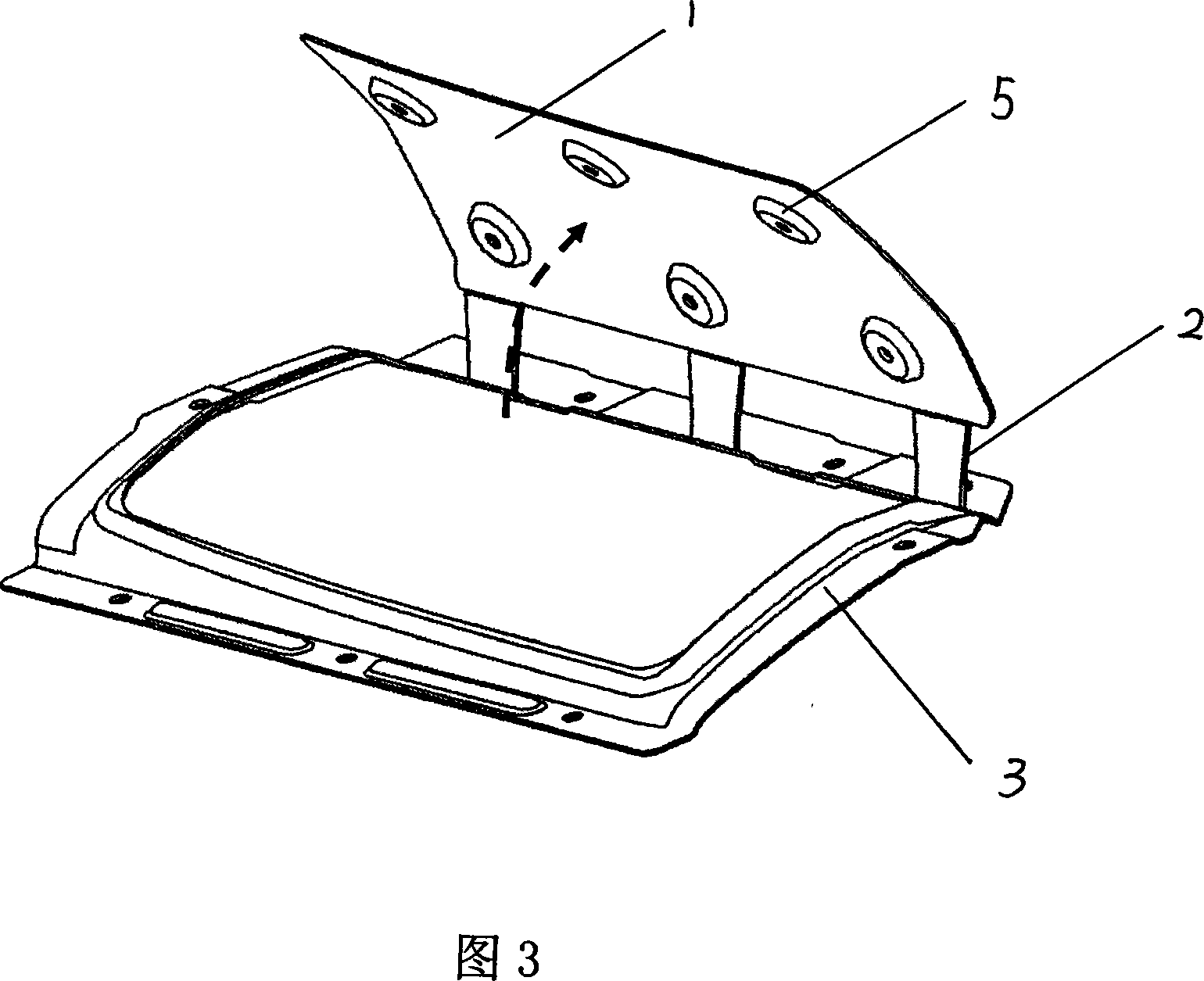

[0018] Referring to Fig. 1, the airbag composite deployment panel includes a deployment panel body 1 and a deployment panel frame 3, which are made of steel materials. The expansion plate body 1 is located in the expansion plate frame 3, and the two are connected by three straight hinges 2. The entire expansion plate body is a nearly rectangular arc-shaped plate, and six counterbores 5 are uniformly arranged on the expansion plate body 1. Projection welding bolts 4 are arranged on the frame 3 .

[0019] Referring to FIG. 2 , during installation, the frame 3 of the unfolded panel is fixedly connected with the instrument panel body 6 through projection welding bolts 4 . The expansion panel body 1 is connected with the expansion panel frame 3 through a straight hinge 2, and riveted to the instrument panel body 6 through six countersunk holes, and then the entire instrument panel is foamed to complete the skinning process, so that the expansion panel is placed on the instrument pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com