Programmable logic controller module assembling mode

A controller module, programming logic technology, applied in sequence/logic controller program control, electrical program control and other directions, can solve the problems of high manufacturing cost, increased manufacturing cost, large terminal shape, etc., to achieve the limit and Simple and reliable fixing, quick and convenient installation and maintenance, safe and reliable wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is specifically introduced as follows:

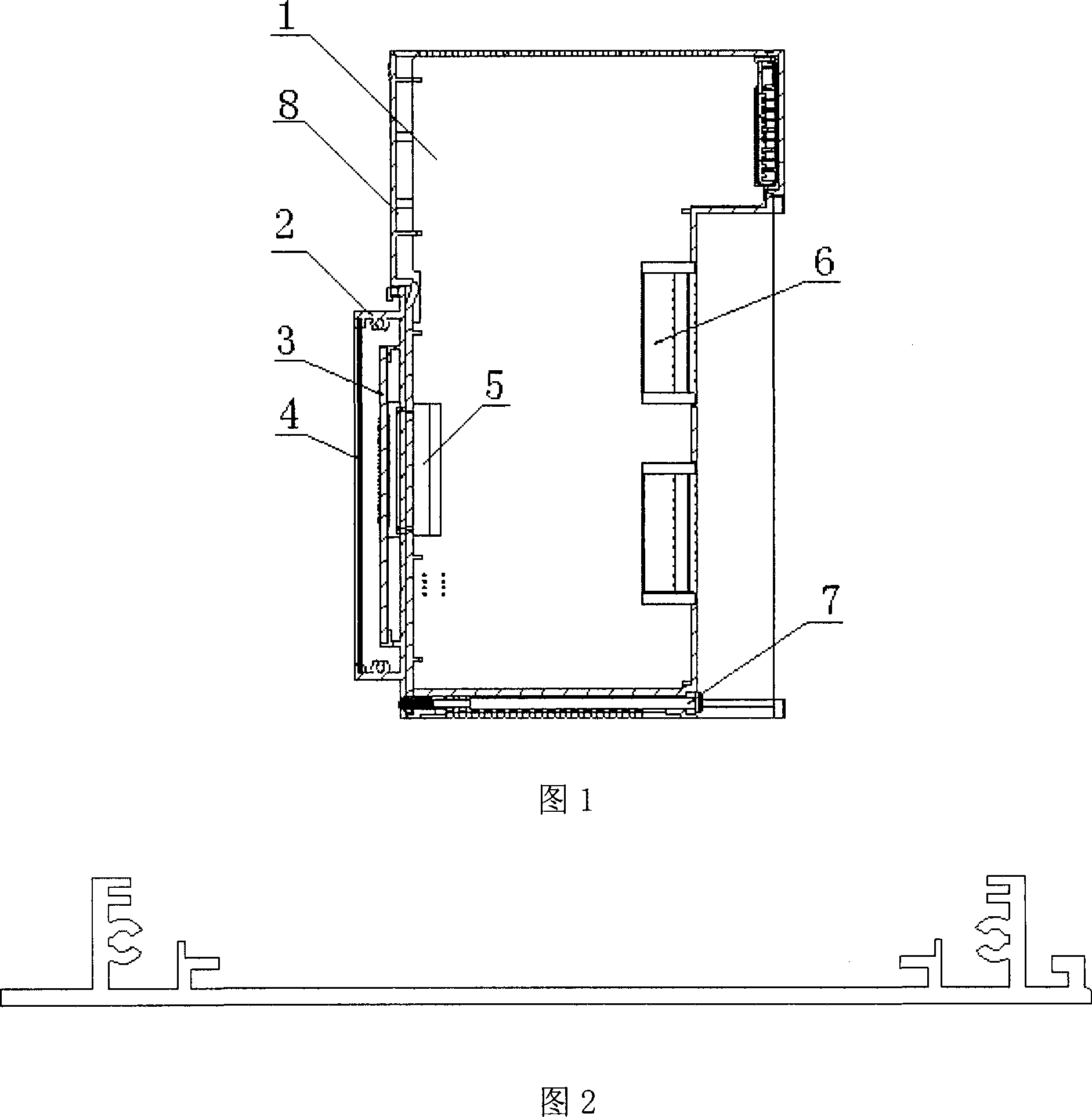

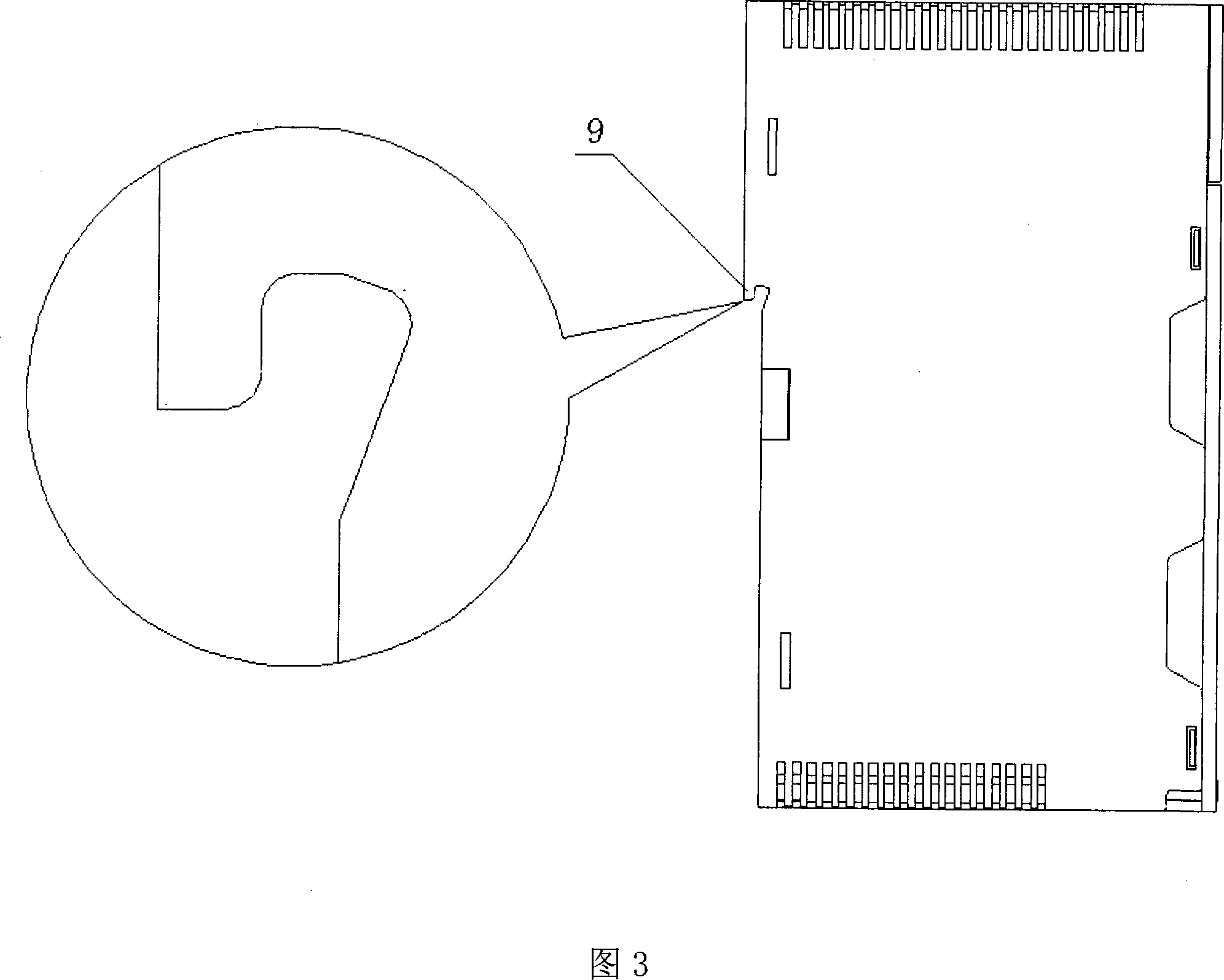

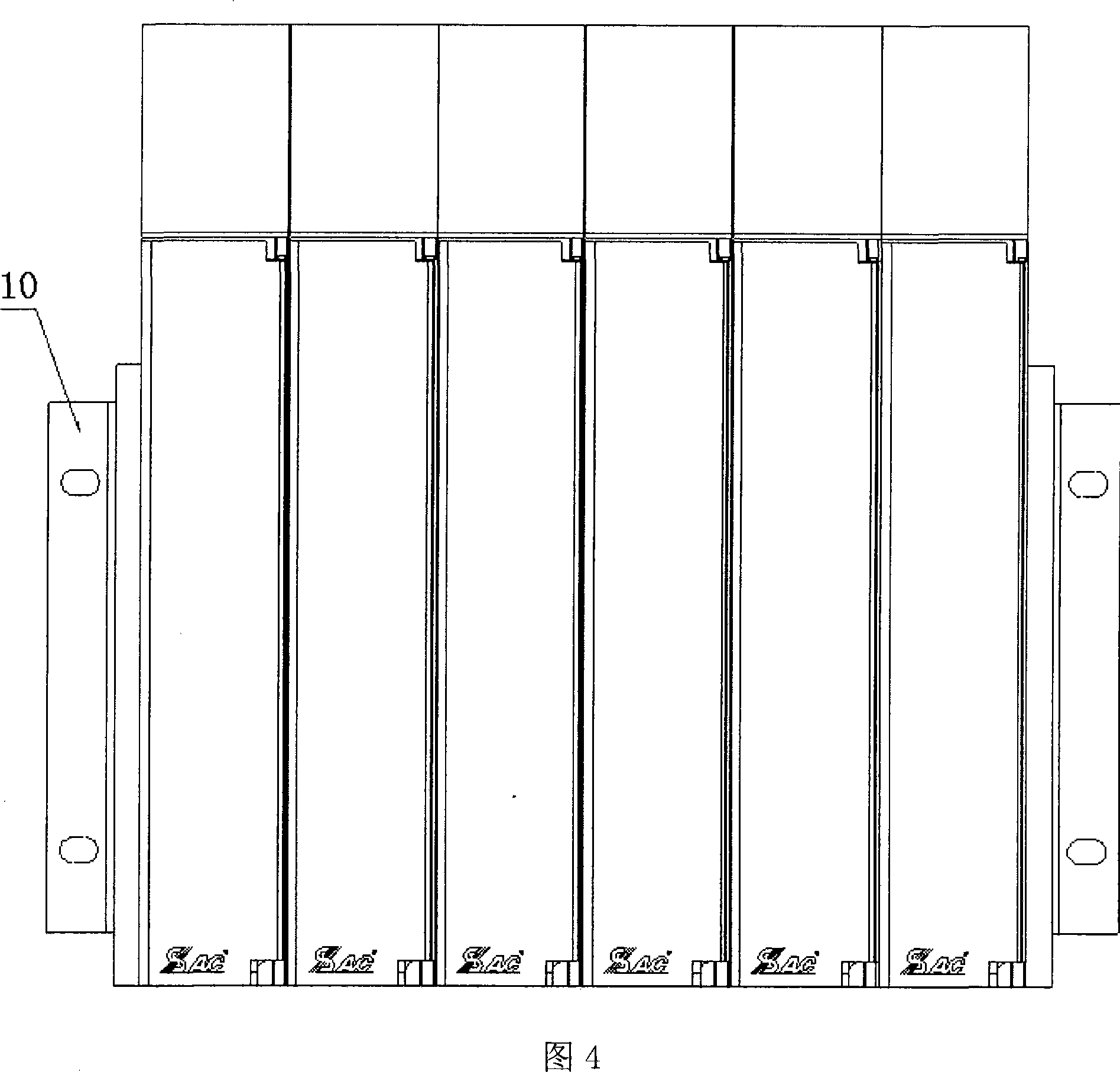

[0027] Fig. 1 is a schematic diagram of the connection method of the present invention; Fig. 2 is a cross-sectional view of a base plate skeleton in the present invention; Fig. 3 is a schematic diagram and a partial enlarged view of a hook on a module in the present invention; Fig. 4 is a left view of Fig. 1; Fig. 5 is a schematic diagram and a partially enlarged view of the wire harness constraint points on the module in the present invention.

[0028] As shown in the figure, the assembly method of the programmable logic controller module of the present invention includes the assembly of a single module, the assembly of the installation base, and the assembly of the module and the installation base.

[0029] As shown in Figure 1, the principle of single-module assembly is that a printed board 1 integrates all components, including connectors 5 and terminals 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com