Centrifugal method for extracting sugar juice from sugar-cane and sweet Chinese sorghum stalk

An extraction method and technology of sweet sorghum are applied in the extraction of sugar juice from sweet sorghum stalks and in the field of sugar cane, achieving the effects of convenient debugging and maintenance, less application equipment and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

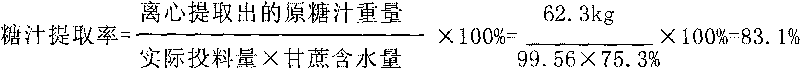

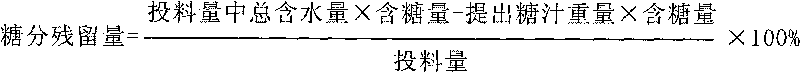

[0052] Example 1: Extraction of raw sugar juice with sugarcane and extraction of residual sugar from its residue.

[0053] ① Weigh 100kg of cane stems and stalks without cane roots, leaves and cane sheaths, and take a small sample for measurement; sugar content is 16.7%, reducing sugar is 0.85%, crude fiber is 6.3%, ingredients are 0.8%, organic non-sugar content is 1%, moisture content is 75.3% %

[0054] ②Put the sugarcane into a fast-rotating stalk cutting and granulating machine (UE series stalk cutting and granulating machine produced by Xiamen Wuhua Tianbao Biological Engineering Co., Ltd.). 0.2-3mm, 0.2-1.5mm thick, thin strips and fine needles or small flakes of hard fibers that have been separated from the pulp core; at the same time, the sugar-filled pulp core composed of countless vascular bundles without fibers has been cut into about Small particles with a diameter of about 1-3mm. Due to the fast cutting speed and the extremely brittle sugarcane, the mixture of ...

Embodiment 2

[0063] Example 2: Extraction of raw sugar juice with sweet sorghum stalks and extraction of residual sugar from its residue

[0064] ① Weigh 100 kg of sweet sorghum stalks without sweet sorghum roots, leaves and small spike heads, and take a small sample to measure the sugar content of 17.2%, reducing sugar 1.1%, crude fiber 7.4%, ash content 0.92%, organic non-sugar content 1.2% %, moisture 73.8%.

[0065] ②Put the sweet sorghum stalks into a fast-rotating stalk cutting and granulating machine (UE series cutting and granulating machine produced by Xiamen Wuhua Tianbao Biological Engineering Co., Ltd.), the hard and dense outer skin of the sweet sorghum stalks is quickly cut to grow 10-45mm in width. 0.2-1.5mm has been detached from the pituitary thin strips and needles or small flake-like fibers, and the fiber-free pulp core composed of countless vascular bundles is also cut into small particles with a diameter of about 1-3mm very quickly mixture with a volume of 0.61m 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com