A paper napkin humectation device

A technology of paper towels and moistening paper, which is applied in the field of sanitary ware machinery, and can solve problems such as the inability to provide moist paper towels immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

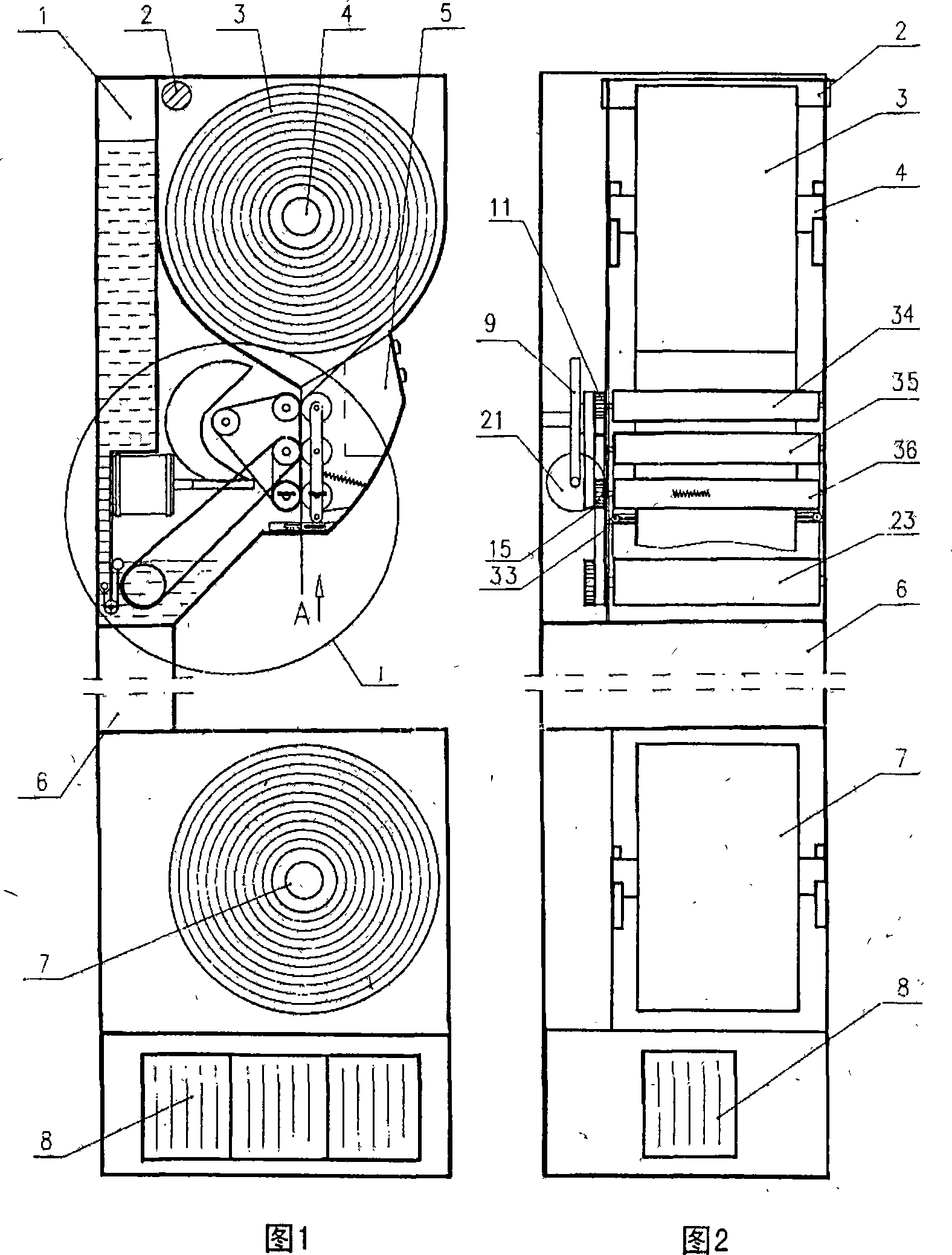

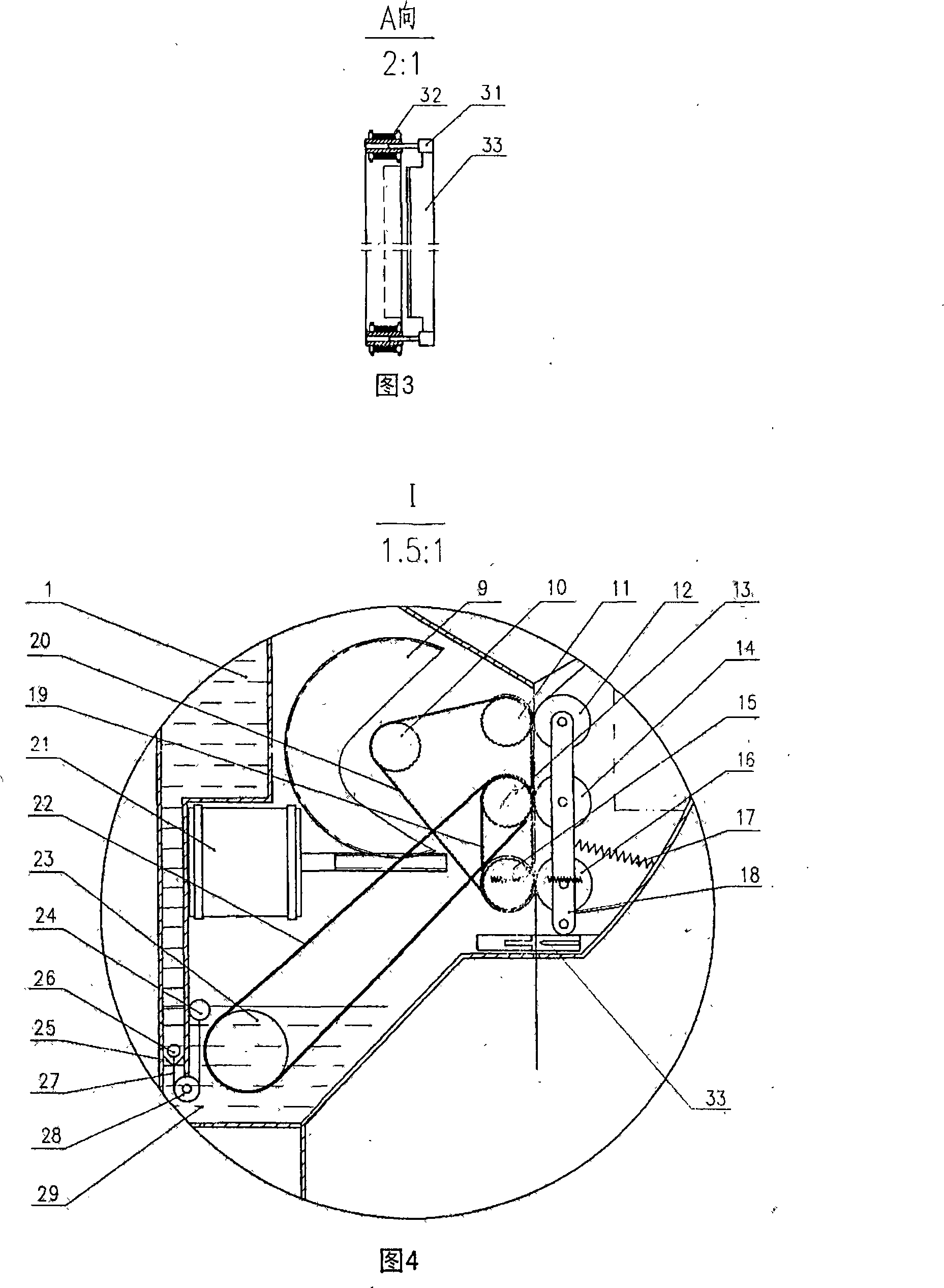

[0015] As shown in Fig. 1, the paper towel wetting mechanism is composed of the dampening power roller 35, the dampening driven roller 14, and the paper towel soaking belt 22, and the dampening power roller 35 and the dampening driven roller 14 constitute a pair of frictions through which the paper towels can pass. The transmission pair, the moistening power roller 35 is wound with a paper towel soaking belt 22, and the paper towel soaking belt 22 is provided with non-wetting sections at equal intervals, and the distance between the sections is 1 / 2 to 1 / 8 of the circumference of the paper towel soaking belt , the interval width is 2-15 mm, and the length is equal to the width of the paper towel soaking belt; the bottom of the paper towel soaking belt 22 is soaked in the liquid in the liquid storage chamber 1, and the paper towel soaking belt 22 carrying the wetting liquid wets the paper towel intermittently.

[0016] The above-mentioned non-wetting section can be made of a shee...

Embodiment 2

[0018] In the paper towel wetting mechanism described in Embodiment 1, referring to FIG. 2 , a roller 23 in the liquid storage chamber is also installed in the liquid storage chamber 1, and the roller 23 in the liquid storage chamber and the power roller 35 for moistening paper form a wetting state through the wetting belt 22 of the paper towel. wet body.

Embodiment 3

[0020] Referring to Fig. 4, in the paper towel wetting mechanism of the present invention, a power transmission wheel 10, a paper feeding power wheel 11, a heating paper guiding power wheel 15 are connected with a synchronous pulley belt 20 to form a synchronous transmission pair, and the power is driven by the control circuit system 5 The transmission wheel 10 drives the synchronous transmission pair to complete the paper feeding and soaked paper export; the heating paper guide power wheel 15 and the moistening power roller 35 form a synchronous transmission pair, and the two wheels form a set of synchronous belt transmission structure to drive the moistening power roller 35 Rotate; heater can also be established in the heating guide power wheel 15, the paper towel that moistens is heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com