Cylinder injection type spark ignition internal combustion engine

A technology of spark ignition and in-cylinder injection, which is applied in spark ignition controllers, internal combustion piston engines, spark plugs, etc., to achieve the effects of good stratified combustion, promoting mixing, and suppressing attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

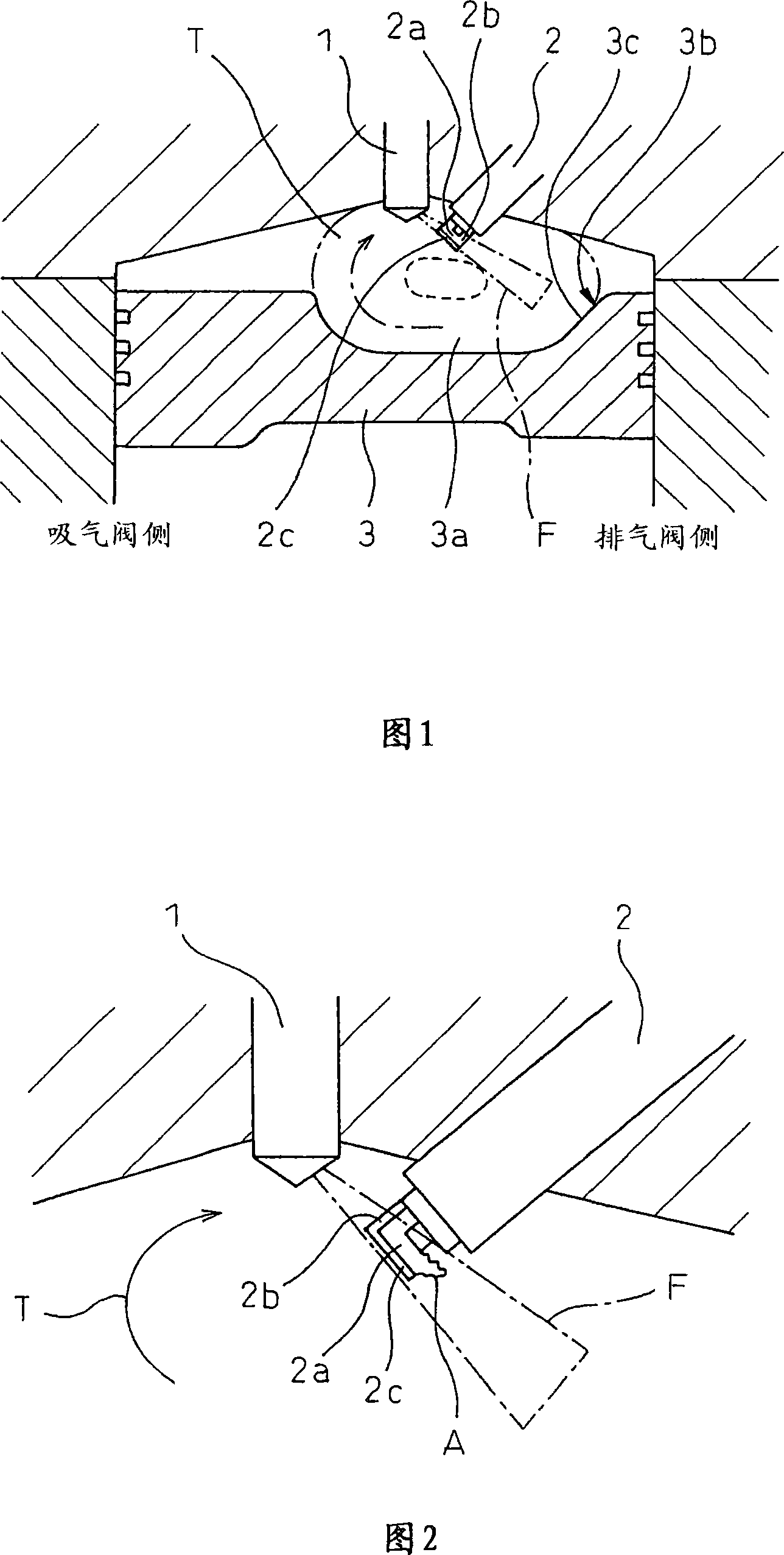

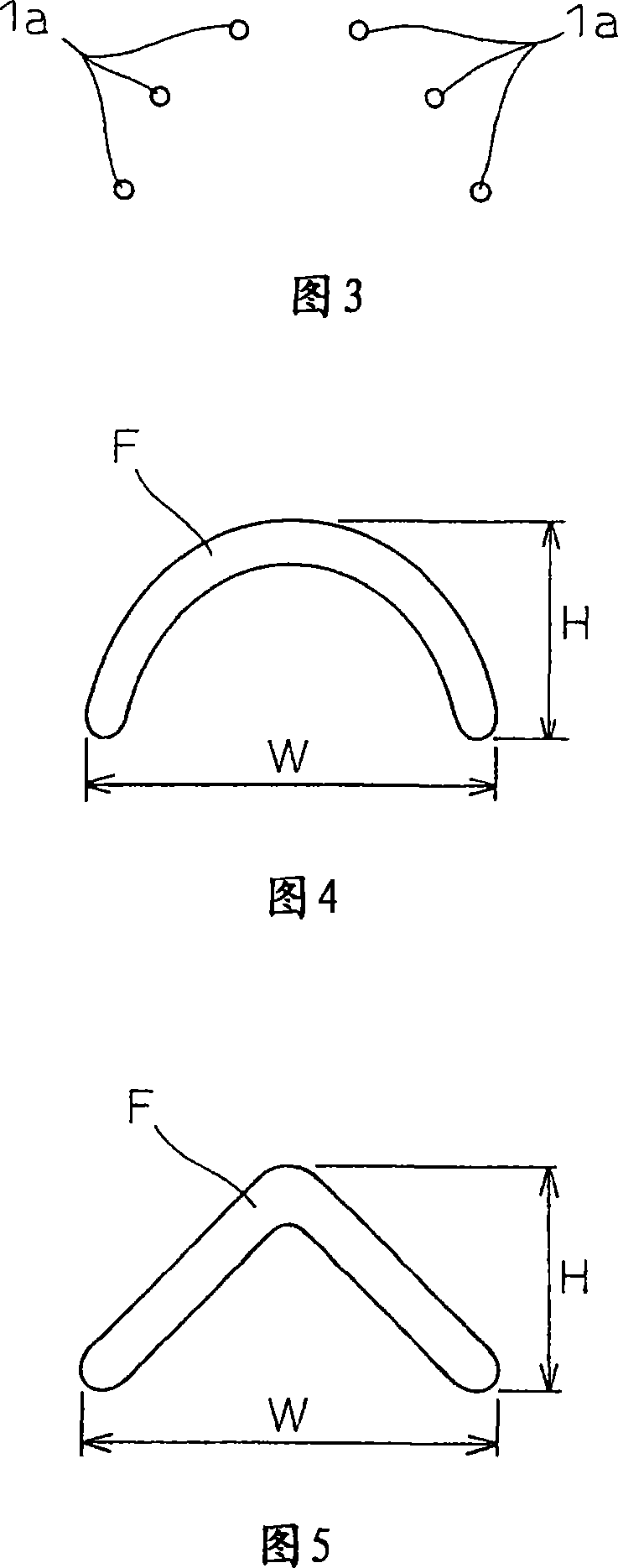

[0027] FIG. 1 is a schematic longitudinal sectional view showing an embodiment of an in-cylinder injection type spark ignition internal combustion engine according to the present invention. In the figure, 1 is a fuel injection valve for directly injecting fuel arranged at the approximate center of the upper part of the cylinder, and 2 is an ignition plug arranged near the fuel injection valve 5 on the side of the exhaust valve. This in-cylinder injection spark ignition internal combustion engine has two intake valves and two exhaust valves. Figure 1 is a cross-sectional view passing between the two intake valves and the two exhaust valves, so the intake air is not shown. valve and exhaust valve. In Fig. 1, the left side is the intake valve side, and the right side is the exhaust valve side.

[0028] 3 is a piston, and an air chamber 3a is formed on its top surface which is close to the exhaust valve side. The air chamber 3a has a smooth inner wall adapted to allow the tumble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com