Sliding desk type casing tube abrasion testing machine

A wear test, testing machine technology, applied in the direction of testing wear resistance, testing of machine/structural components, measuring devices, etc., to achieve the effect of adjustable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

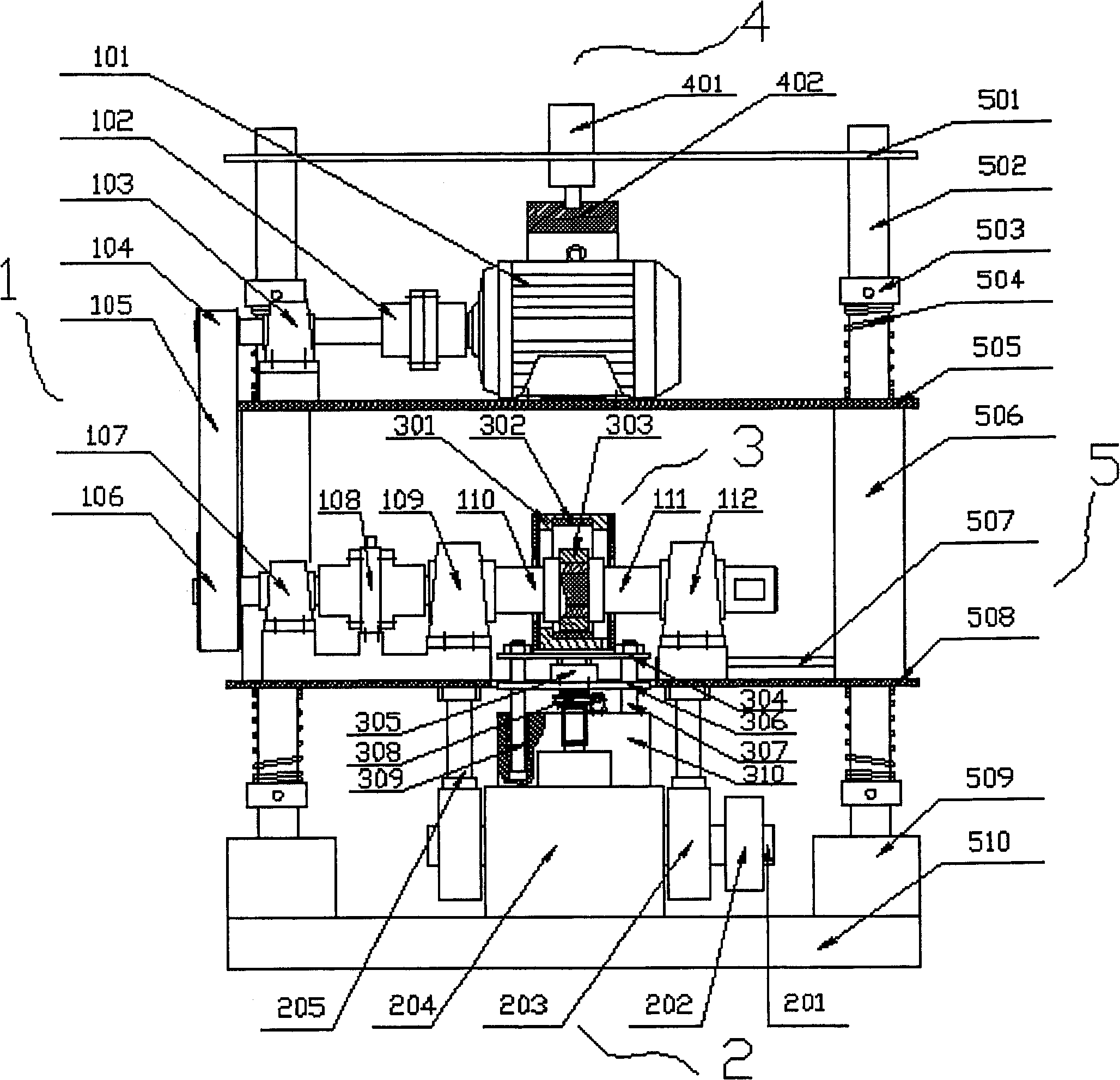

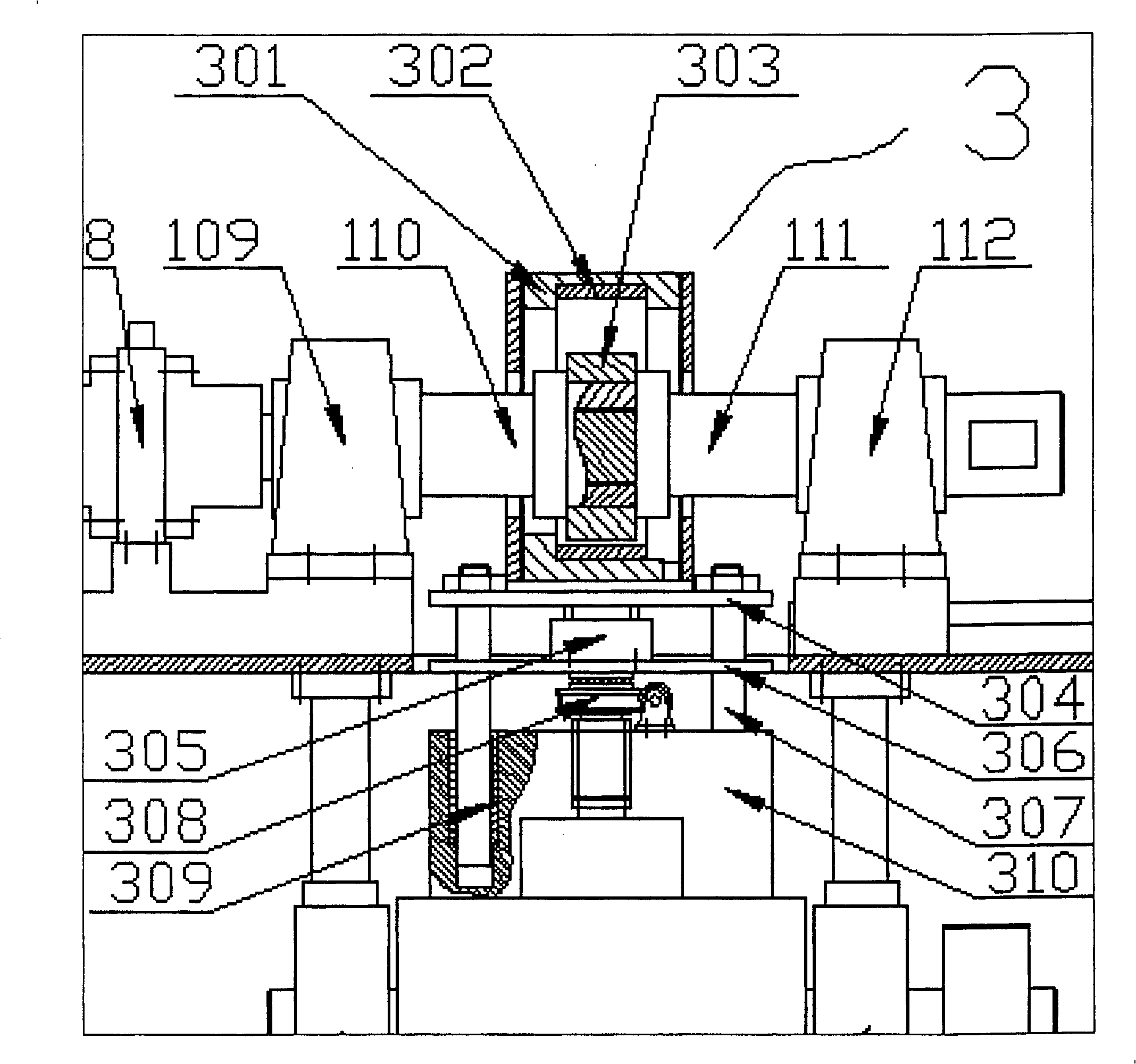

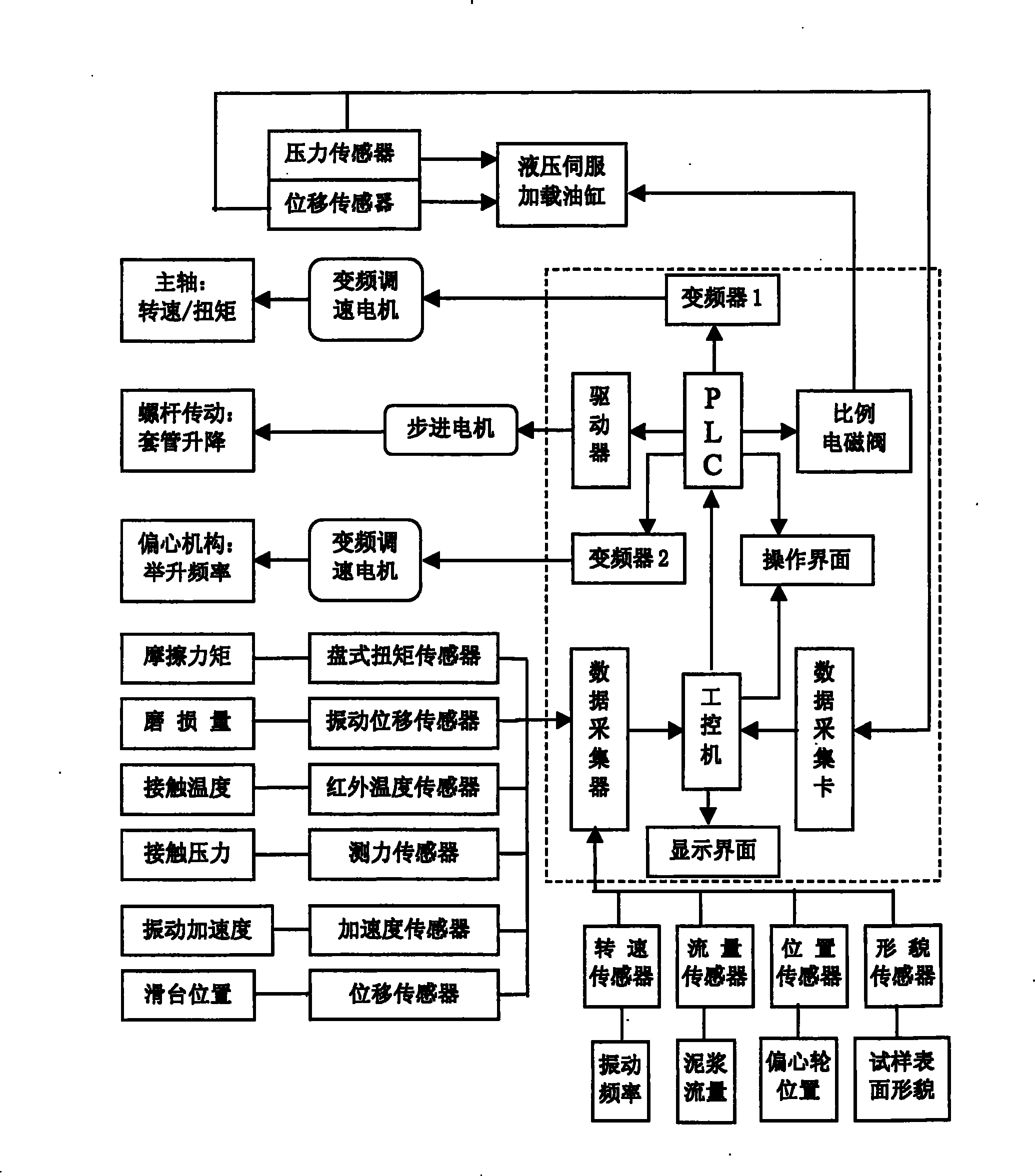

[0047] Such as Figure 1 to Figure 4 As shown, the present invention proposes a sliding table type casing wear tester, which includes a transmission system 1, an excitation system 2, a clamping system 3 and a frame 5, and the rotating transmission shaft 110 of the transmission system 1 is fixedly clamped with the first A test piece, the clamping system 3 is equipped with a second test piece corresponding to the first test piece, the transmission system 1 drives the first test piece to rotate around the axis, and the frame 5 is provided with at least one sliding platform. The transmission system 1 is arranged on the sliding platform, and the vibration excitation system 3 can drive the sliding platform to vibrate up and down, that is, the vibration excitation system 2 can drive the transmission system to vibrate up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com