Piezoelectric ignition device

An ignition device and piezoelectric technology, which are applied in the ignition, combustion ignition, and combustion methods of electric sparks, etc., can solve the problem of insufficient contact area between piezoelectric ceramics and tensioning blocks, insufficient axial thrust of piezoelectric ceramics, and parts processing. Tolerance requirements are high, to achieve the effect of simple manufacturing process, low manufacturing cost and strong output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

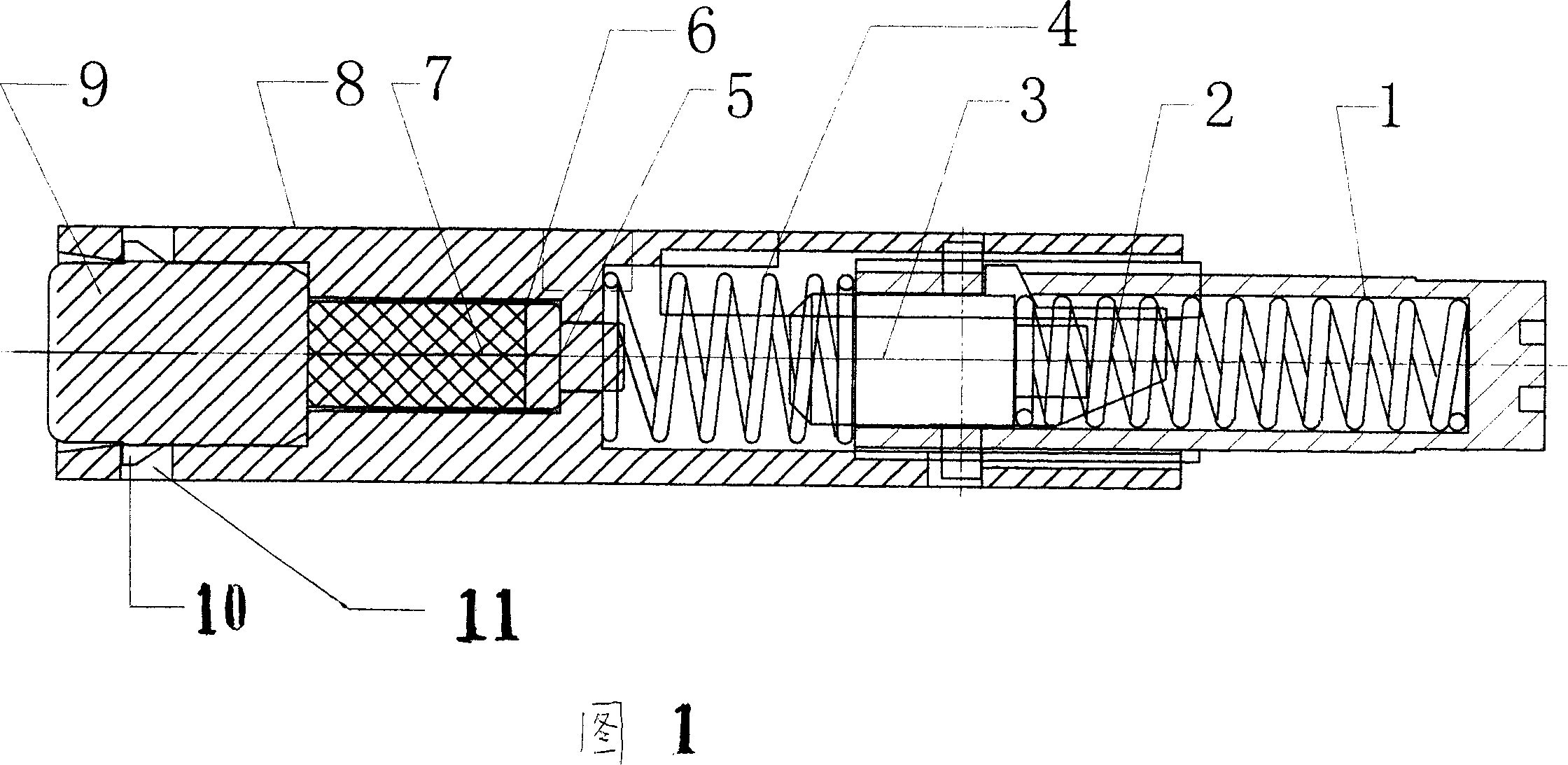

[0007] As shown in Figure 1, the present invention includes a housing 8, a button 1, a striker 2, a striker 3, a return spring 4, a contact 5, a piezoelectric ceramic 7 and a fixed pressing mechanism, which is a pad Block 9, the spacer block can be made of metal materials such as iron and copper, and the spacer block is installed in the shell with an inlaid structure.

[0008] In the figure, the cushion block 9 is in the form of a rectangular parallelepiped. A set of corresponding sides of the rectangular parallelepiped is provided with a hook 10 and a button hole 11 is provided at a corresponding position of the housing. The cuboid block 9 can be provided with hooks 10 on the two sets of corresponding sides, and correspondingly, button holes 11 are also provided on the shell. In addition, the shape of the cushion block 9 can also be a cylinder. At least three hooks are provided on the side of the cylinder in an equal arc, and a buttonhole is provided at the corresponding position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com