Gas flow generator

A generator and airflow technology, applied in the field of innovative design, can solve the problem of inconvenient application of heat dissipation components, achieve the effect of effective wind-driven heat dissipation, solve the volume problem, and effectively heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

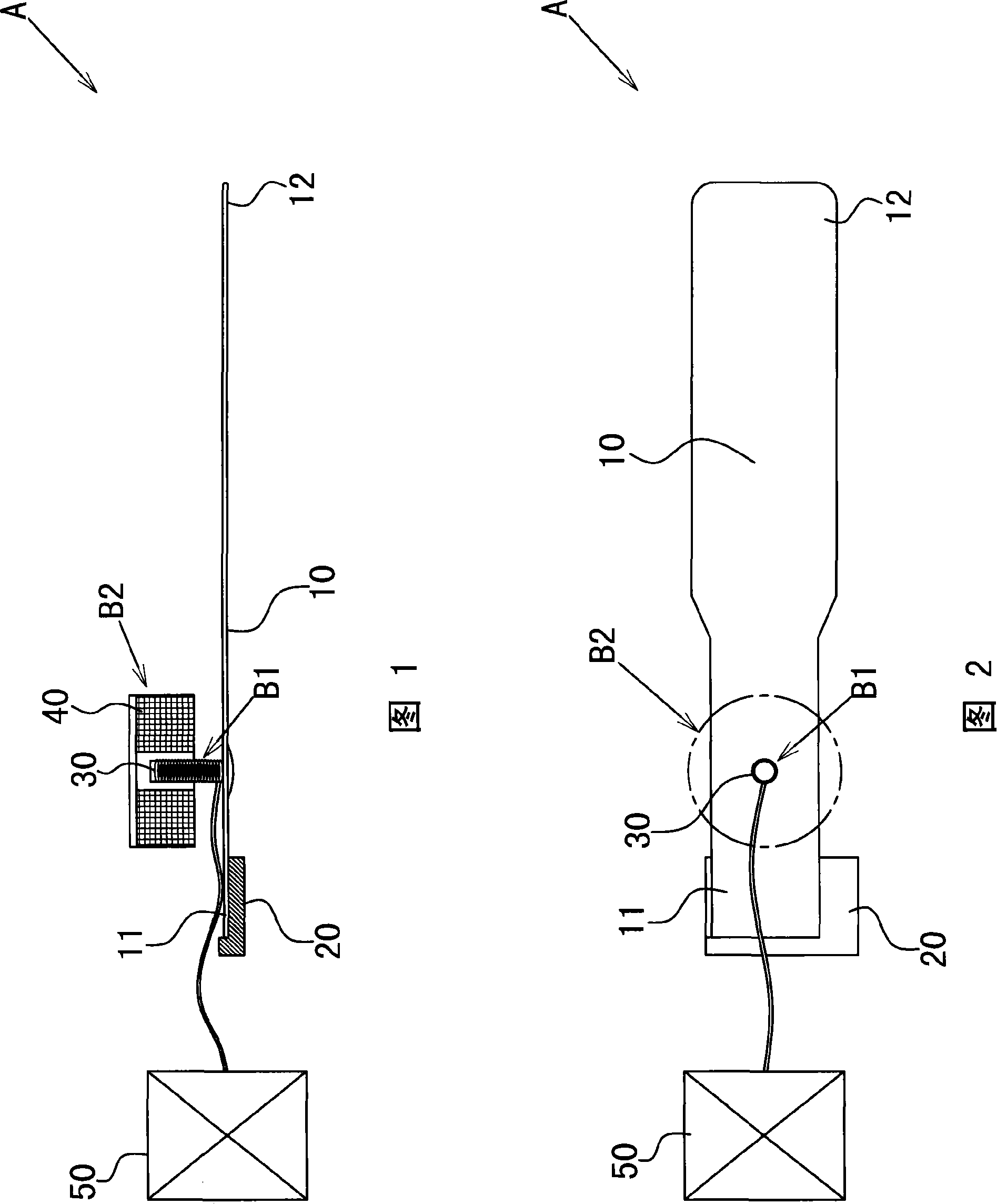

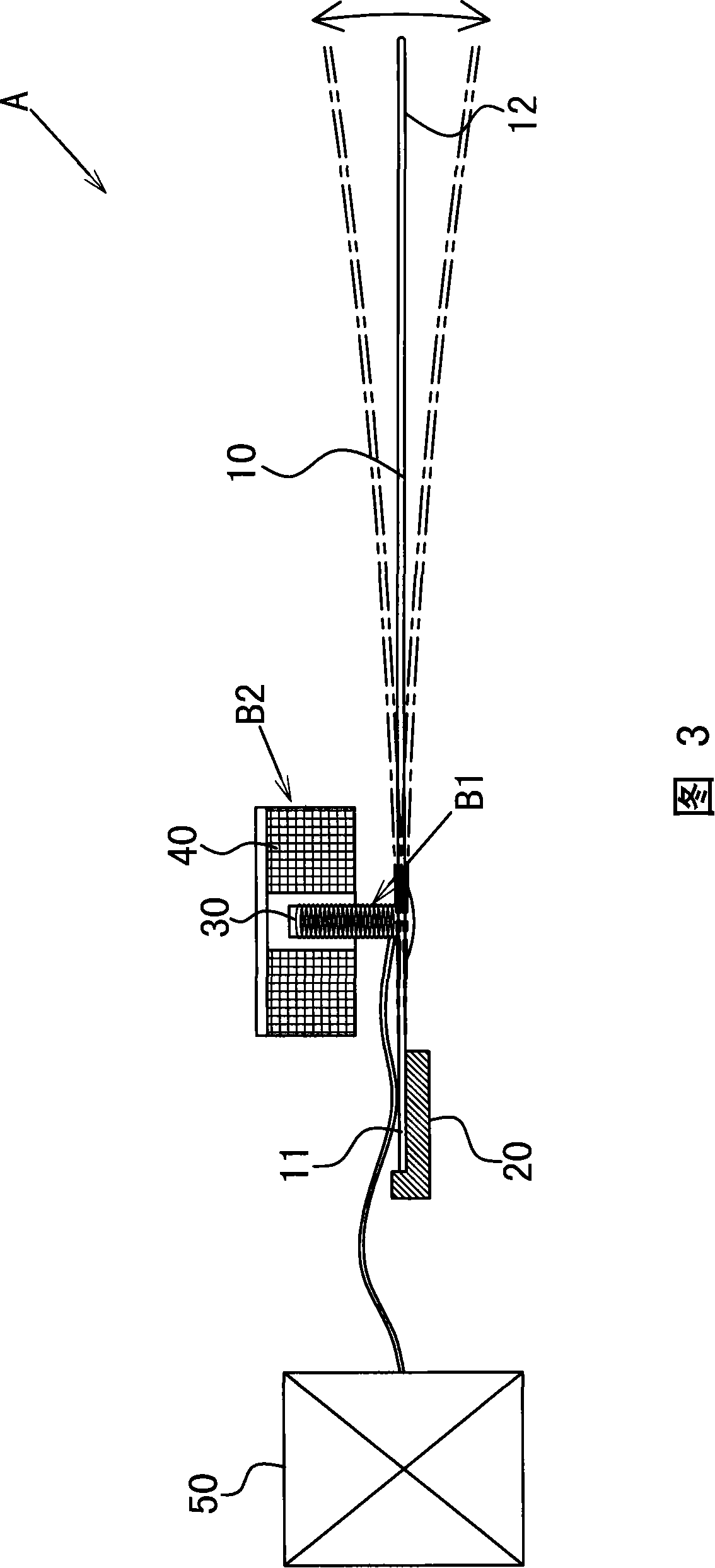

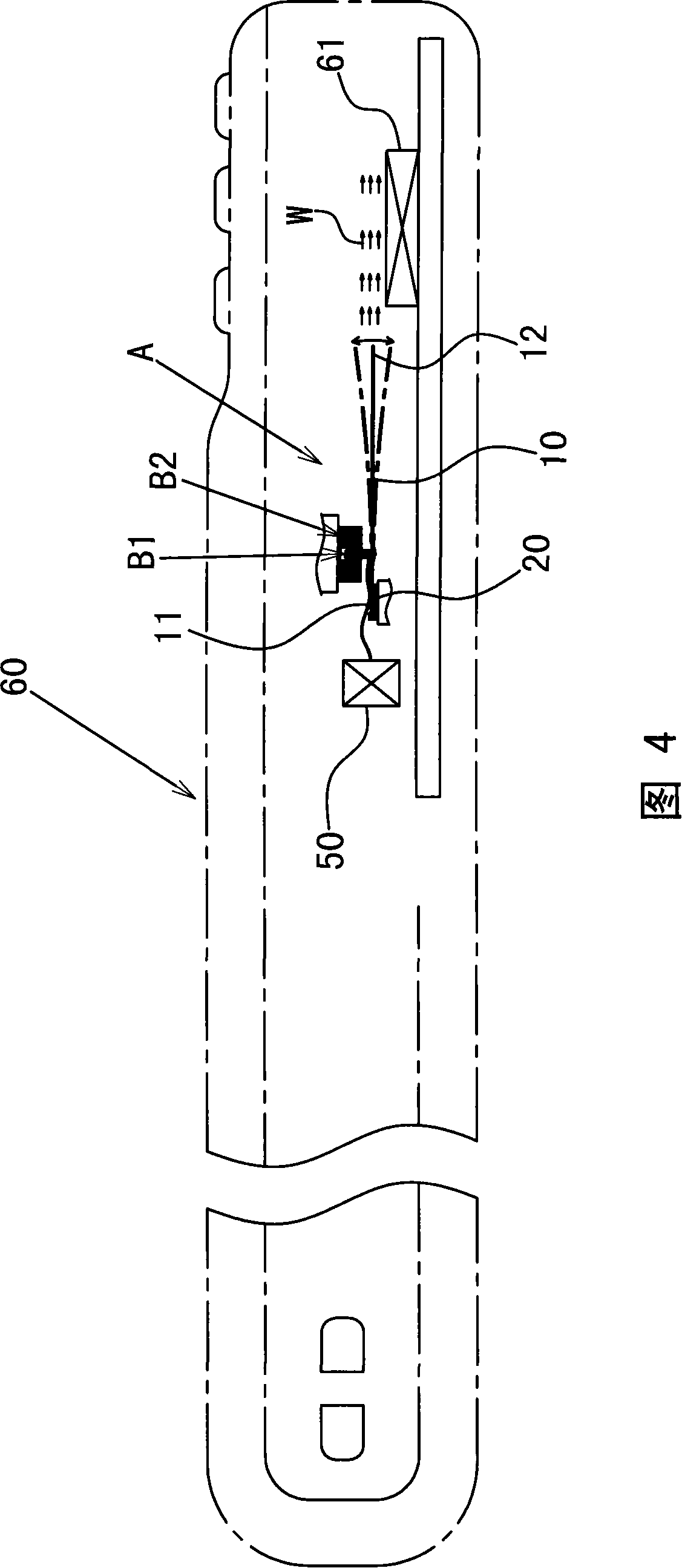

[0029] Please refer to Figures 1-2, which are preferred embodiments of the airflow generator of the present invention, the airflow generator A includes:

[0030] The sheet body 10 is in the shape of a long plate, including a support portion 11 and a swing end 12 away from the support portion 11;

[0031] The first magnetic induction part B1 is assembled at the position of the sheet body 10 close to the supporting part 11;

[0032] The second magnetic induction action part B2 is assembled at the corresponding interval of the first magnetic induction action part B1, so the magnetic induction state between the first and second magnetic induction action parts B1 and B2 can be used Changes, resulting in repeated changes of magnetic attraction and repulsion, and then can drive the swing end 12 of the sheet body 10 to swing.

[0033] Wherein, the support portion 11 of the sheet body 10 is combined with a fixed seat 20;

[0034] The support portion 11 and the fixing seat 20 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com