Flange fabrication method for hollow concrete pile

A technology of hollow concrete and flanges, which is applied in building construction, foundation structure engineering, sheet pile walls, etc., can solve problems such as complicated procedures and high manufacturing costs, and achieve the effect of preventing damage or breaking and strengthening rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] In the description of the present invention, the description shall be based on the drawings. The vertical direction is drawn based on the horizontal line of the drawing, the left-right direction is drawn based on the vertical line of the drawing, and the direction toward the center of the drawing is defined as the inner side, and the direction opposite to the inner side is defined as the outer side.

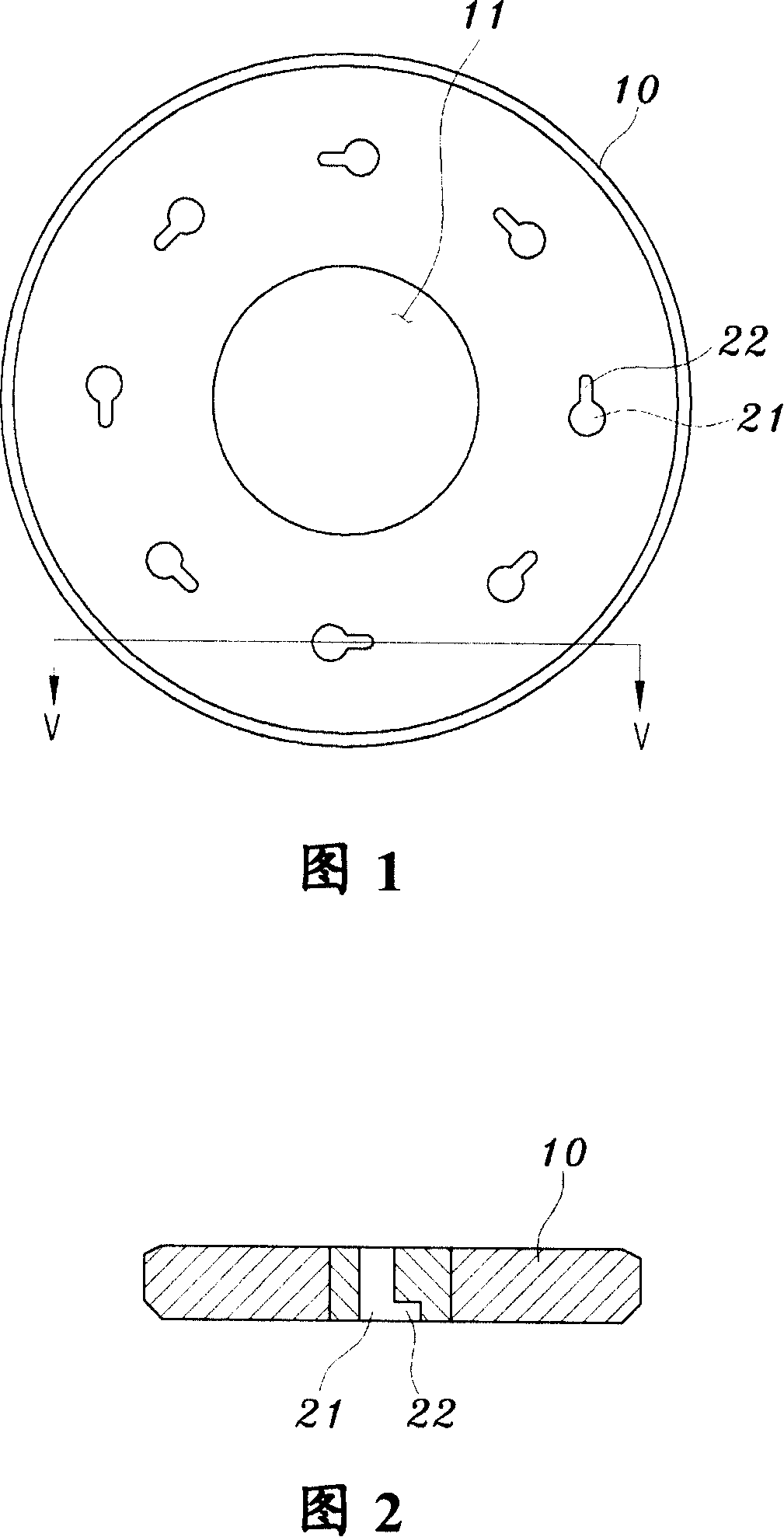

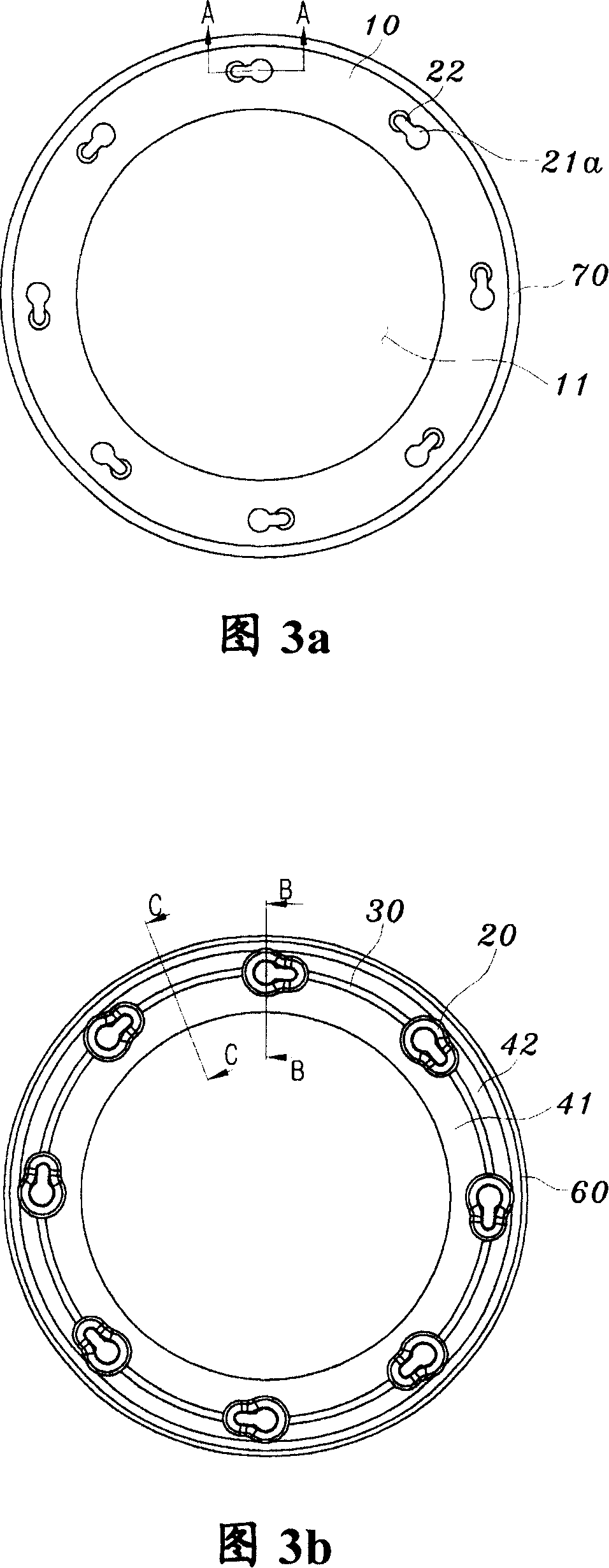

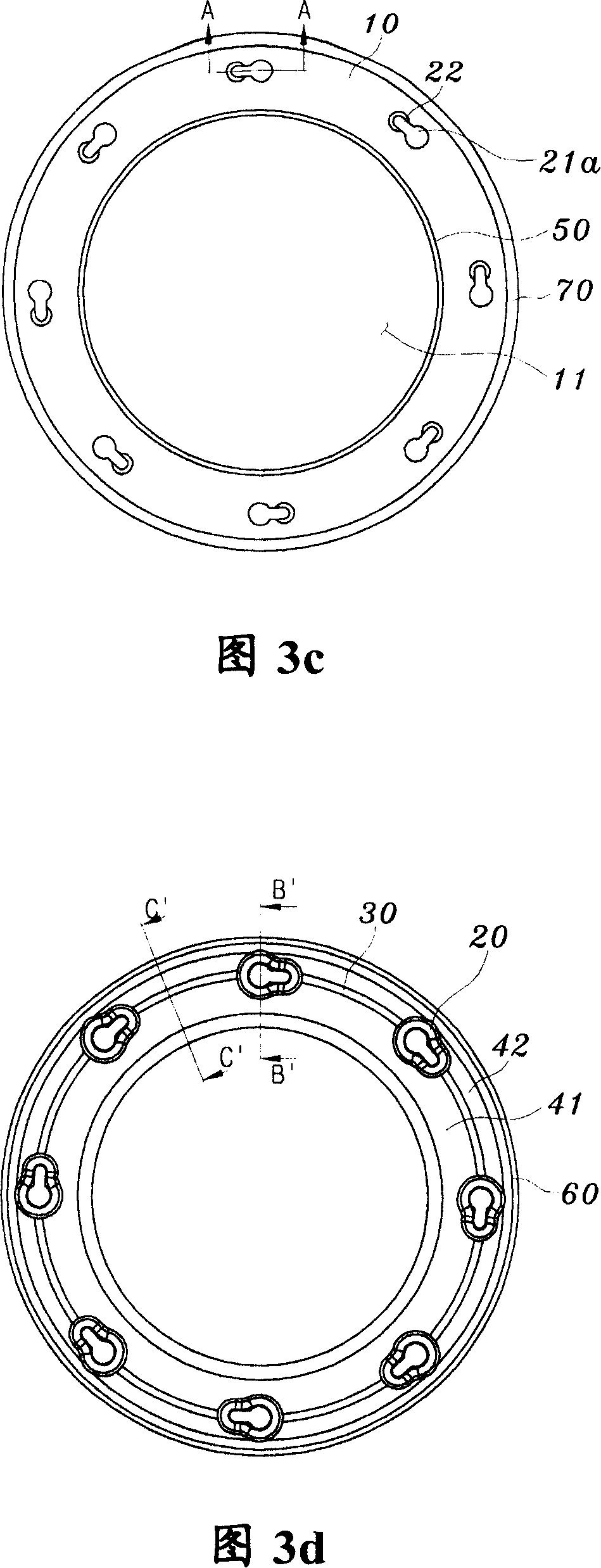

[0026] Fig. 3 a and Fig. 3 b are the two-sided structure diagrams of the flange concave structure used for the hollow concrete member according to the present invention, and Fig. 3 c and Fig. 3 d are the double-sided structure of the flange convex structure used for the hollow concrete member according to the present invention picture. Fig. 3a and Fig. 3c show the state diagram of the flange on the side not in contact with the concrete, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com