Elastic strip fixing machine

A technology of installation machine and installation mechanism, which is applied in the direction of laying tracks, roads, tracks, etc., can solve the problems of unable to meet the requirements of rapid installation, high labor intensity of workers, and low construction efficiency, and achieve the reduction of labor intensity of workers, simple structure and easy construction. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

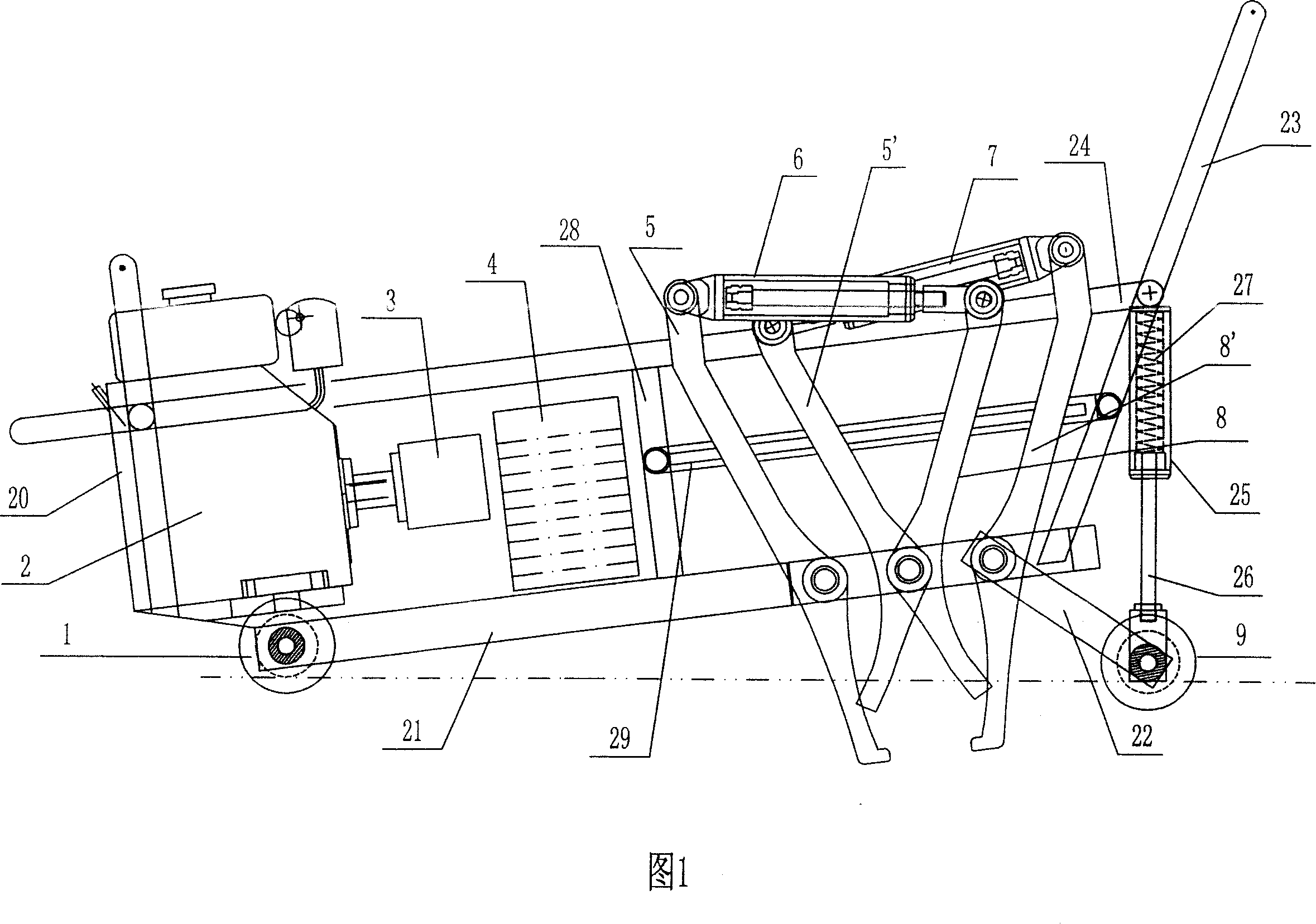

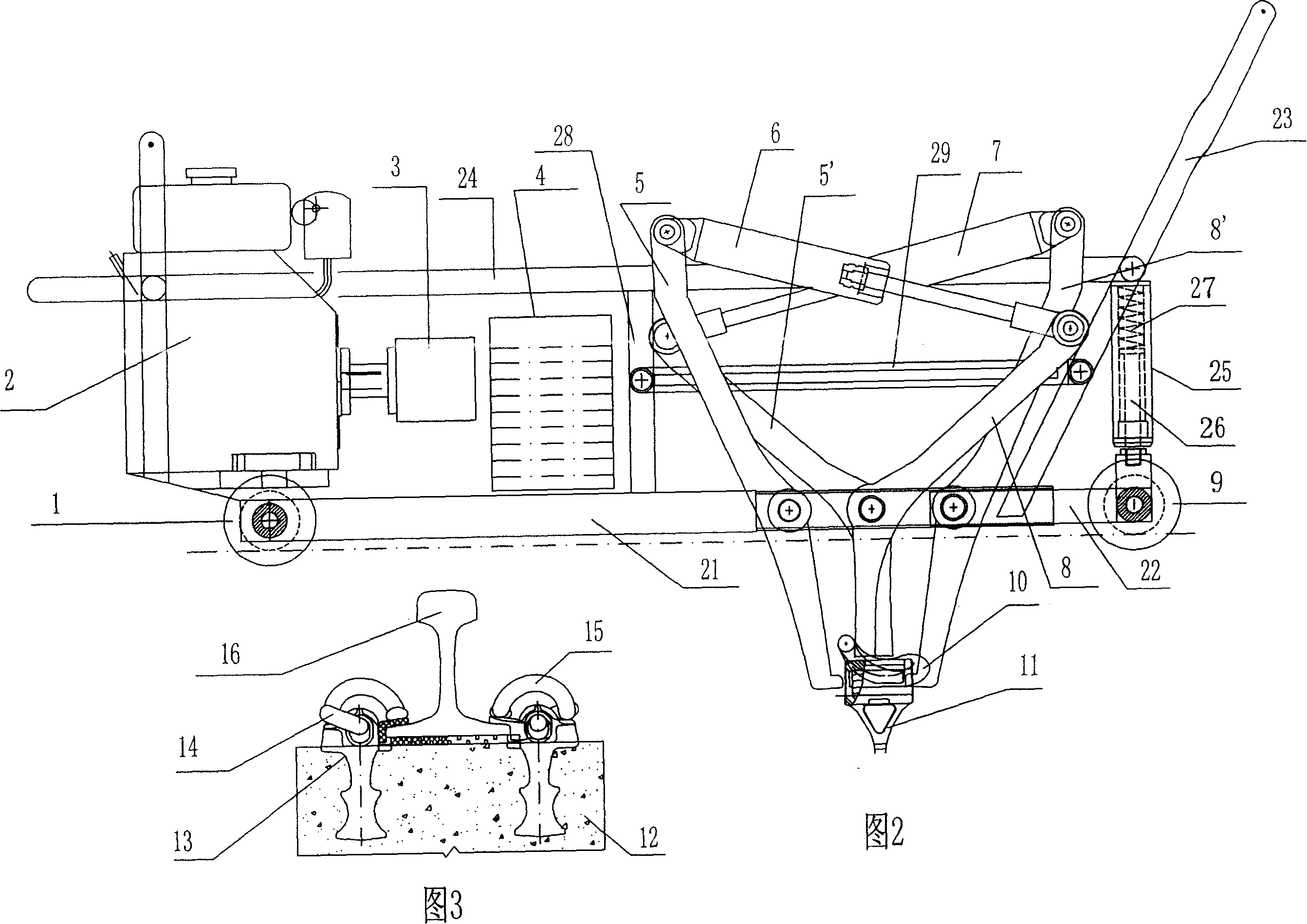

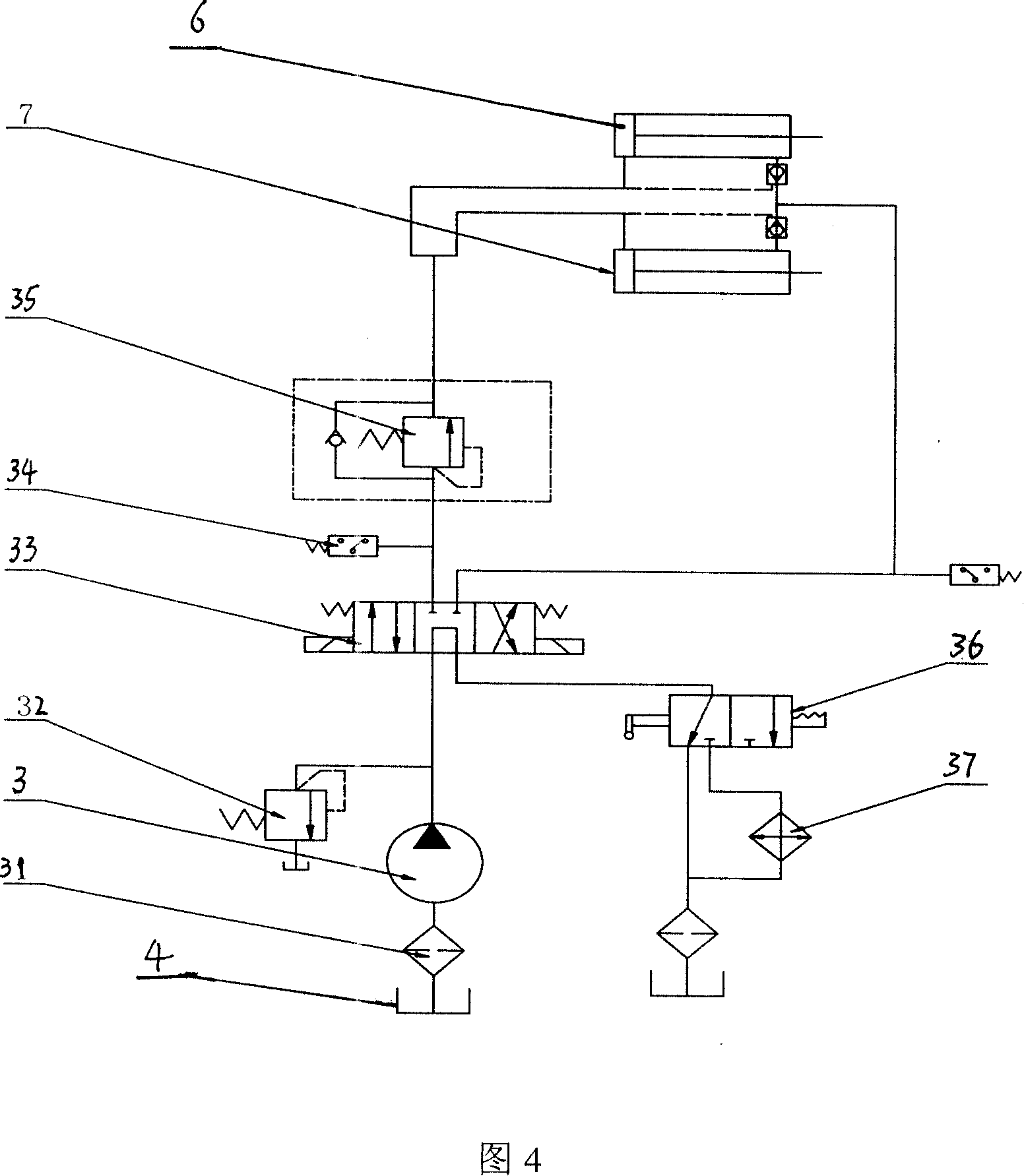

[0015] Elastic installation machine, comprising frame 20 with a traveling mechanism, three radial connecting holes are arranged at intervals on the lower frame 21 of the frame, and elastic installation mechanisms are arranged on both sides of the lower frame 21 of the frame, and the elastic installation mechanism includes an oil cylinder 6, 7 and the support arms 5, 5' and the outward crank arm shift forks 8, 8' which are respectively hinged with the bottom end of the oil cylinder and the top of the piston, the support arm 5 and the crank arm shift fork 8 of the left elastic strip installation mechanism pass through the front The two connection holes are hinged with the lower frame 21 of the frame, and the lever arm shift fork 8' and the support arm 5' of the right side spring bar installation mechanism are hinged with the lower frame 21 of the frame through the rear two connection holes in sequence. The lower ends of the support arms 5, 5' are horizontally bent towards the cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com