Liquid crystal display panel and method for producing same

A technology of liquid crystal display panel and display area, applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of low detection efficiency and high production cost of liquid crystal display panels, achieve simple and convenient detection operation, avoid waste of production capacity, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

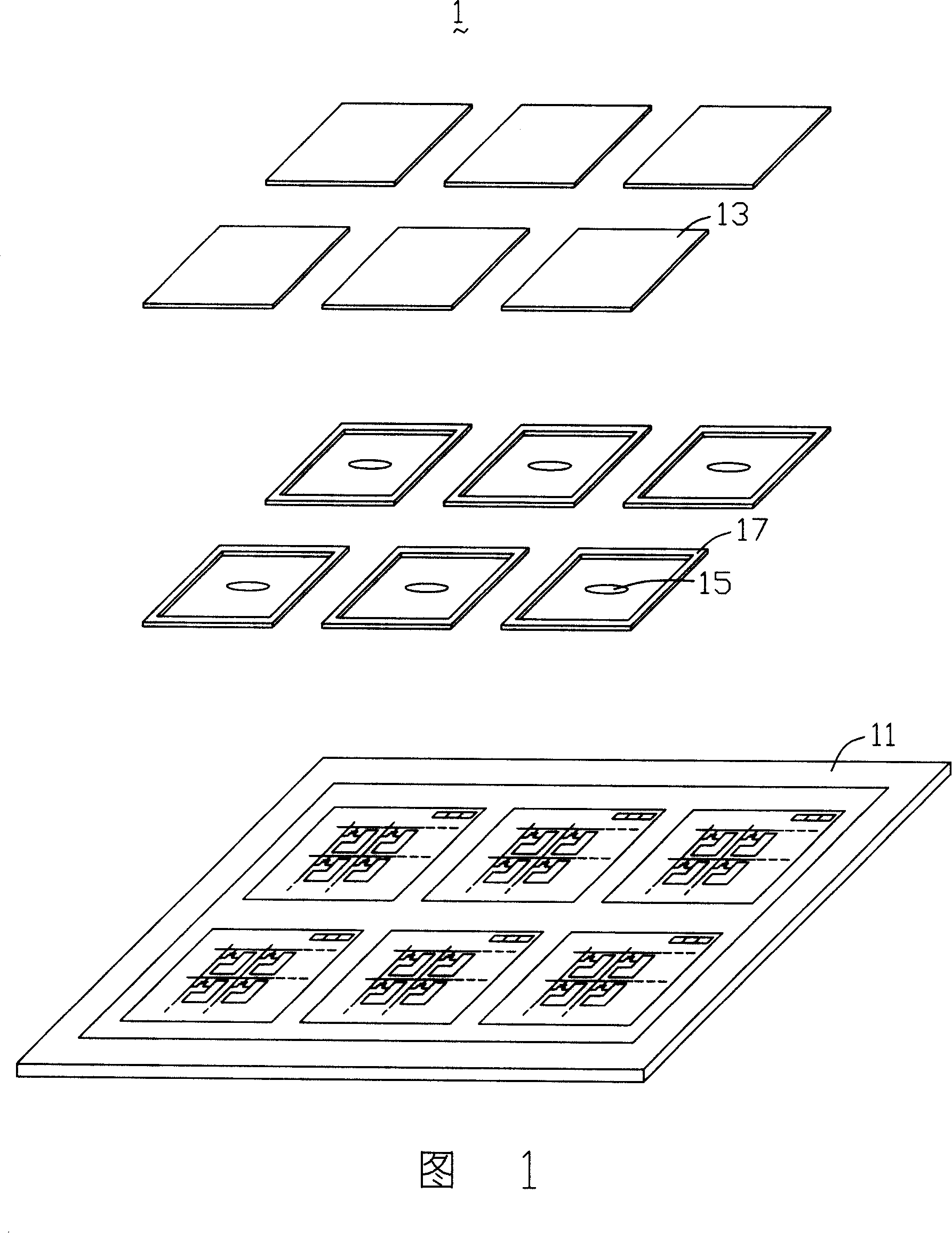

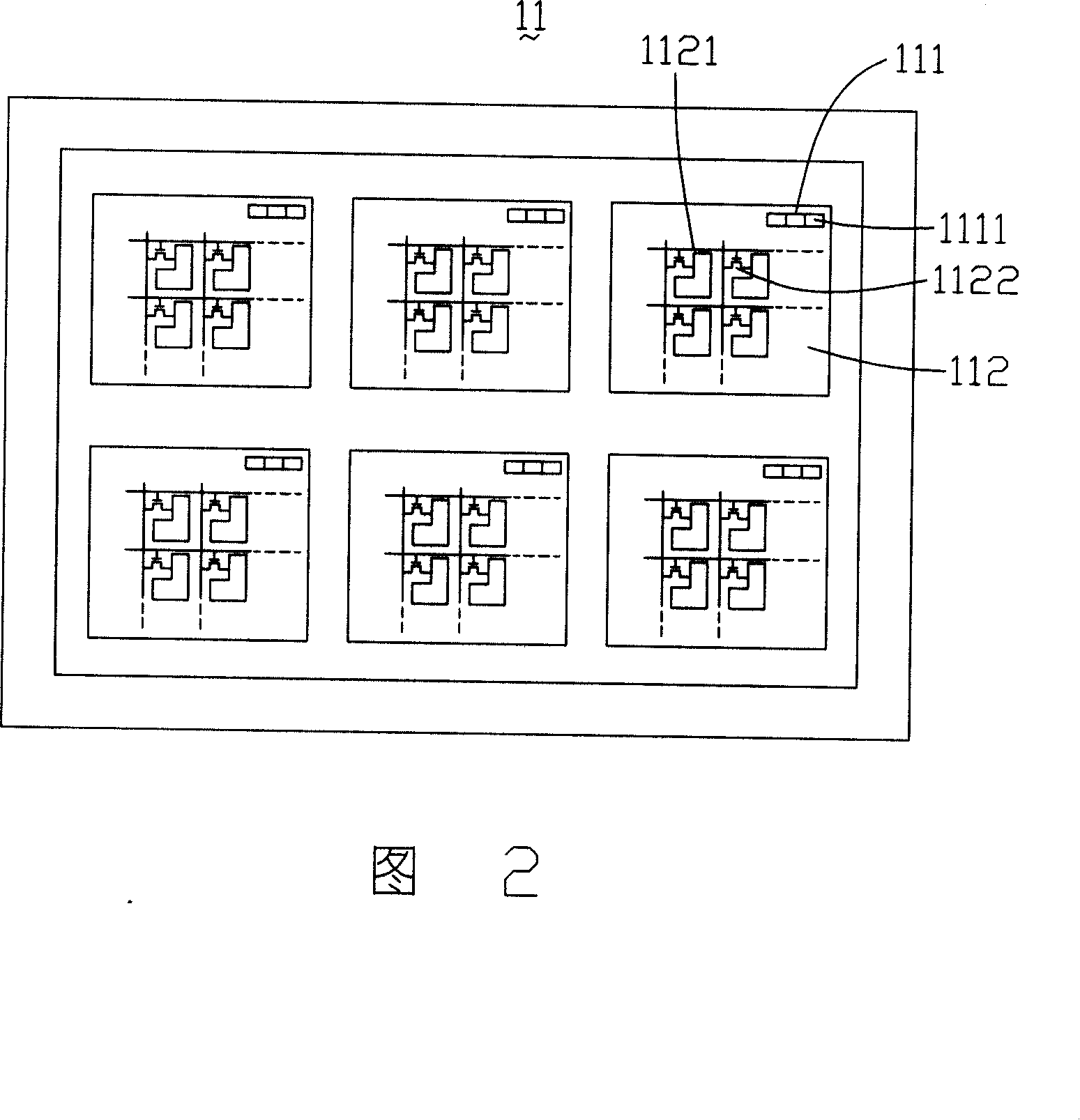

[0027] Please refer to FIG. 3 , which is an exploded perspective view of a liquid crystal display panel disclosed in a preferred embodiment. The liquid crystal display panel 2 includes a thin film transistor substrate 21 , a plurality of color filter substrates 23 , a plurality of liquid crystal layers 25 and a plurality of sealants 27 . The thin film transistor substrate 21 and each color filter substrate 23 are arranged at intervals relative to each other, and the plurality of liquid crystal layers 25 and the plurality of sealants 27 are sandwiched between the thin film transistor substrate 21 and the plurality of color filter substrates. 23 rooms. And each color filter substrate 23 corresponds to a liquid crystal layer 25 and a frame glue 27 respectively.

[0028] The color filter substrate 23 is used to make the liquid crystal display panel 2 present color images.

[0029] The liquid crystal layer 25 is an organic layer that acts on the liquid crystal material through an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com