Anti-block device for horizontal centrifugal machine feeding tube

A technology for decanter centrifuges and feed pipes, applied to centrifuges, centrifuges with rotating drums, etc., can solve problems affecting the normal service life of centrifuges, achieve no jamming, eliminate jamming, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

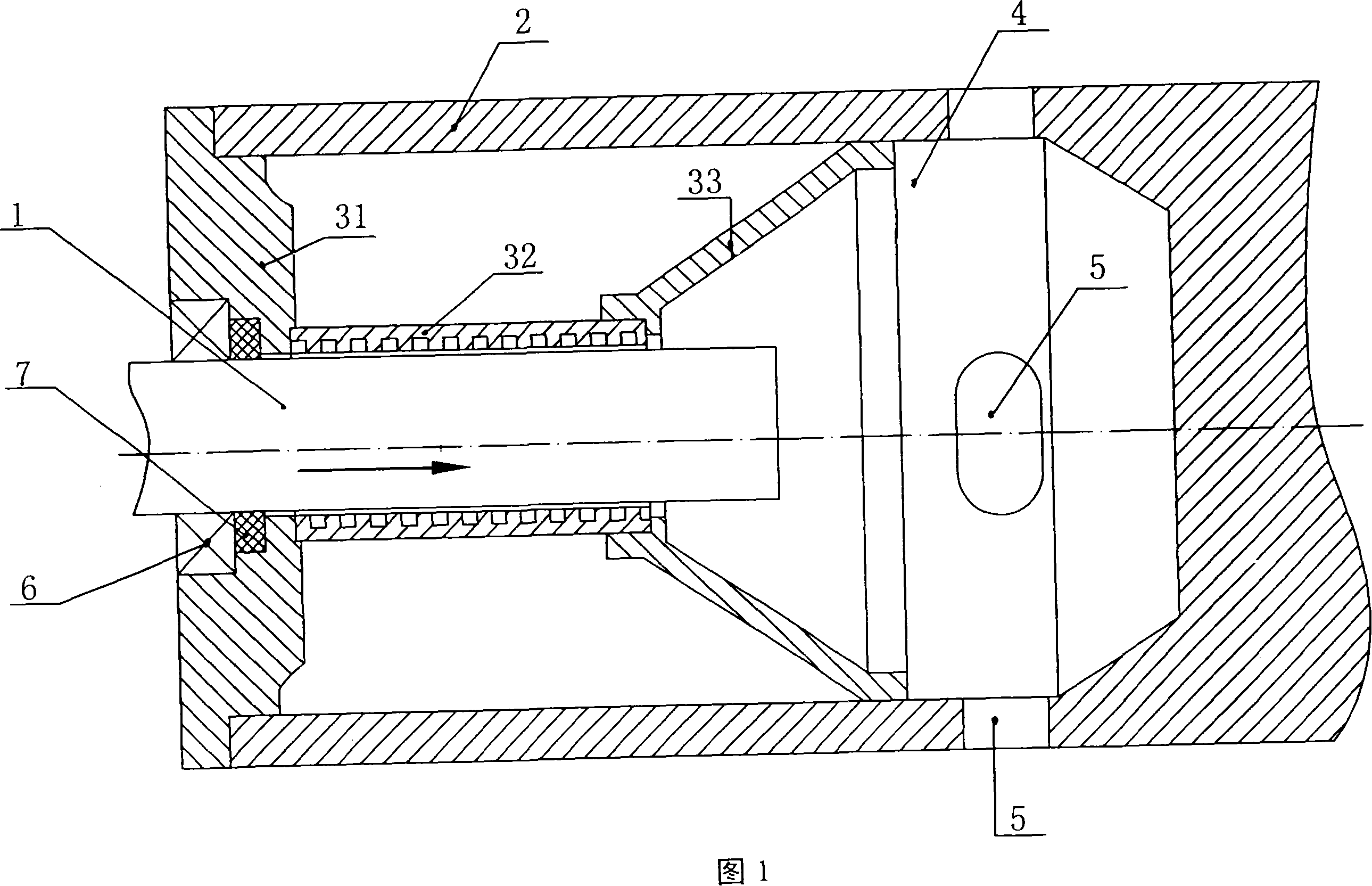

[0012] Embodiment 1: As shown in accompanying drawing 1, the feed pipe anti-jamming device of described decanter centrifuge comprises feed pipe 1, screw feeder and frame, and screw feeder is composed of main shaft 2 and screw pusher. Composed of pressing tablets, the feeding end of the main shaft 2 is provided with a shaft hole for easy installation of the feeding pipe 1, and the outer surface of the main shaft 2 is distributed with the lead of the screw pushing the pressing piece, and the main shaft 2 is fixed on the frame through two bearing seats. On the top, the feed pipe 1 is fixed on the frame, and the feed pipe 1 is installed in the inner hole of the feed end of the main shaft 2 through the anti-blocking sleeve 3. The anti-blocking sleeve 3 consists of a left end cover 31, a threaded sleeve 32, a horn sleeve 33, the horn sleeve 33 is fixed on the right end of the threaded sleeve 32, the left end cover 31 is fixed on the left end of the threaded sleeve 32, and a bearing 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com