Display device and manufacturing method thereof

一种显示装置、制造方法的技术,应用在静态指示器、光学、仪器等方向,能够解决不能防止短路环静电破坏静电破坏等问题,达到降低不良产品的发生率、大型化提高、显示质量提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, best embodiments of the present invention will be described with reference to the accompanying drawings.

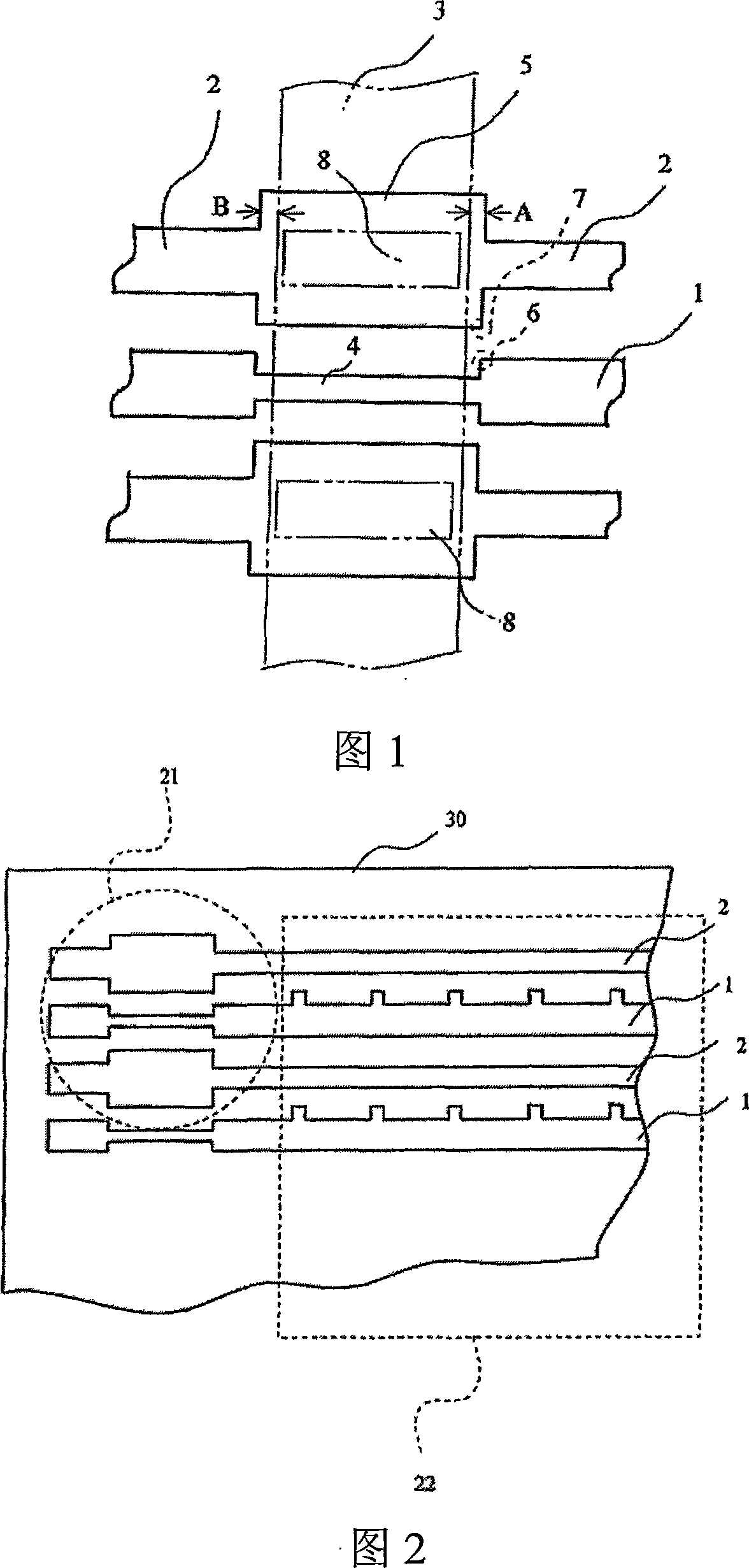

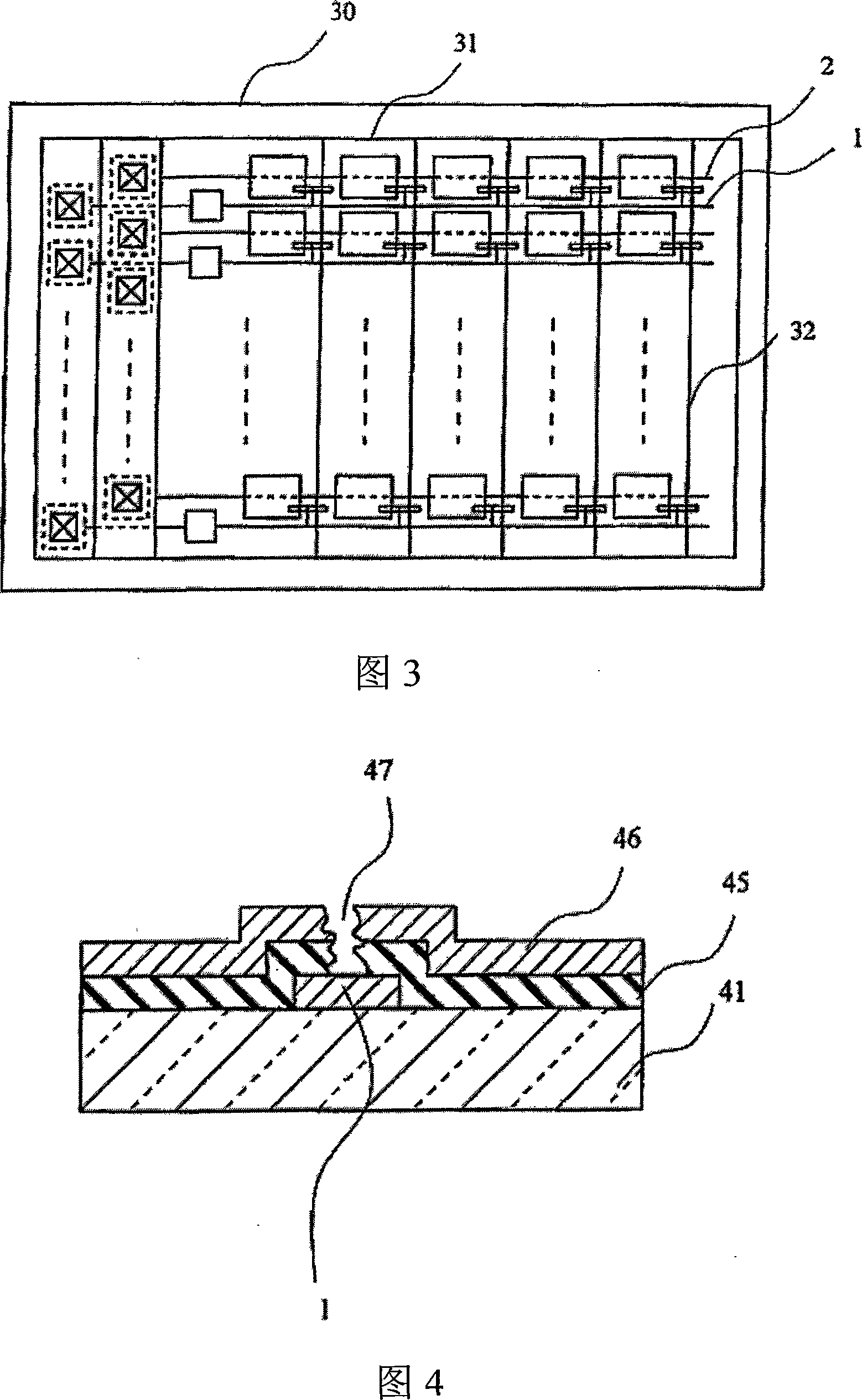

[0054]FIG. 1 is a schematic plan view illustrating a part of a TFT array substrate of a display device according to an embodiment of the present invention. FIG. 2 is a partial explanatory view of the TFT array substrate showing the positions of the parts involved in FIG. 1 on the TFT array substrate. In FIG. 1, 1 is a scanning line, 2 is an auxiliary capacitor line, 3 is an auxiliary capacitor line voltage supply line for supplying voltage to the auxiliary capacitor line, 4 is a rectangular part of the scanning line, 5 is a rectangular part of the auxiliary capacitor line, and 6 7 is the rectangular corner of the scanning line, 7 is the rectangular corner of the auxiliary capacitor line, 8 is a through hole, A is the length of the right end of the rectangular part 5 of the auxiliary capacitor line beyond the line width of the auxiliary capacitor line v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com