Opposite-clamping pore plate flow quantity adjusting valve

An orifice flow and valve technology, used in sliding valves, valve devices, engine components, etc., can solve problems such as poor flow accuracy control and inability to accurately control high-speed flow, achieve precise adjustment, reduce vibration, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

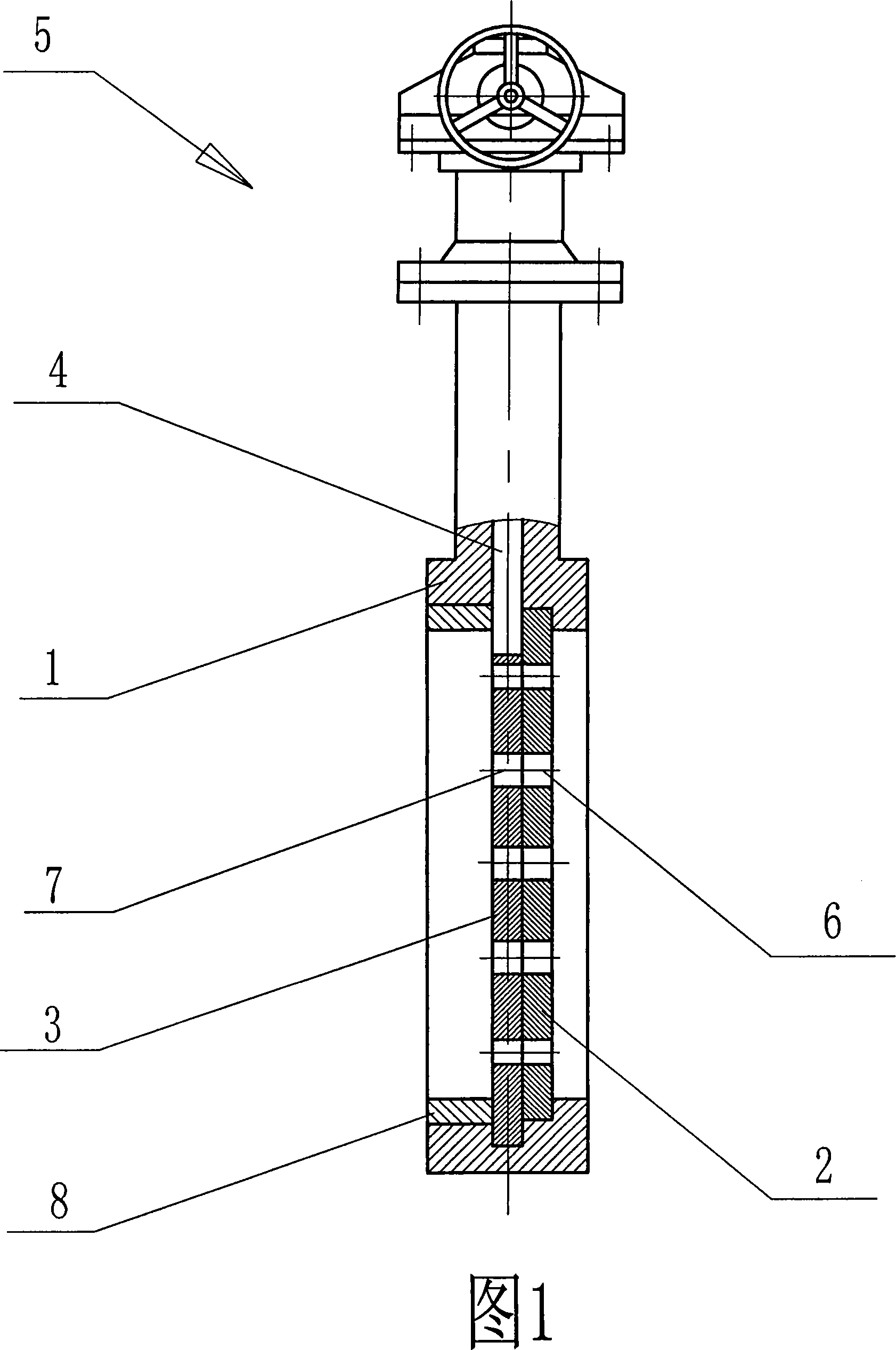

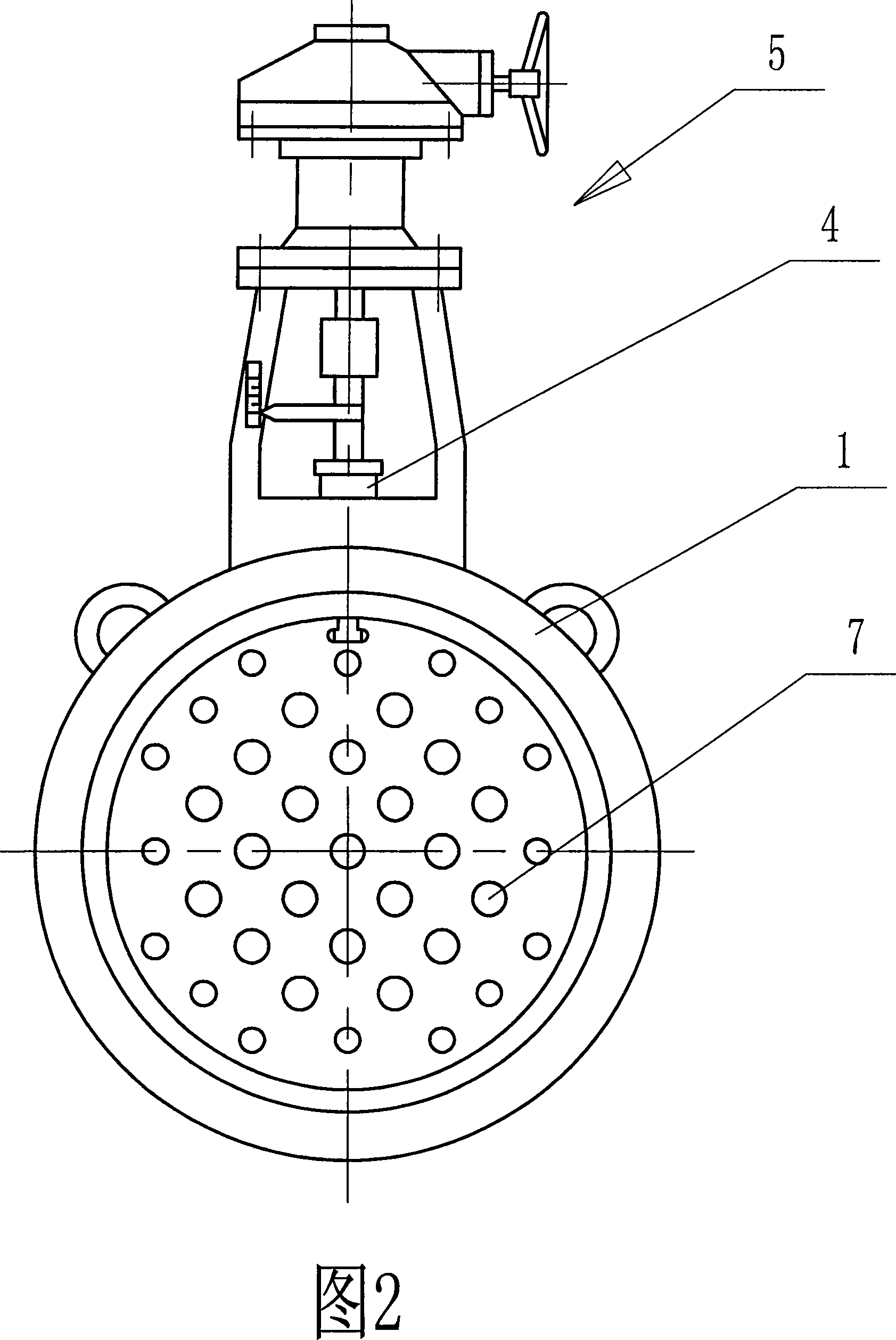

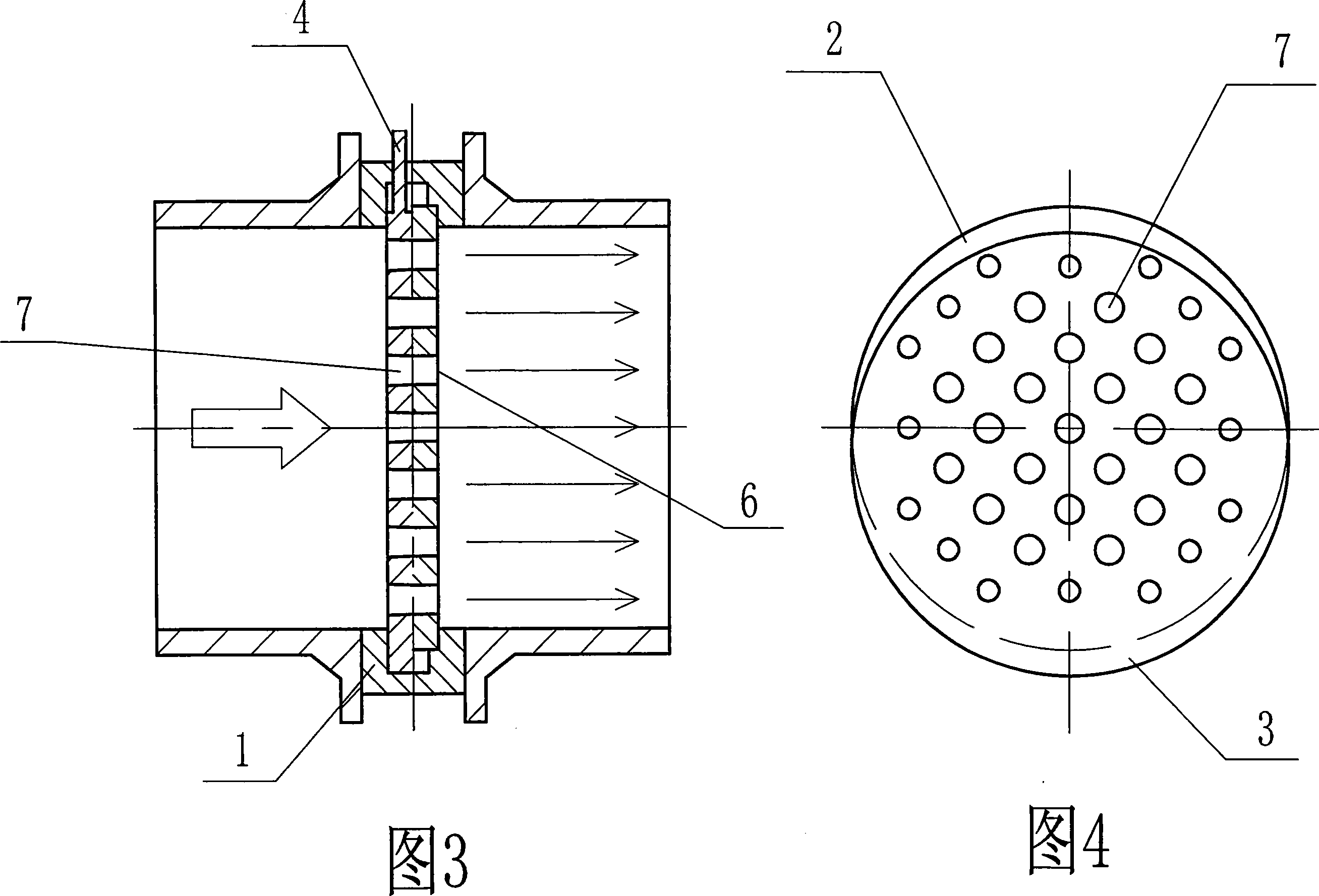

[0024] See Figure 1 and Figure 2. The wafer type orifice flow regulating valve of the present invention includes a valve body 1 , a fixed valve plate 2 , a movable valve plate 3 and an operating mechanism 5 . Wherein the fixed valve plate 2 is fixedly installed in the valve body 1, and the movable valve plate 3 is installed in the valve body 1 so as to move up and down. The movable valve plate 3 is in contact with the fixed valve plate 2. The movable valve plate 3 is provided with a valve stem 4, and the valve stem 4 extends out of the valve body and is connected with the operating mechanism 5. On the side of the movable valve plate 3 close to the inlet, there is a retaining ring 8 for sealing.

[0025] Described operating mechanism 5 can select any existing structure for use, as hydraulic pressure type, pneumatic type, mechanical t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com