Device for transferring non-standard track space engine on the standard track space circuitry

A technology of non-standard gauge and standard gauge, which is applied in the directions of transportation and packaging, railway car body parts, turntable/moving platform, etc., which can solve the problems of inability to transfer the whole vehicle and high cost, and is beneficial to side push operation , anti-rolling, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

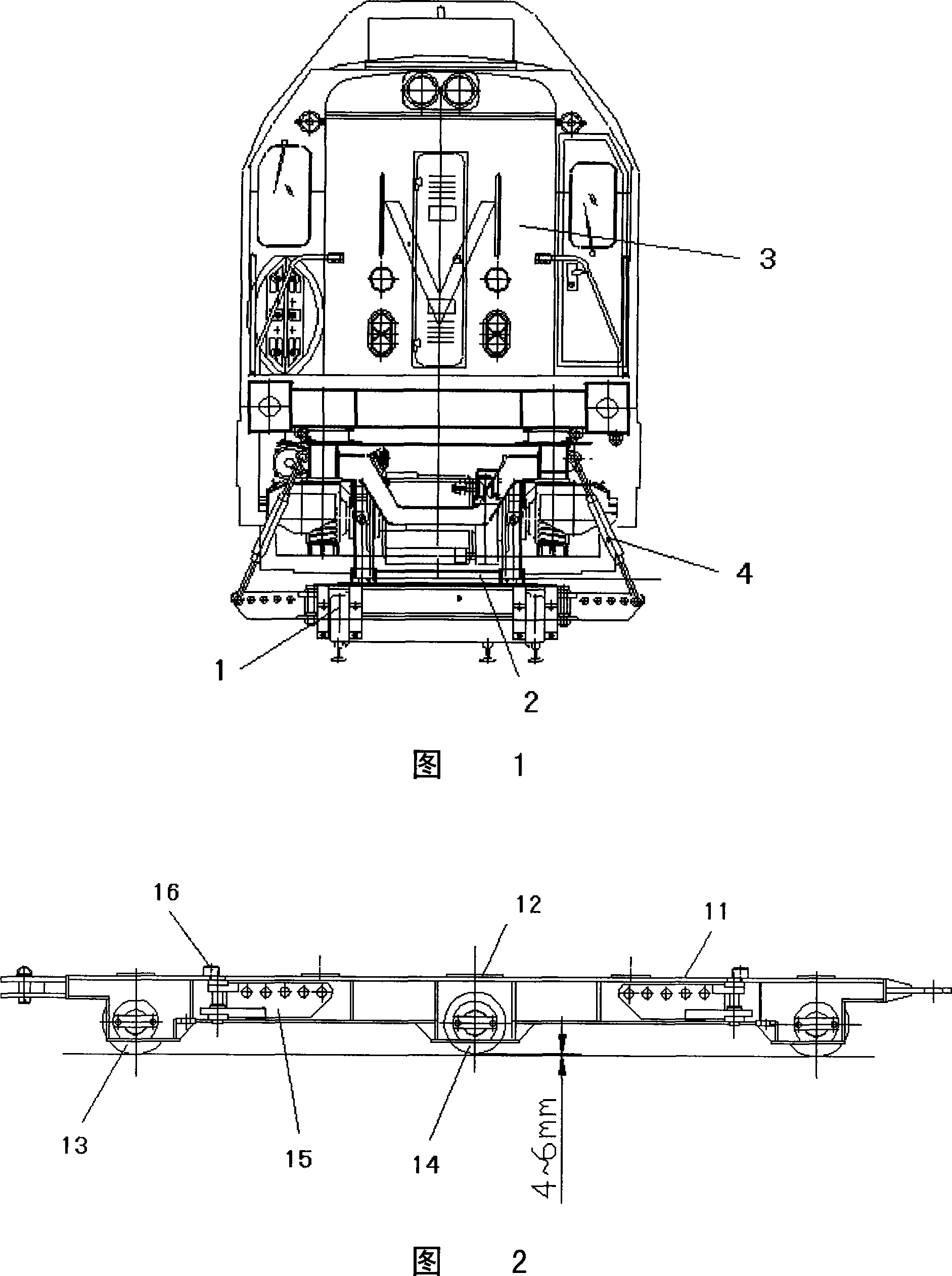

[0029] As shown in Fig. 1, the present invention includes a transfer trolley 1 arranged on the track and a bracket 2 connected to the transfer trolley 1, the locomotive 3 to be operated is arranged on the bracket 2, and a plurality of turnbuckle bolts 4 Connect with transfer trolley 1.

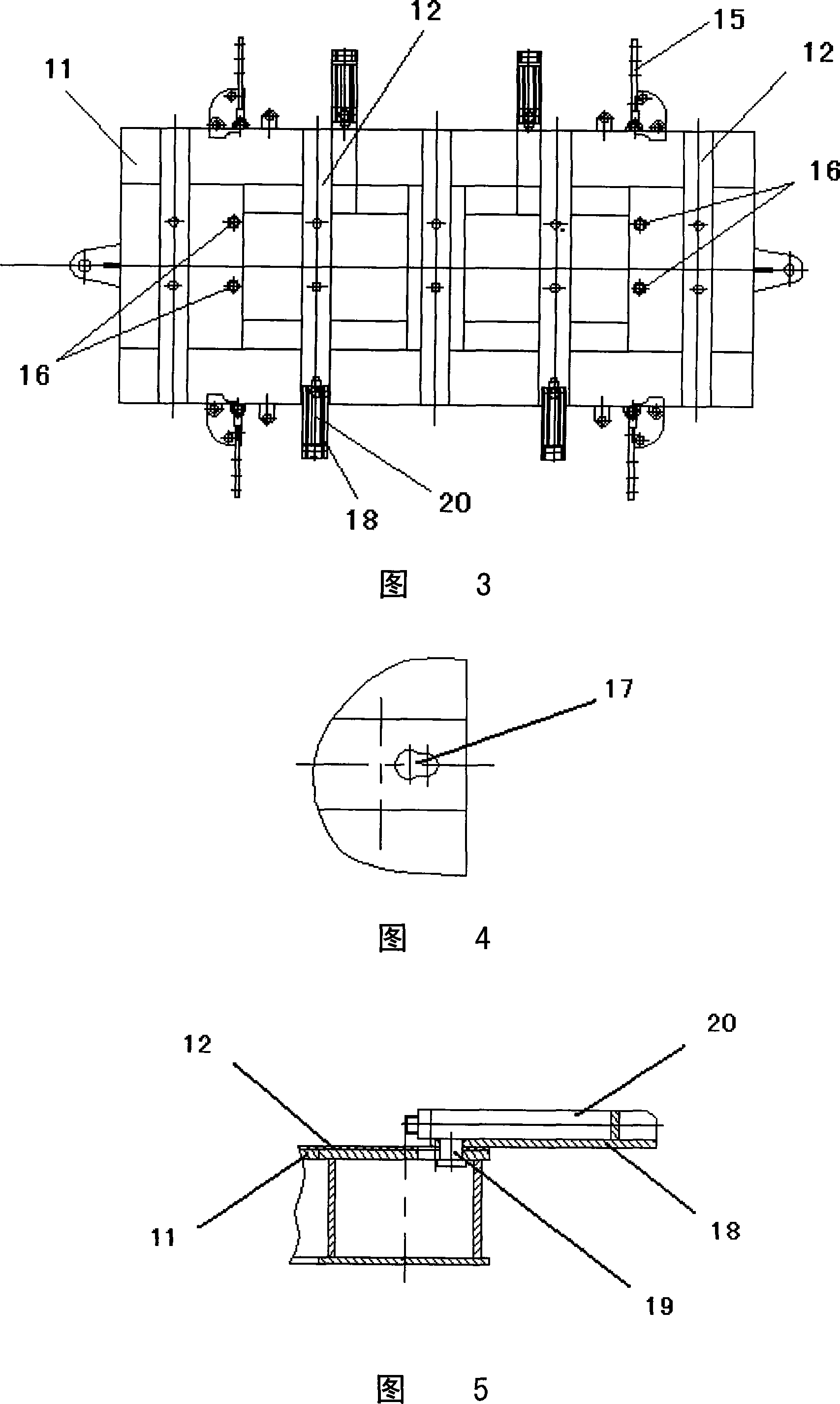

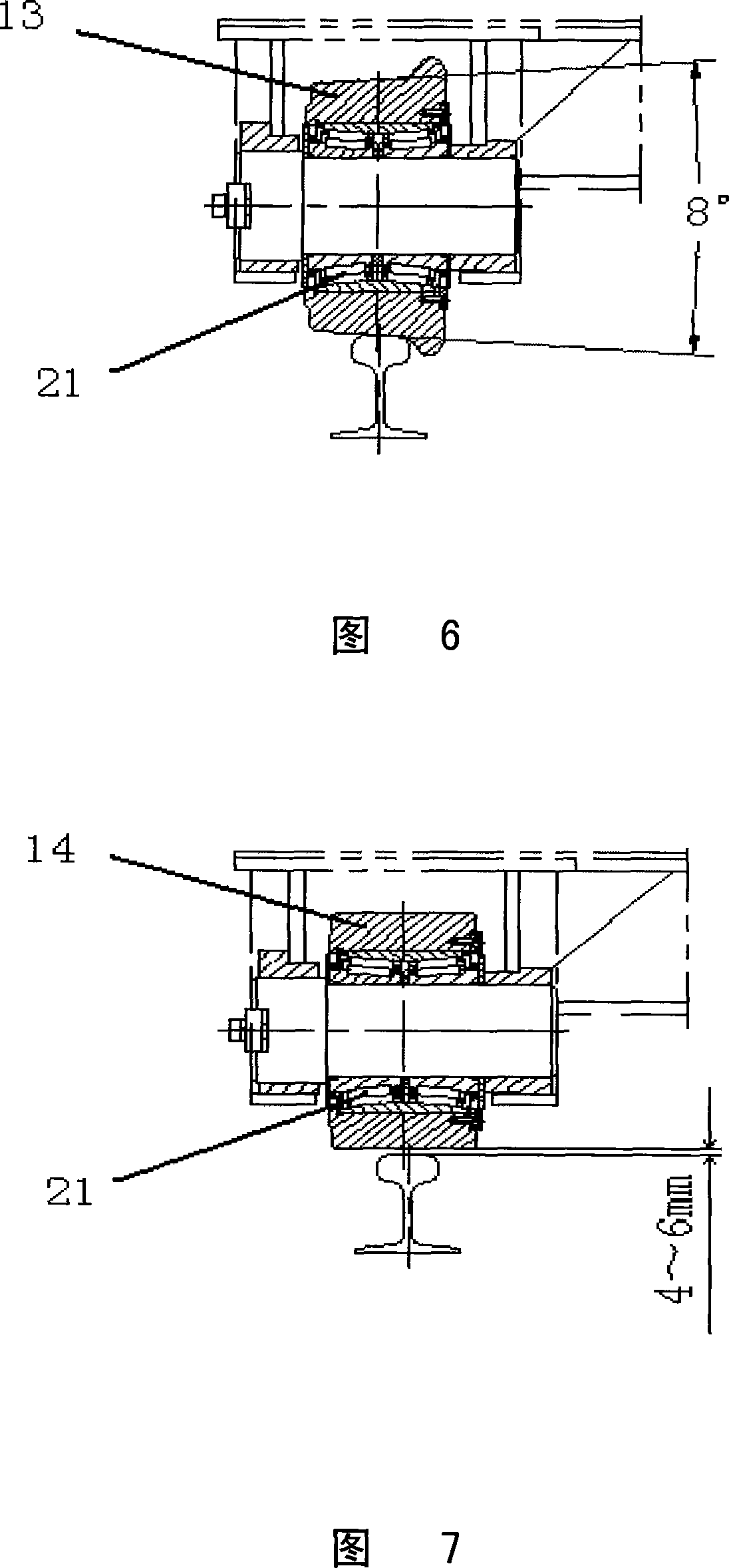

[0030] As shown in FIG. 2 , FIG. 3 , and FIG. 4 , the transfer trolley 1 of the present invention includes a platform 11 , support bars 12 , four-corner wheels 13 , middle wheels 14 and reinforcement plates 15 . The main body of the table top 11 is a large flat plate structure, 3 to 5 support bars 12 are welded on the table top 1, and the bracket 2 is placed on the support bars 12 to reduce the contact area between the table top 11 and the bracket 2, thereby reducing the The frictional force when the transfer locomotive 3 needs to be pushed sideways. The table top 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com