Differential thermomagnetic switch

A switch and thermomagnetic technology, applied in the direction of switches with electric heating and electromagnetic release, protection switches, circuit breaker contacts, etc., can solve the problems of high manufacturing and assembly costs, complex switches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

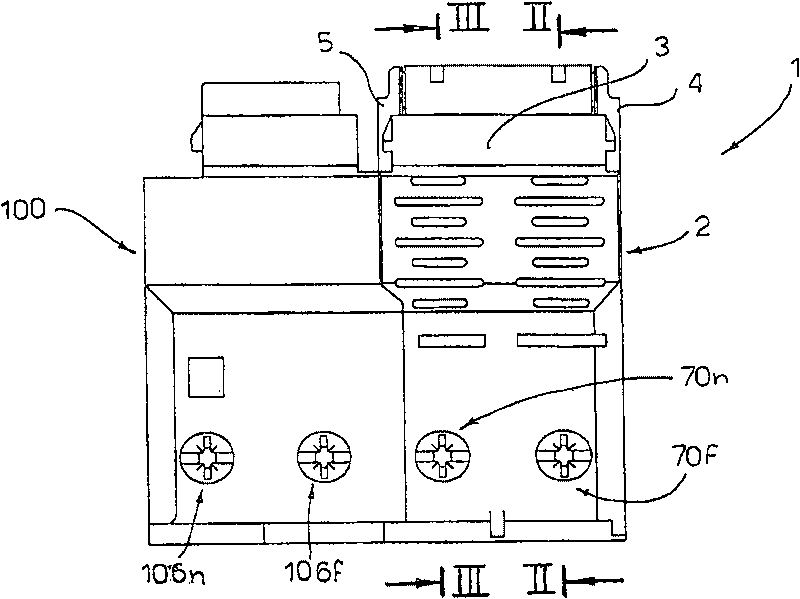

[0029] figure 1 A complete form of the differential thermomagnetic switch according to the invention is shown, which is designated as a whole by the reference numeral 1 .

[0030] The switch 1 has two box-like components next to each other: a thermomagnetic switch component 2 and a differential circuit component 100 .

[0031] The thermomagnetic switch unit 2 comprises a double-sided intermediate wall 3 which defines and separates two opposing housings 3f and 3n:

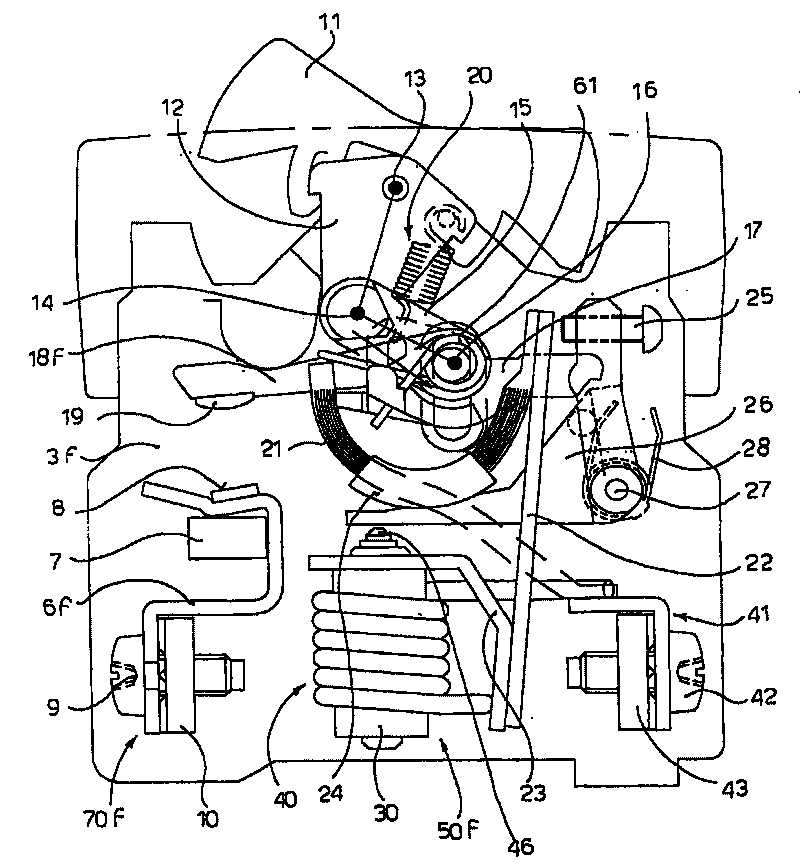

[0032] - the first housing 3f ( figure 2 ), which is called a phase housing since it houses the fixed contacts 6f connected to the phase line (supply line) of the electrical system, and

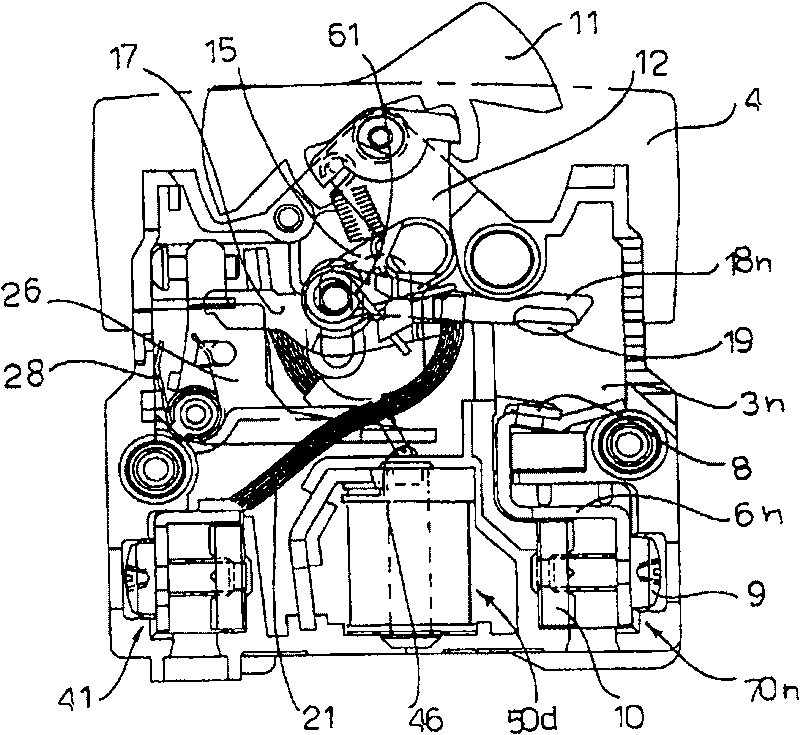

[0033] - the second housing 3n ( image 3 ), because it houses the fixed contact 6n connected to the neutral wire (ground wire) of the electronic system, it is called the neutral housing.

[0034] back to figure 1 , said housings 3f and 3n are covered by removable covers 4 and 5, respectively.

[0035] In the following, spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com