Laser marker for fully automatic IC material bar

A laser marking machine, fully automatic technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high labor intensity of workers and low marking quality, and achieve the goal of reducing labor intensity and ensuring accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

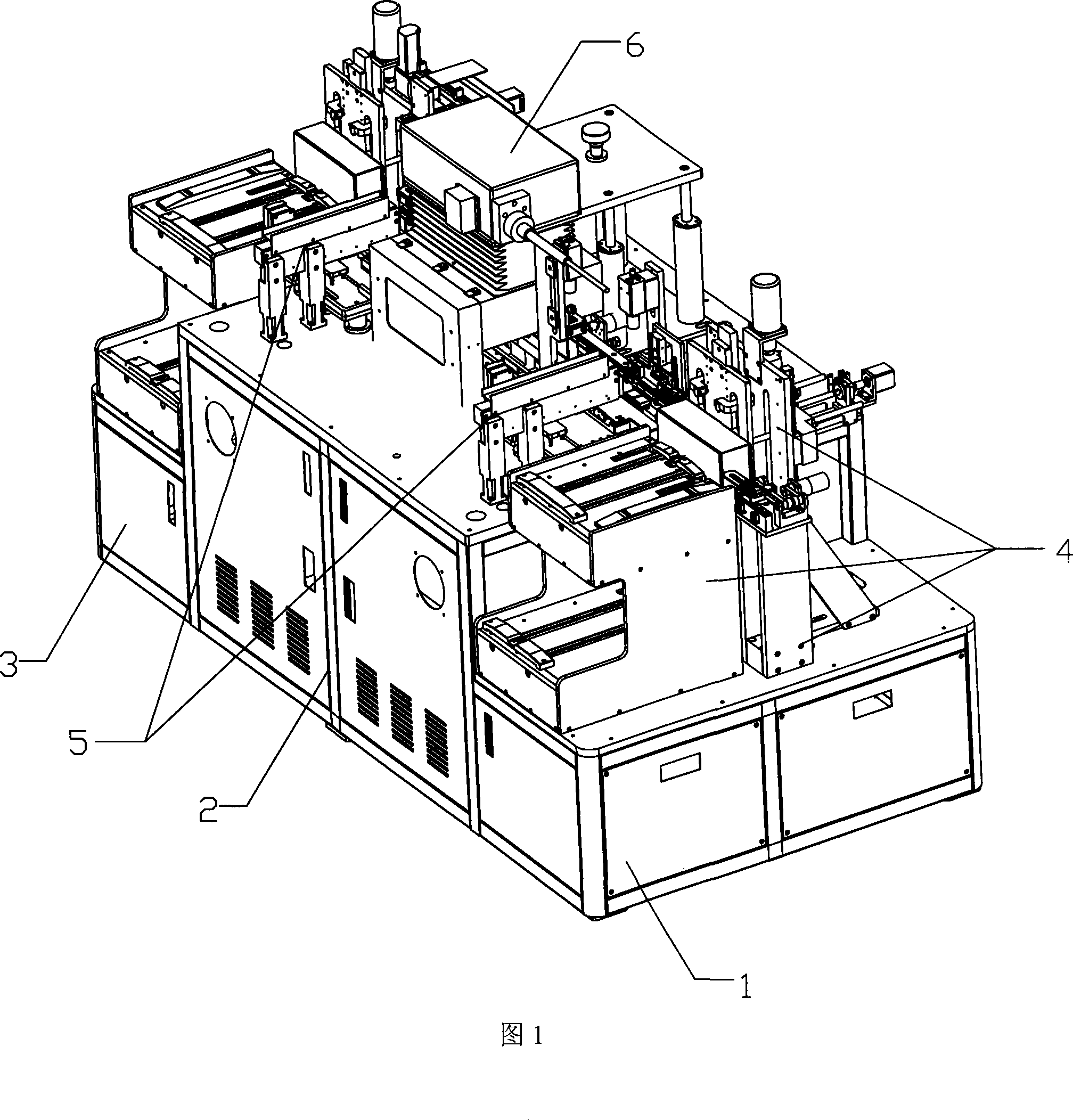

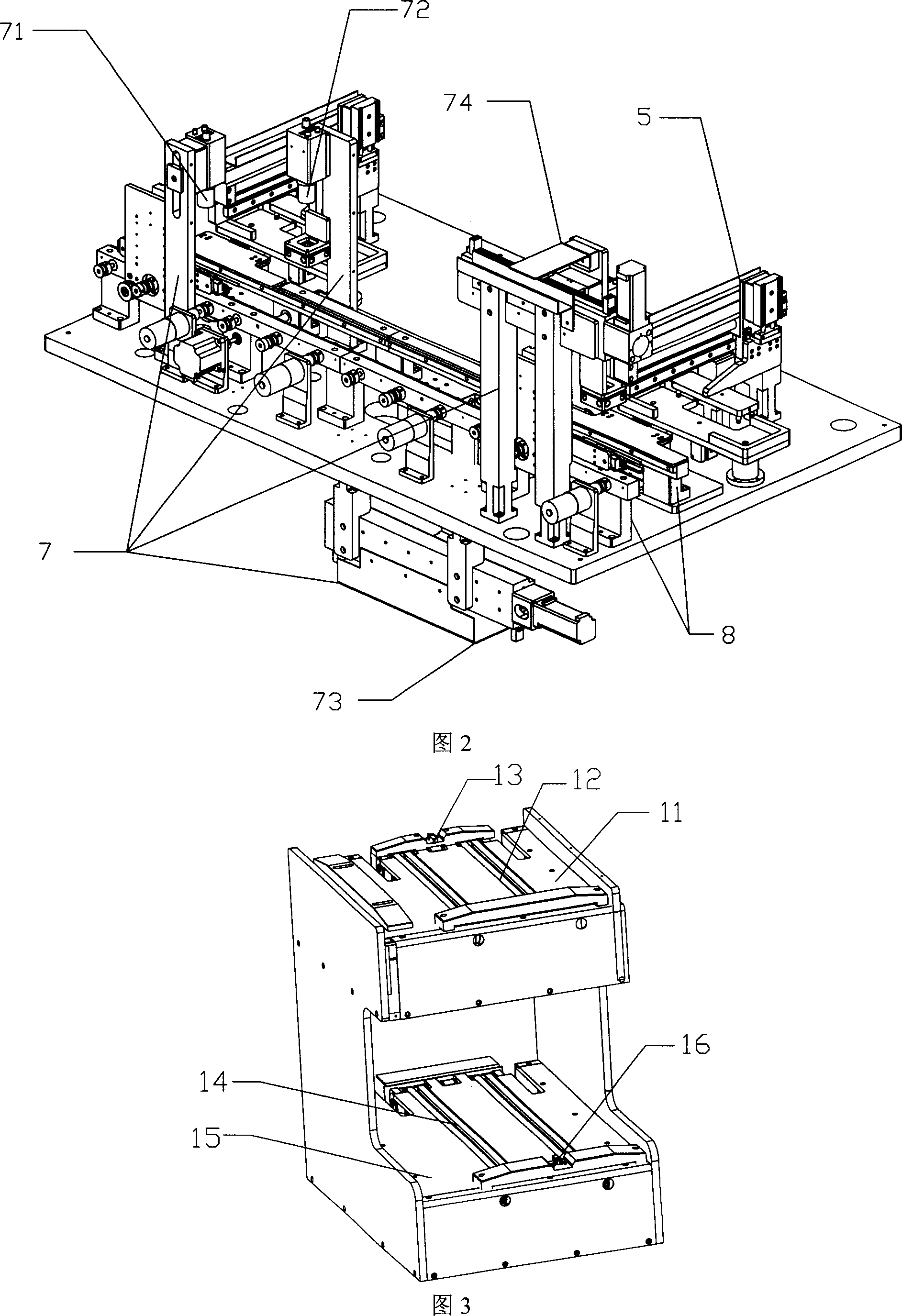

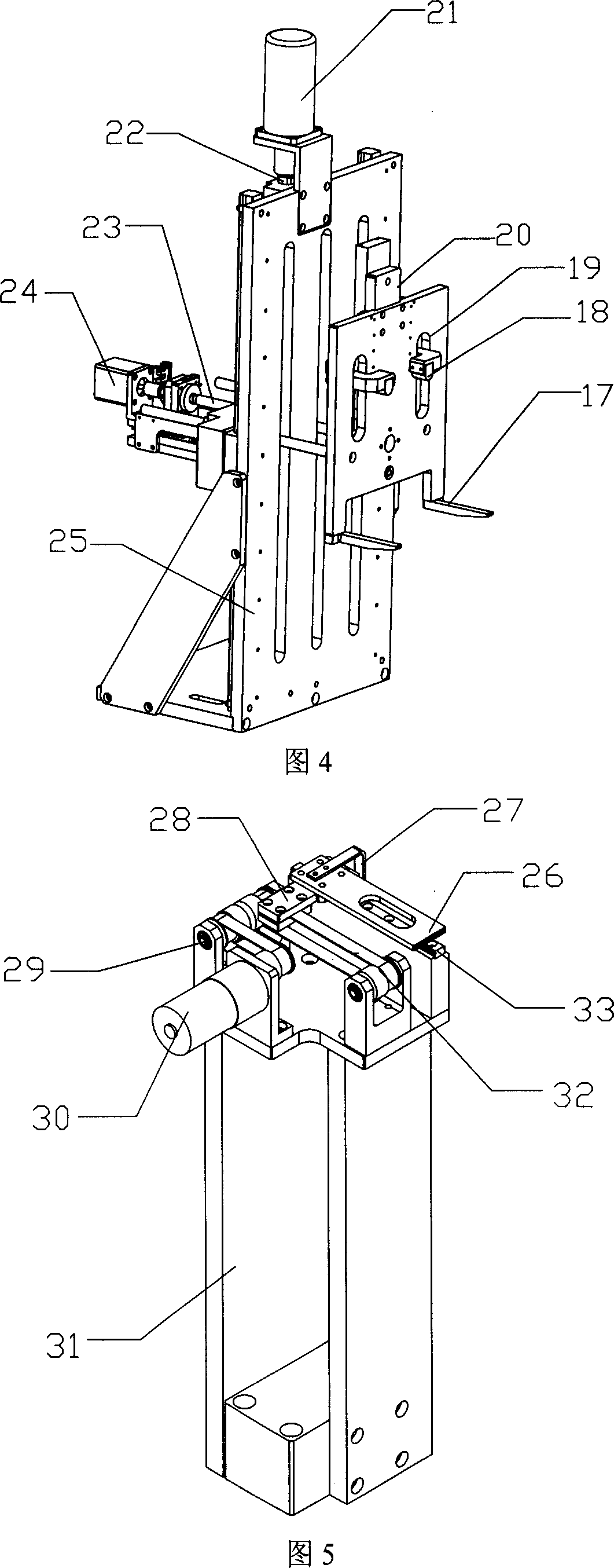

[0025] As shown in Figures 1 to 11, a specific embodiment of the present invention, a fully automatic IC bar laser marking machine, includes a body 1, a PC device 3 and an electric control system 2 are arranged inside the body, and the body 1 is provided with Controlled by the PC device 3, the loading and unloading device 4, the strip conveying device 8, the laser marking device 6, the detection system 7, and the rejecting device 5 are five major parts. The detection system 7 includes a direction detection device 71 and a batch number detection device 72. , marking position detection device 73 and post-mark quality detection device 74; The two ends of body 1 are respectively provided with loading and unloading box device 4 and unloading and boxing device, between two devices, be provided with material bar conveying device 8, between material bar The conveying lines on both sides of the conveying device 8 are successively provided with a direction detecting device 71, a batch nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com