Electromagnetic sealing device of axis for machine halt

A sealing device and electromagnetic technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as unreliable sealing and leakage accidents, and achieve the effects of preventing leakage, improving service life, and avoiding mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

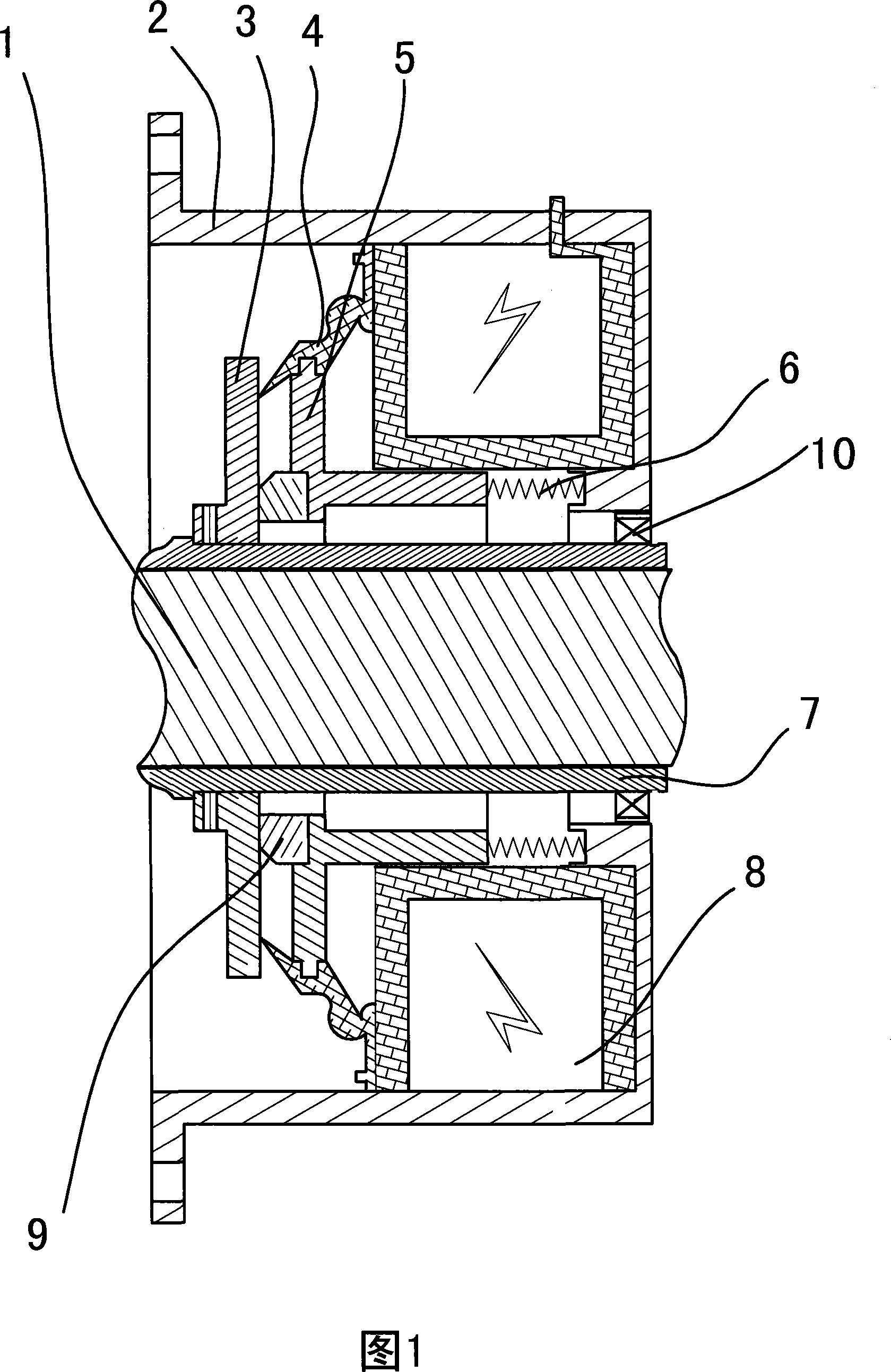

[0023] Embodiment: Referring to the accompanying drawing 1, an electromagnetic sealing device is mainly composed of a static ring 3, a moving ring 5, an electromagnet 8, and a reset elastic element (specifically, four compression springs 6). The static ring 3 is fixed Set on the sealed rotating shaft 1, one end of the static ring 3 is provided with a first sealing working surface arranged around the rotating shaft 1; the moving ring 5 is sleeved outside the rotating shaft 1, and is slidably supported on the sealed shell in the axial direction On the seat, facing the static ring 3, the moving ring 5 is provided with a second sealing working surface arranged around the rotating shaft 1, and the first sealing working surface and the second sealing working surface form a sealing port for blocking leakage; the moving ring 5 It is made of iron, the electromagnet 8 is fixed on the shell seat and acts on the moving ring 5, forcing the second sealing working surface to separate from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com