Long-wall integrated-extraction reclaiming room-type coal column mining method

A technology of coal pillars and longwalls, which is applied in the field of coal mine recovery room mining coal pillars, can solve the problems of low degree of mechanization, in the research stage, and poor production efficiency, and achieve the goals of improving recovery rate, simple method, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

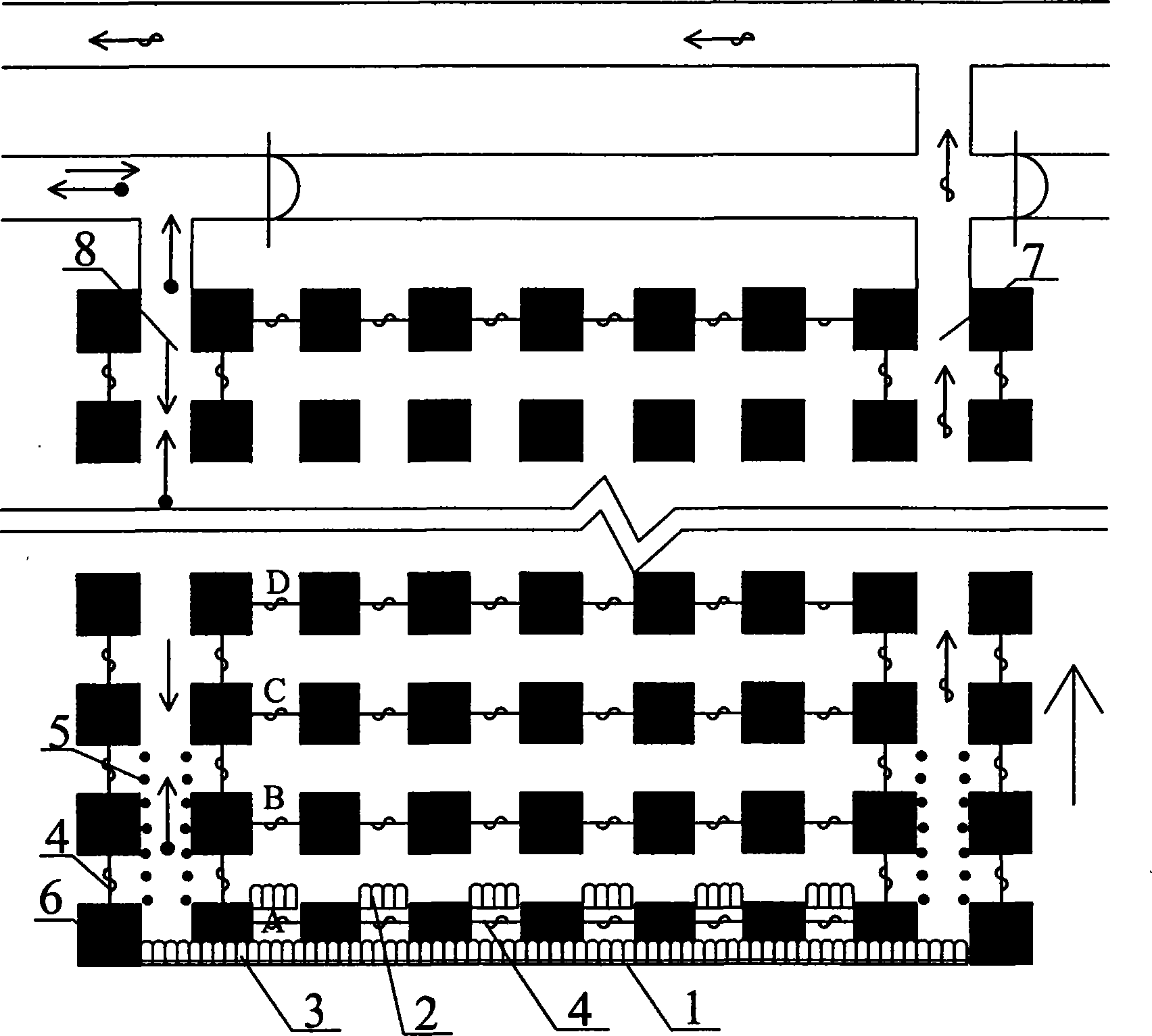

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0019] Take Tongfu Coal Mine of Wulan Group as an example to recover coal pillars by longwall fully mechanized mining. The thickness is 5.30m, the size of the mining coal room is 7.5×9×4.5m, and the size of the coal pillar left in the fully mechanized mining face is 9×9×4.5m. According to the conventional design, the length of the fully mechanized mining face is 120m, and the advancing length of the fully mechanized mining face is 1400m.

[0020] The method of fully mechanized recovery of room type mining coal pillars is as follows:

[0021] (1) Hang the windshield curtain 4 between the first row of coal pillars 6 and the coal pillars in the fully mechanized mining face 1, and hang the windshield 4 between the coal pillars on both sides of the air inlet lane 8 and the air return lane 7 The windshield curtain 4, as shown in the figure: the fresh air passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com