Horizontal well leaching mining method

A technology of horizontal well and mining method, which is applied in the fields of mineral deposit solution leaching mining, horizontal well solution leaching mining method, and mining method, and can solve the problems of large drilling cost, solution leaching dead angle, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

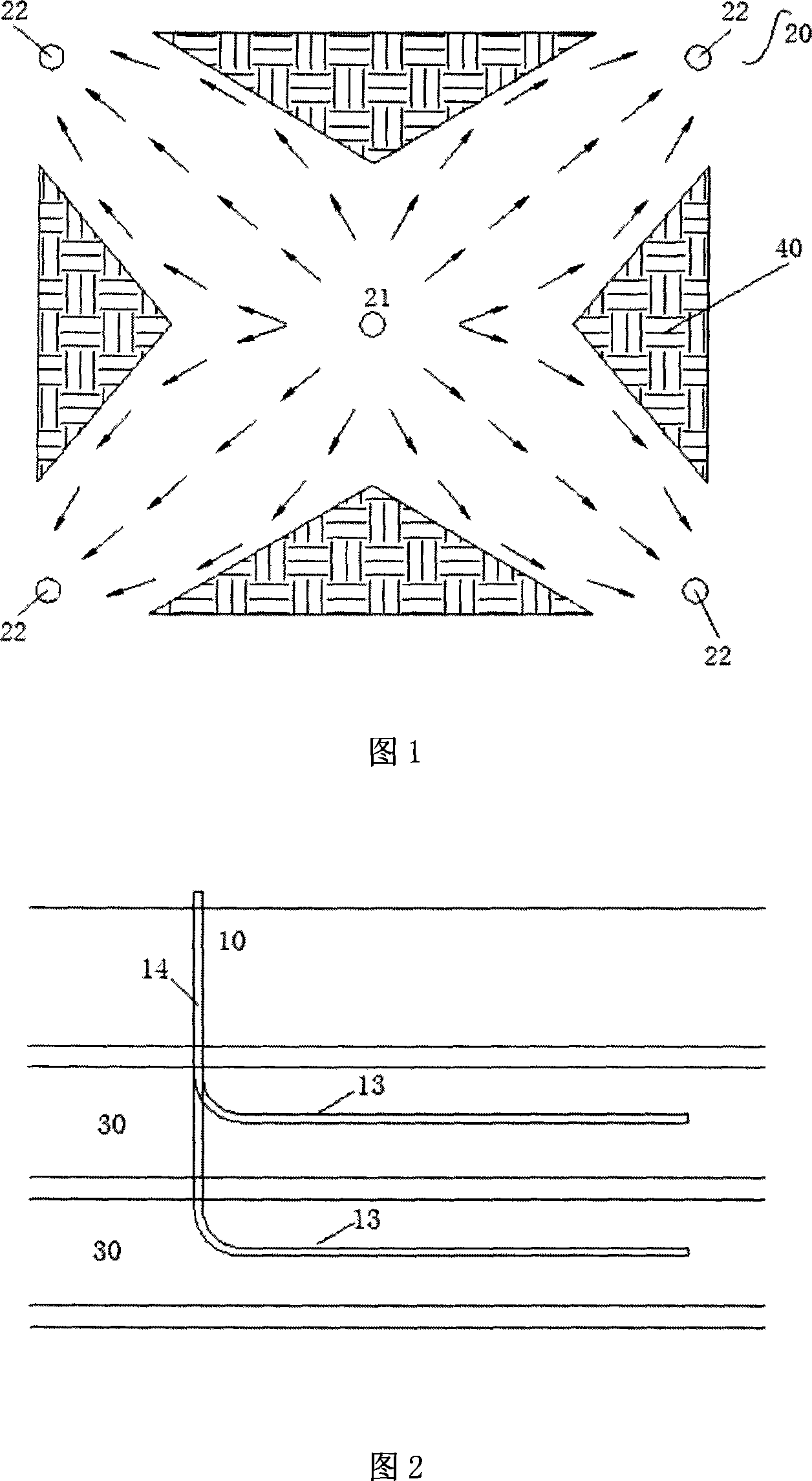

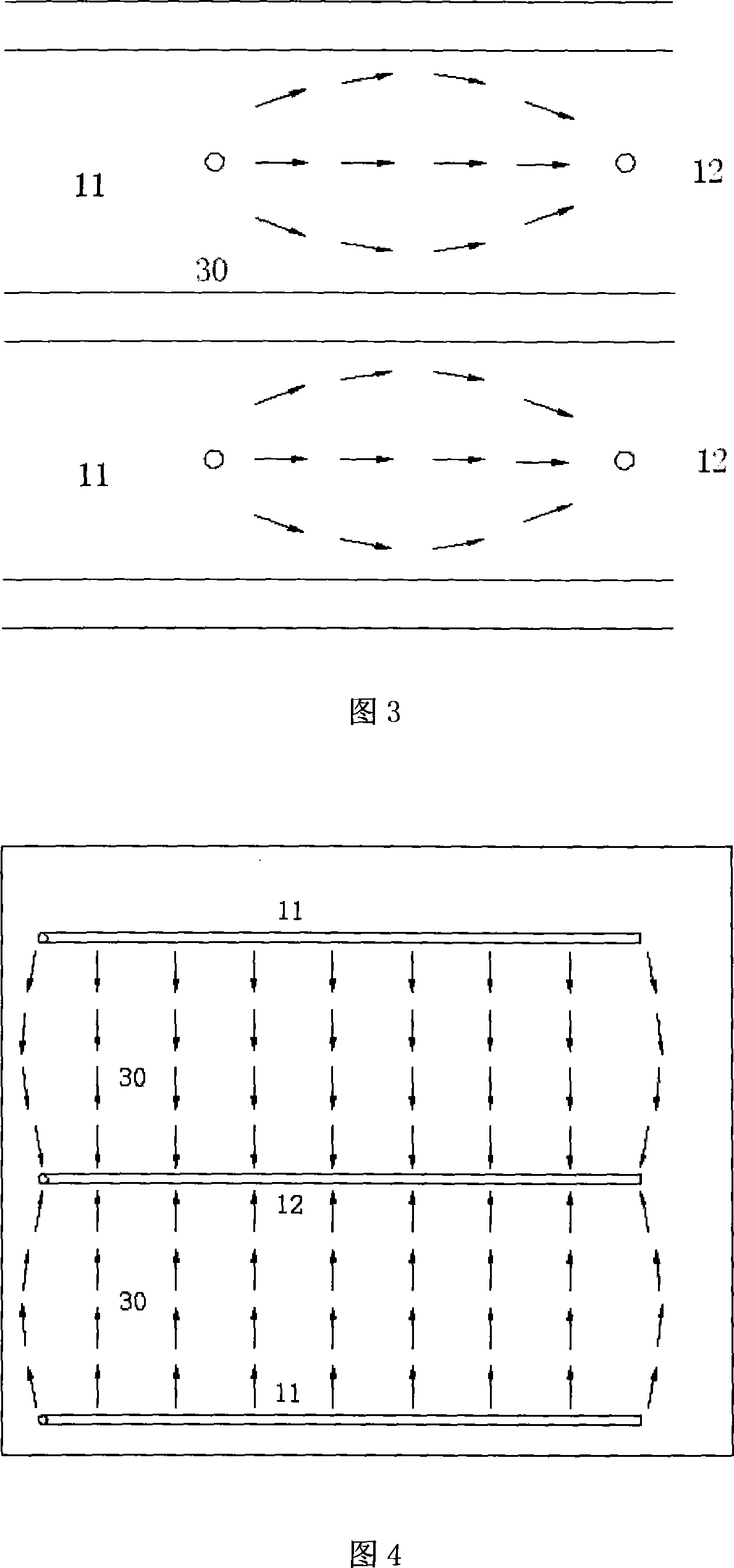

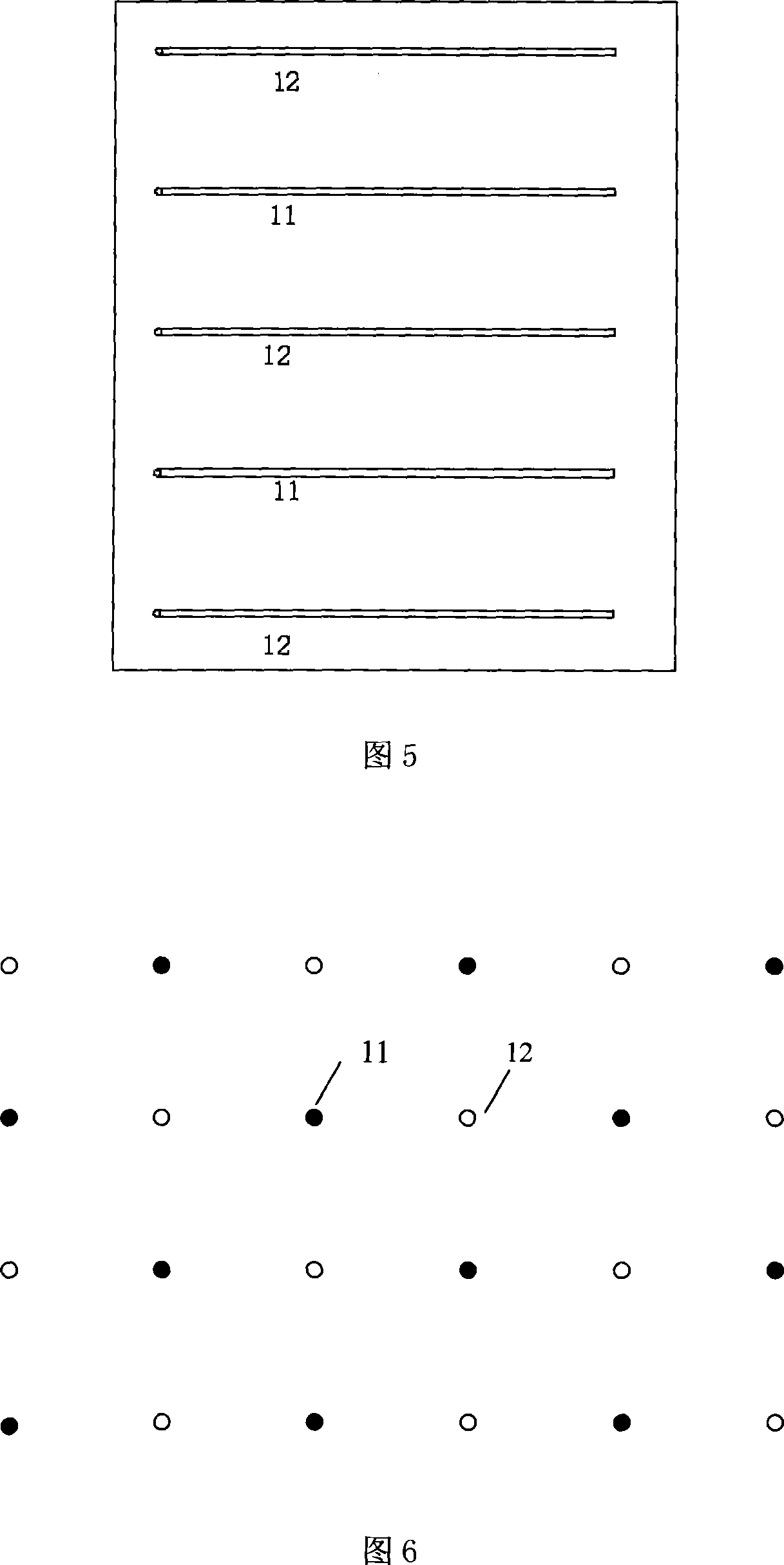

[0040] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0041] 1. About step ①

[0042] The horizontal section (13) and the vertical section (14) of the horizontal well (10) are formed in the ore layer (30) by using the horizontal well technology, as shown in Figure 2, the leaching mainly depends on the horizontal section (13). Horizontal well generation technology already exists in coal, coalbed methane mining, and petroleum fields, and horizontal generation technology is in the leading position in the world (mainly referring to the petroleum sector), and these technologies can be directly used for horizontal well generation. Existing mature horizontal well technologies include: vertical horizontal well, small curvature radius horizontal well, multi-branch horizontal well, pinnate horizontal well and other horizontal well technologies. If there are multiple ore seams, or if the ore seams are very thick, multi-layer h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com