Horizontal fissure fluctuation leaching mining method

A mining method and leaching technology, which is applied in the field of mining method and wave leaching mining method, can solve the problems of leaching dead angle, low mining speed in low-permeability areas, and high drilling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

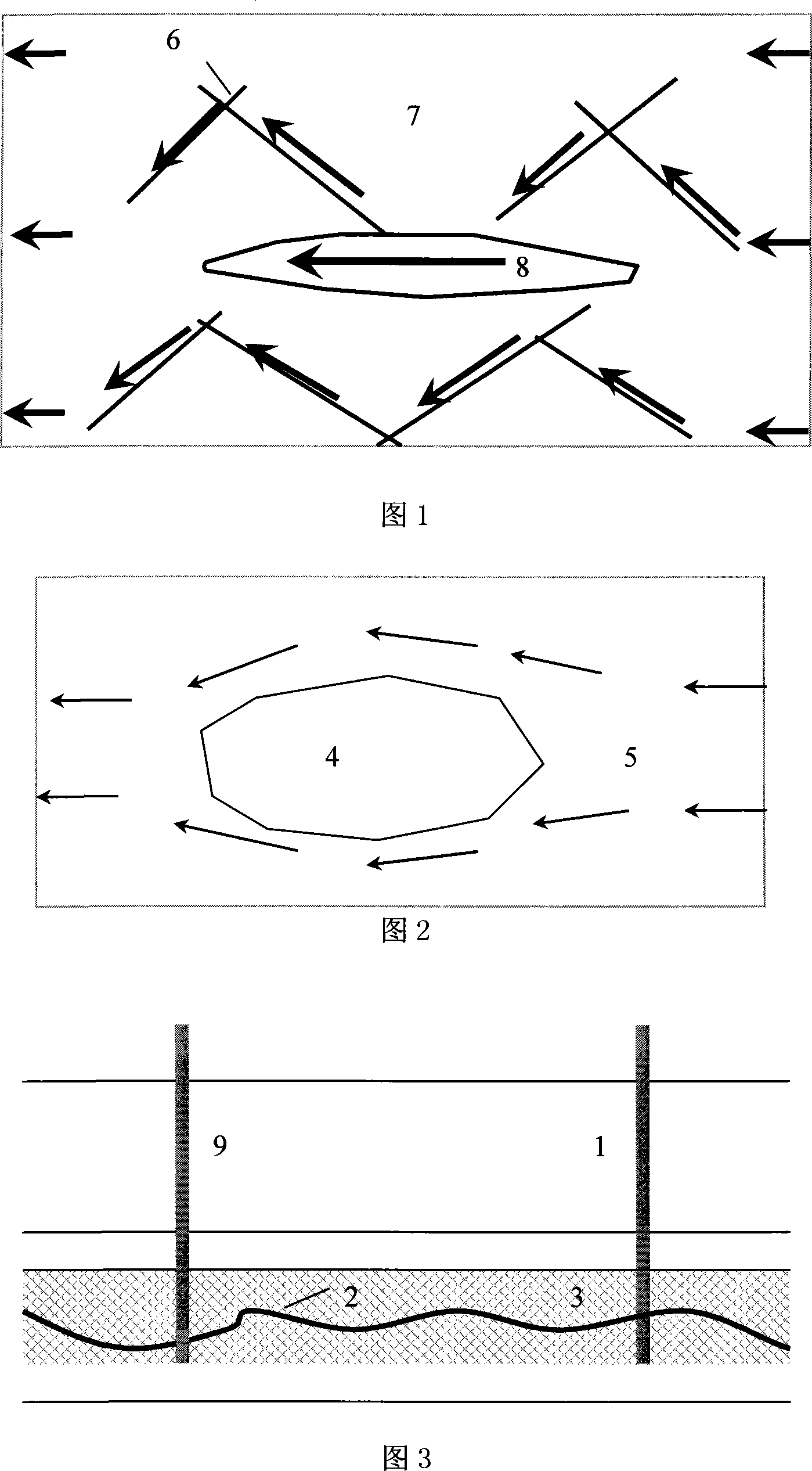

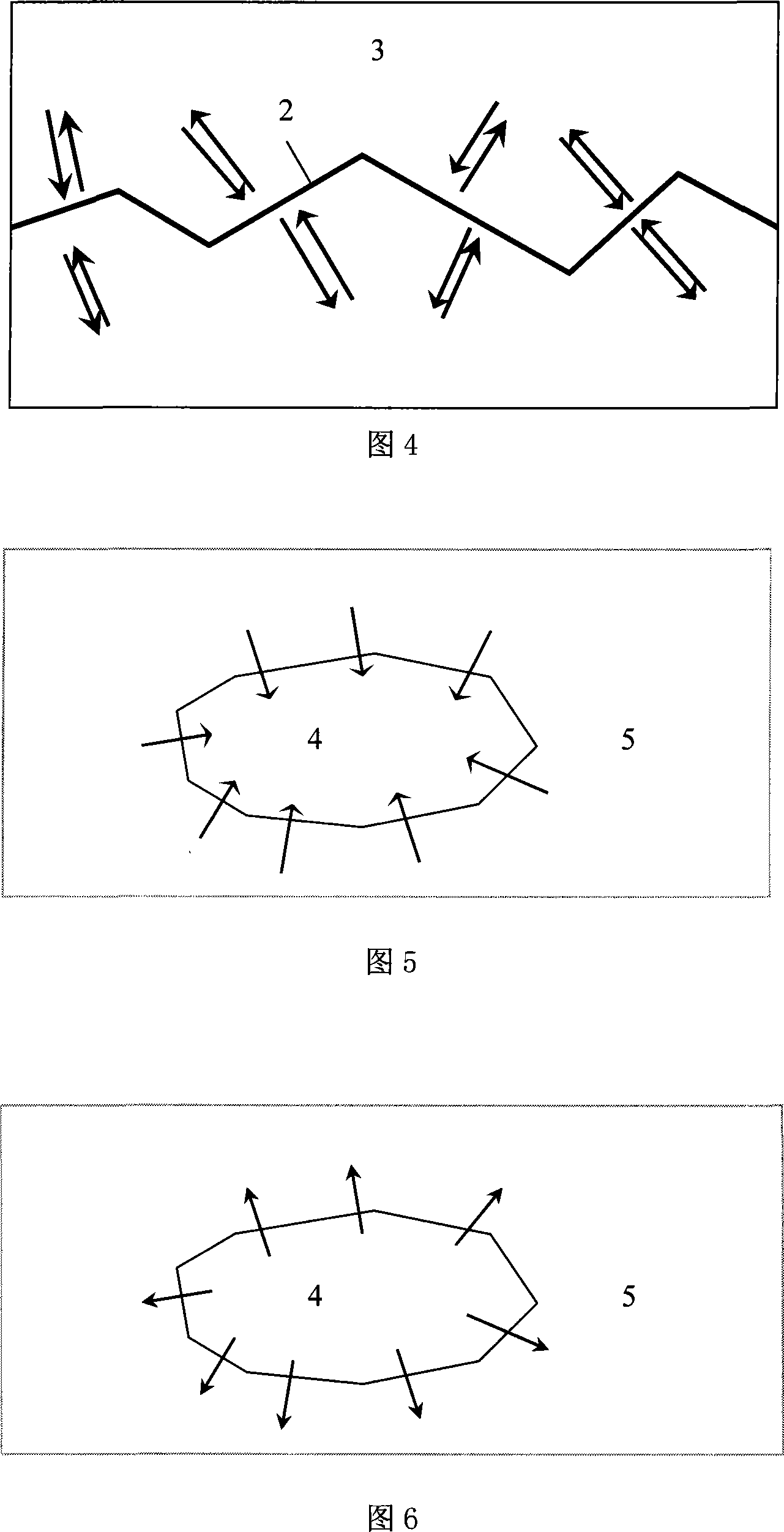

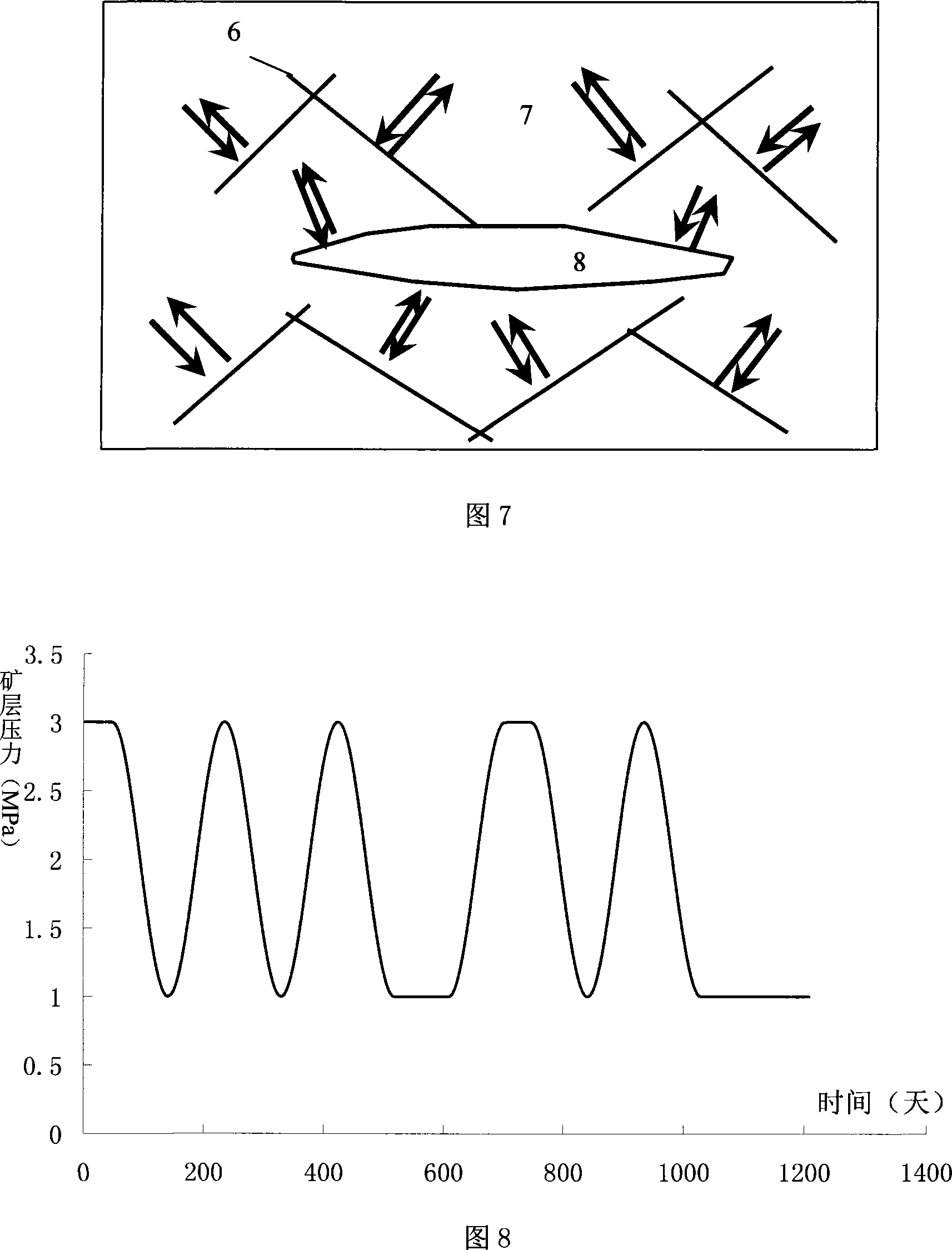

[0045] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0046] 1. About the preparation work

[0047] Through some existing treatment measures (such as: vacuum method, gas filling method, gas displacement, etc.), part of the water in the ore layer (3) is discharged to form an unsaturated rock mass (not all the pores of the rock mass are liquid), so as to contain The highly compressed mixed fluid of the leaching agent enters the hypotonic zone.

[0048] 2. About step ①

[0049] The prerequisite for the horizontal fracture surface (2) is that the entire ore seam has good sealing conditions (cap rock and floor rock with less permeability than the ore seam); The probability of fractures developing from cap rock or floor ensures that horizontal fractures only arise from the ore seam. The conditions for the generation of general horizontal cracks require that the horizontal stress of the ore layer is greater than the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com