Polishing composition for semiconductor wafer, production method thereof, and polishing method

A semiconductor and composition technology, which is applied in the field of semiconductor wafer grinding compositions, and can solve the problems of inability to obtain grinding speed and surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

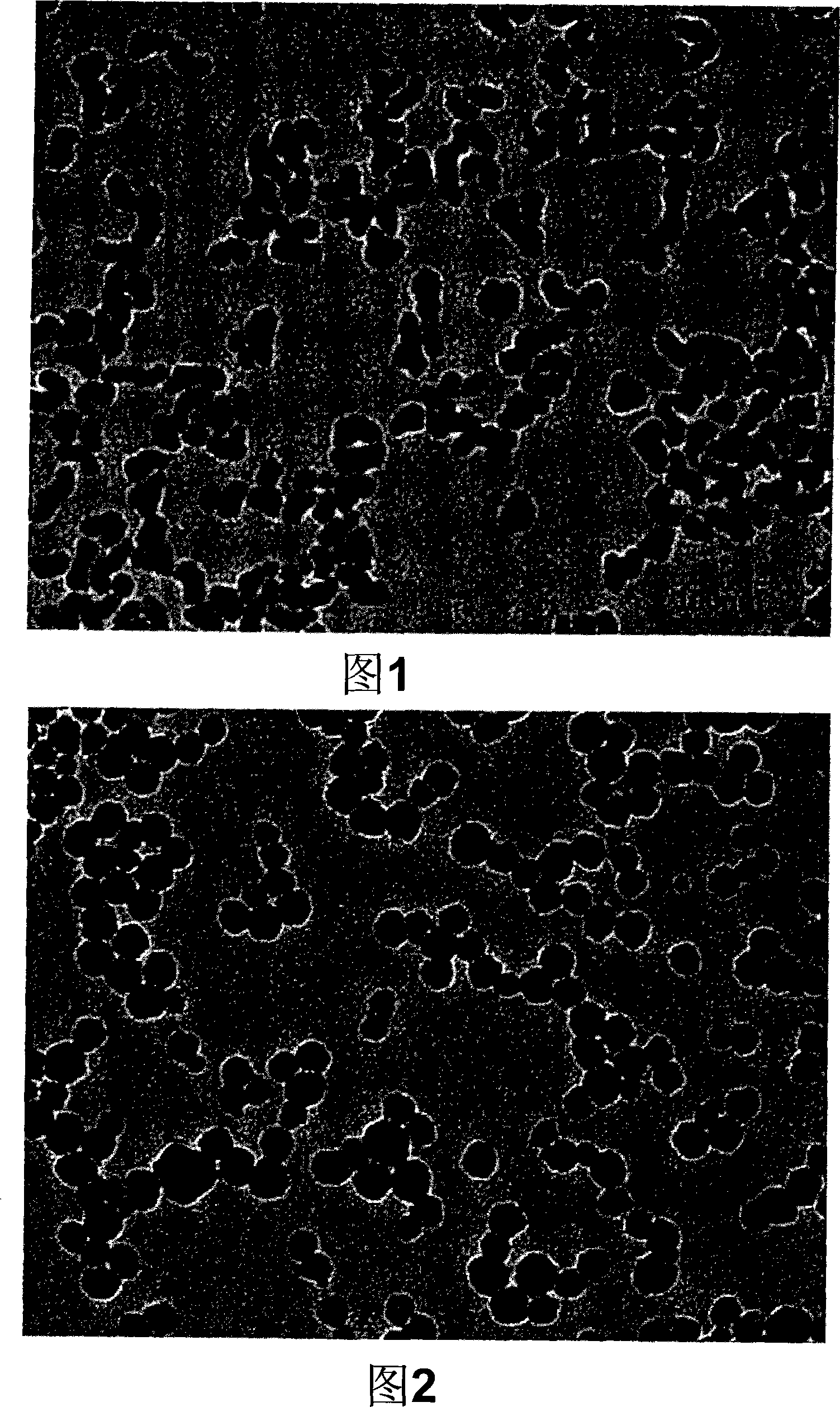

Image

Examples

manufacture example

[0076] Add 520kg JIS No. 3 sodium silicate (sada-silicate) (SiO 2 : 28.8% by weight, Na 2 O: 9.7% by weight, H 2 O: 61.5% by weight), uniformly mixed to prepare diluted sodium silicate with a silicon dioxide concentration of 4.5% by weight. This diluted sodium silicate was passed through a column of 1000 liters of H-type strongly acidic cation exchange resin (AMBERLITE IR120B produced by ORGANO Corporation) regenerated in advance with hydrochloric acid to carry out dealkalization to obtain 3800 kg of silica with a concentration of 3.7% by weight and a pH of 2.9 active silicic acid. In this active silicic acid, the content rates of Na and K per unit of silica were 80 ppm and 5 ppm, respectively. Next, rice uses the method of accumulation to make the colloidal particles grow. That is, to a part of 580 kg of the obtained active silicic acid, a 20% by weight tetramethylammonium hydroxide aqueous solution was added with stirring to adjust the pH to 8.7, and the mixture was kept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com