Electric spanner

An electric wrench and handle technology, applied in the field of wrenches, can solve the problems of too fast movement of the jaws, small driving torque, insufficient rigidity, etc., and achieve the effect of solving inaccurate opening, increasing driving torque, and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

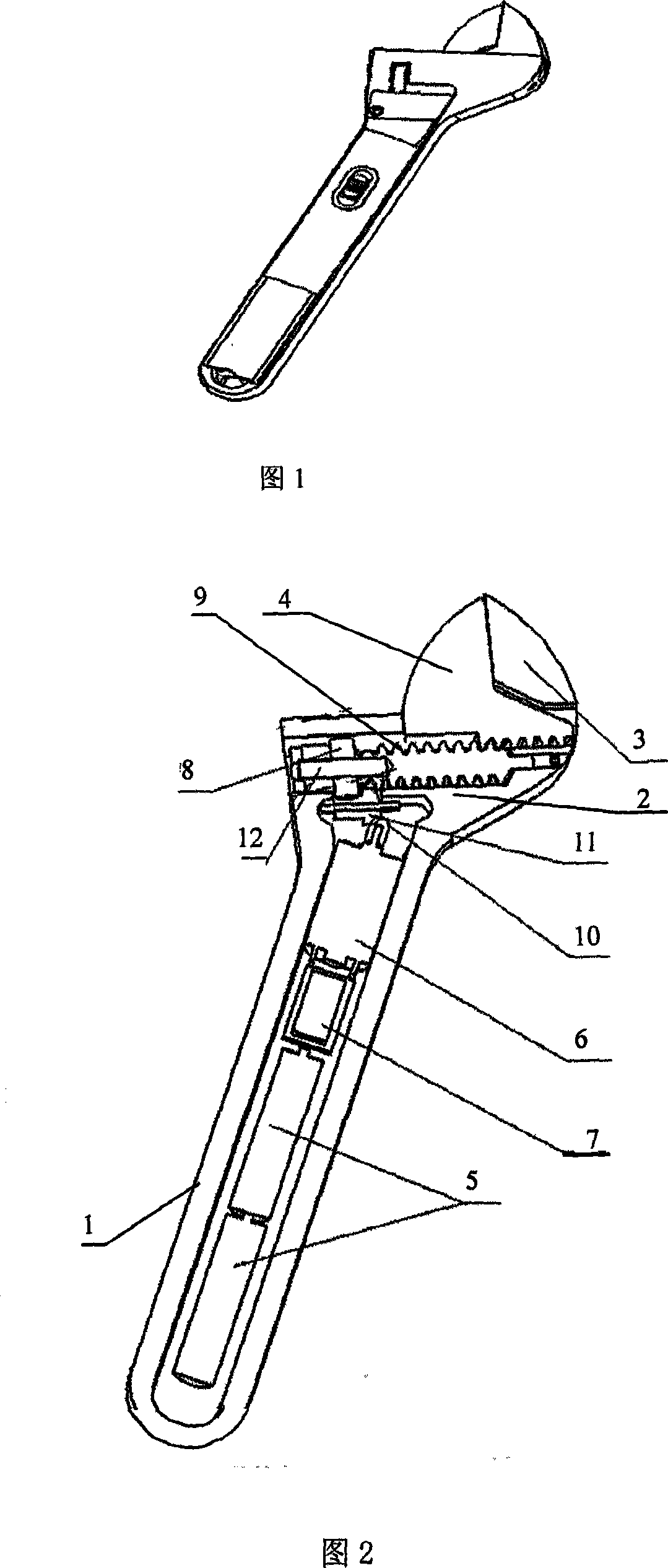

[0009] As shown in the figure: the electric wrench includes a handle 1, a body 2, a fixed jaw 3, a movable jaw 4, a battery 5, a micro motor 6, a double pole double throw switch 7, a spur gear 8, a screw 9 and a primary transmission gear 10 , Intermediate gear 11 and shaft 12. The battery and the micromotor are placed in the preset cavity of the handle, and the forward and reverse rotation of the micromotor is controlled by a double-pole double-throw switch, and the cavity of the handle is covered by a cover. The primary transmission gear, intermediate gear, spur gear and screw rod are placed in the pre-designed cavity of the body, and the spur gear is installed in the cavity through the shaft.

[0010] The battery sends current to the circuit board located at the switch through two wires, and the circuit board then sends electricity to the motor through two output wires as a power source for the motor.

[0011] Since the head of the electric wrench adopts the shape of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com