Convertible embossing device

A technology of printing rollers and operating positions, applied in the field of convertible embossing devices, which can solve the problems of increased reconfiguration time, incompatibility, etc., and achieve the effect of easy manufacturing and good cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

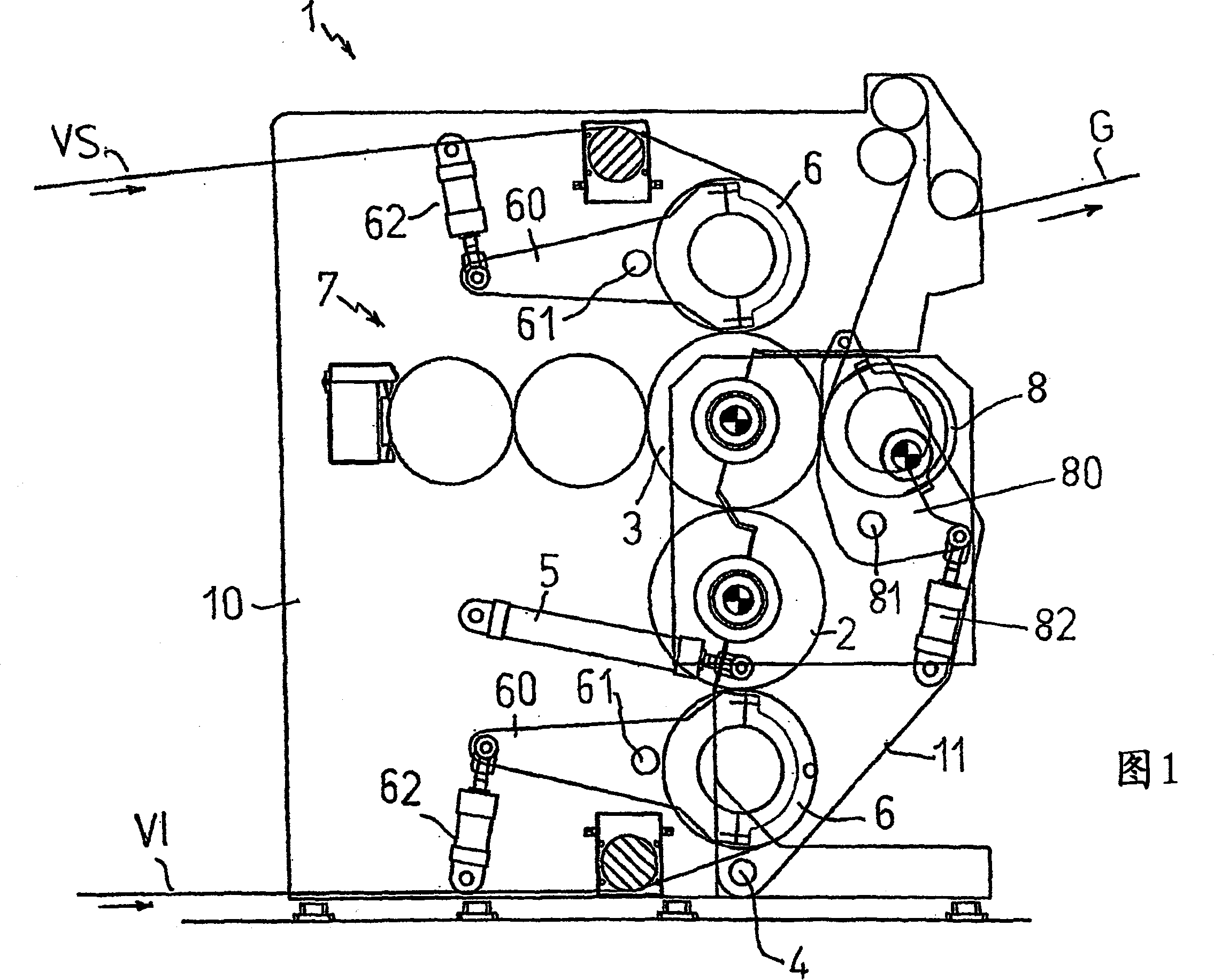

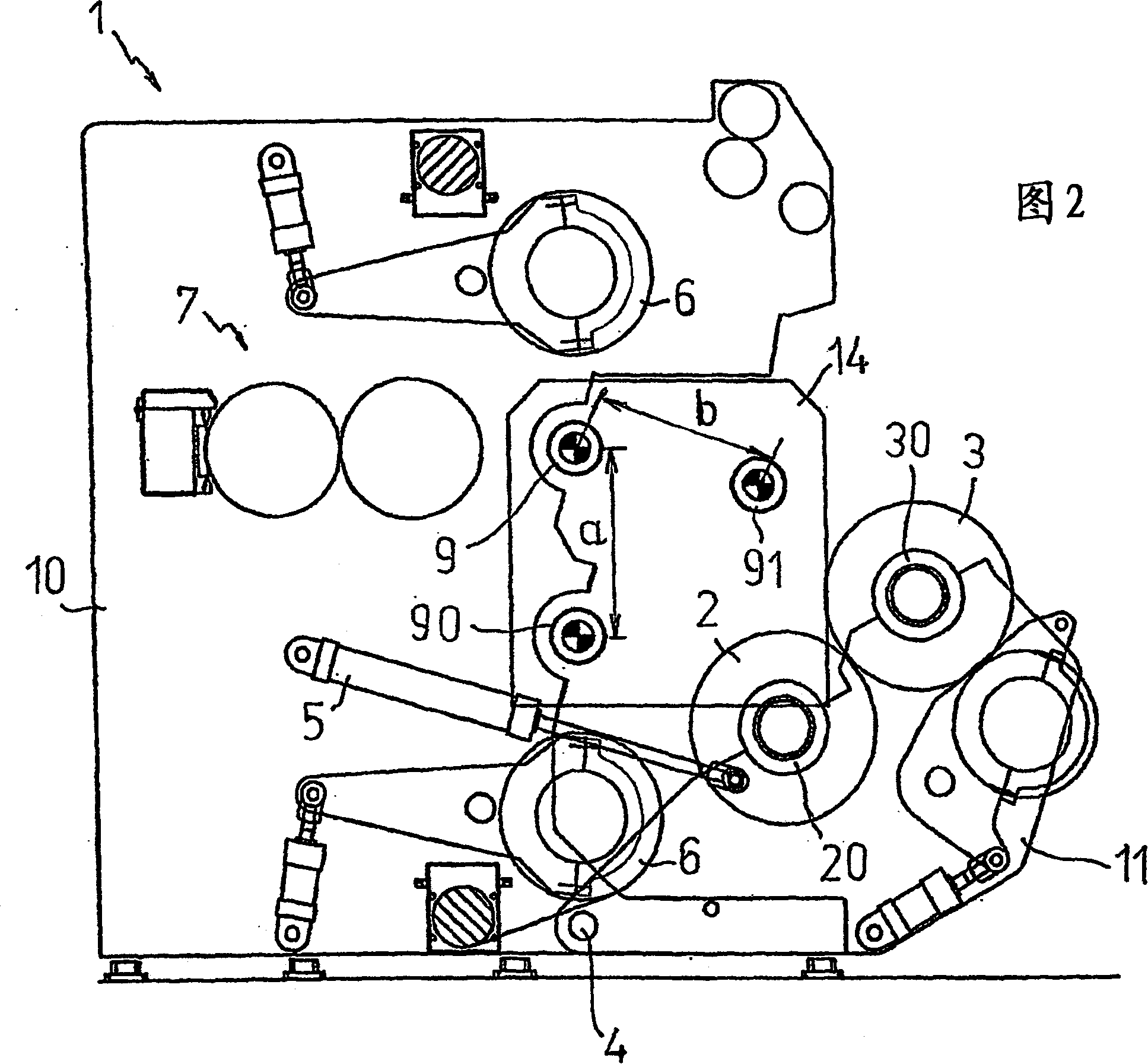

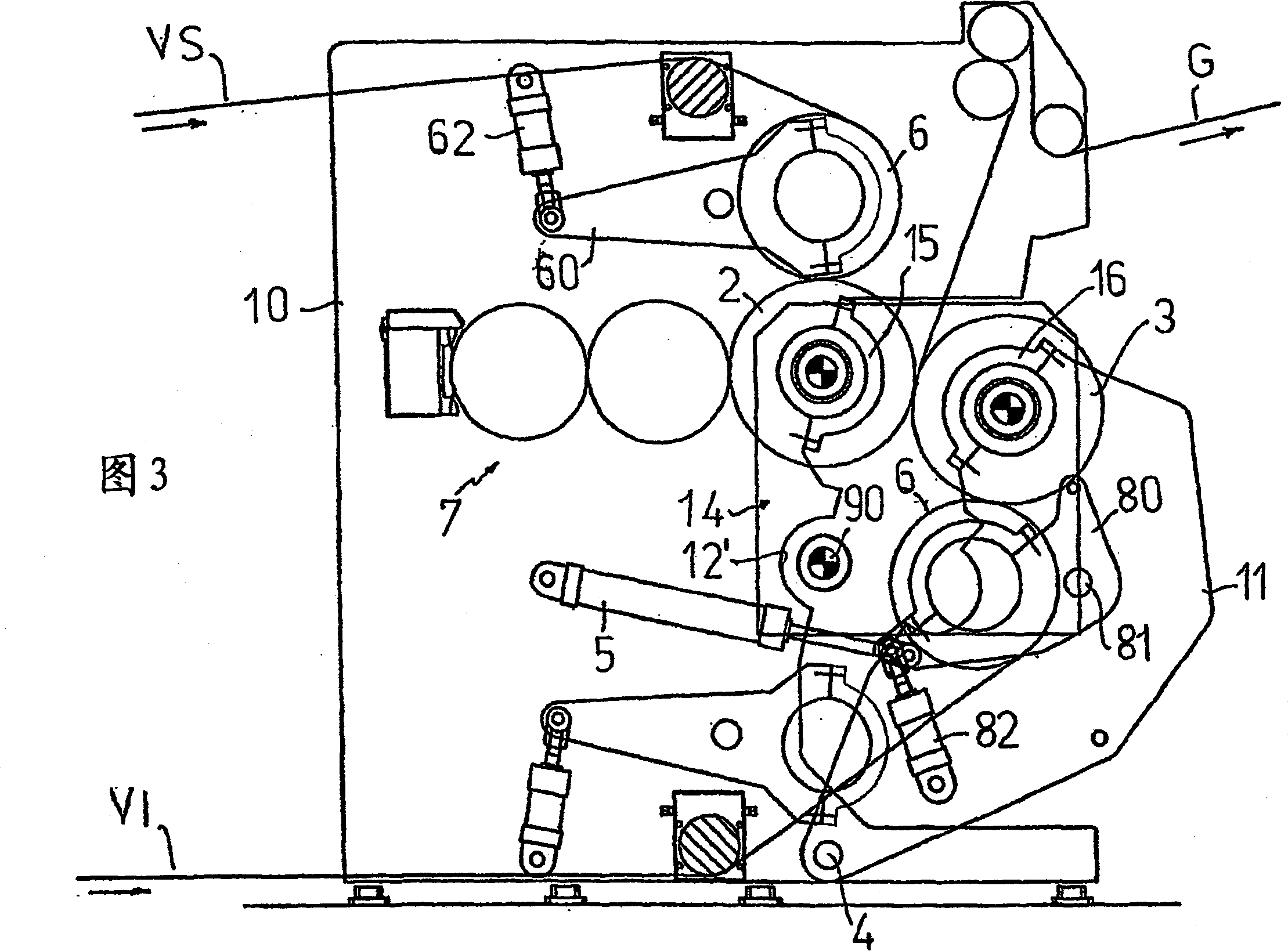

[0014] Reverting to its basic structure and referring to the illustrations in the drawings, the switchable embossing device of the present invention includes a structure 1 having two fixed sides 10, with two movable sides 11 hinged to the two fixed sides 10 on. Each of the fixed side portions 10 has an outer surface EF and an inner surface IF, and the inner surface IF faces the corresponding movable side portion 11. Similarly, each movable side portion 11 has an outer surface EM and an inner surface IM, and the inner surface (1M) faces the related fixed side portion 10. The inner surface IF of each fixed side portion 10 has two circular arc-shaped notches 12, 12', one notch 12 is set slightly higher, and the other notch 12' is set slightly lower. The inner surface IM of each movable side portion 11 has two similar notches 13, 13', and these notches are also arc-shaped. To be better described in detail below, the notches 12, 12', 13, 13' provided in the inner surfaces IF, IM of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com