On-line monitoring methods for high-voltage circuit-breaker switching on-off time

A technology of high-voltage circuit breakers and circuit breakers, which is applied in the direction of circuit breaker testing, etc., can solve the problems of deviation in measurement results, poor conversion speed, and inability to locate, achieve accurate accuracy requirements, and simple determination of contact opening/closing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

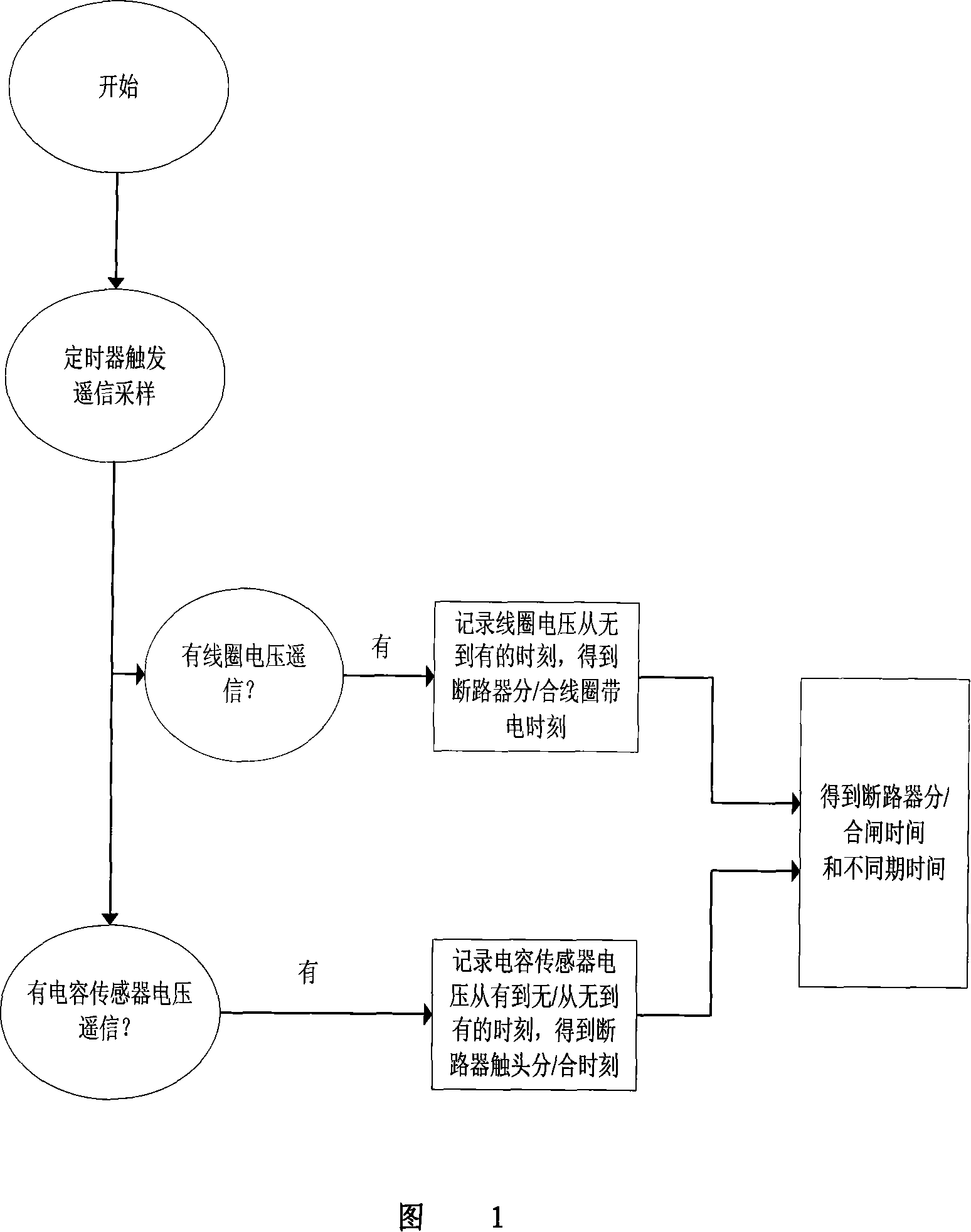

[0031] As shown in Figure 1, in the embodiment of the online monitoring method of the opening and closing time of the high-voltage circuit breaker of the present invention, the timer of the online monitoring device CPU triggers the three-phase capacitance sensor of the opening / closing coil of the circuit breaker and the high-voltage charged display device Carry out voltage signal remote signal sampling, the sampling frequency is 10000Hz, so that the monitoring time accuracy is 0.1 millisecond:

[0032] Determination of 1 minute / closing coil electrification time

[0033] Sampling the voltage remote signal of the opening coil and closing coil of the circuit breaker, and recording the remote signal displacement time of the opening / closing circuit during the opening / closing operation, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com