Coal mine gas detecting and draught fan automatic control system

An automatic control system and coal mine gas technology, applied in the direction of gas discharge, mining equipment, mining equipment, etc., can solve the problems of small ventilation operation, different exhaust air volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

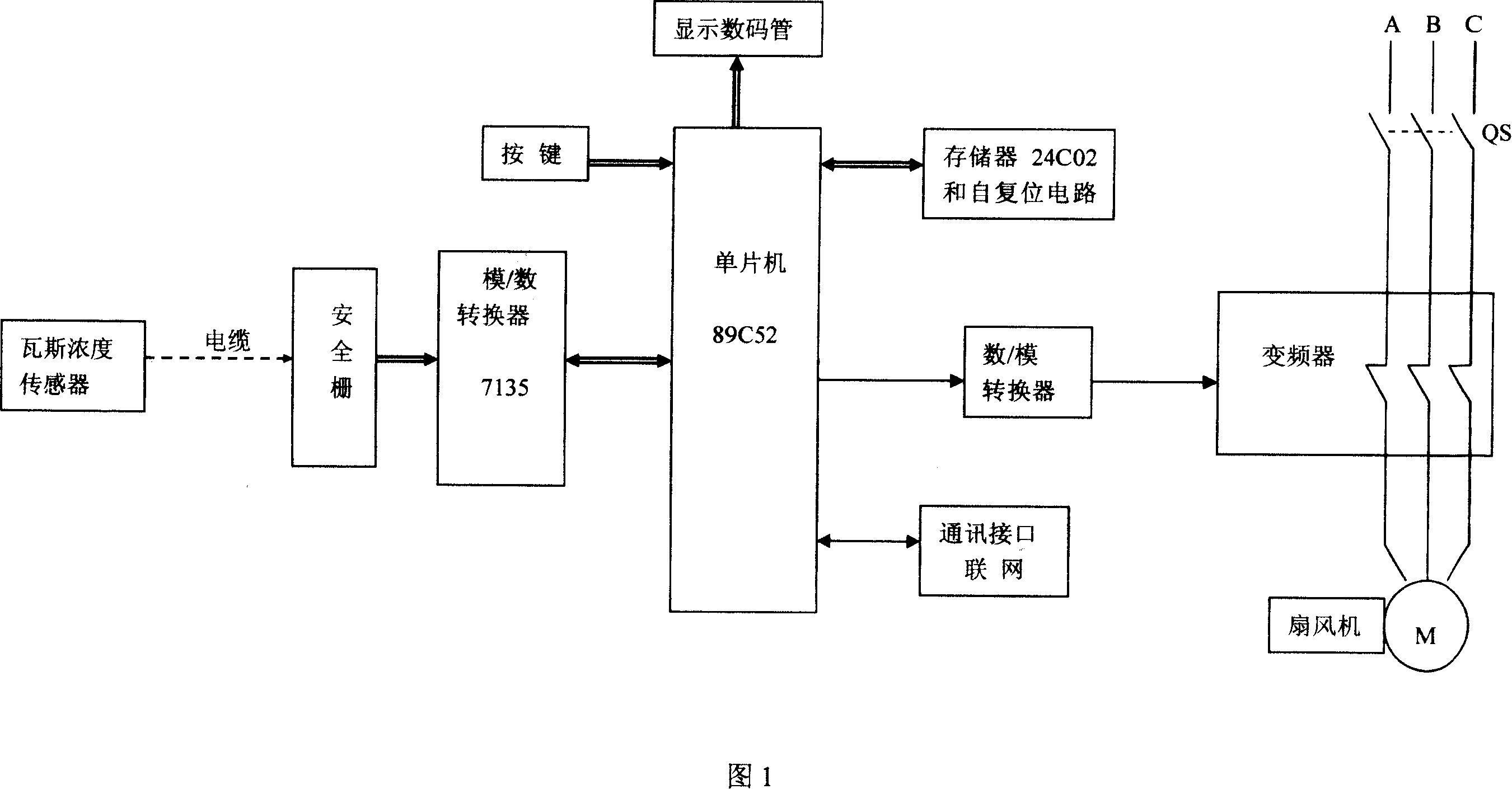

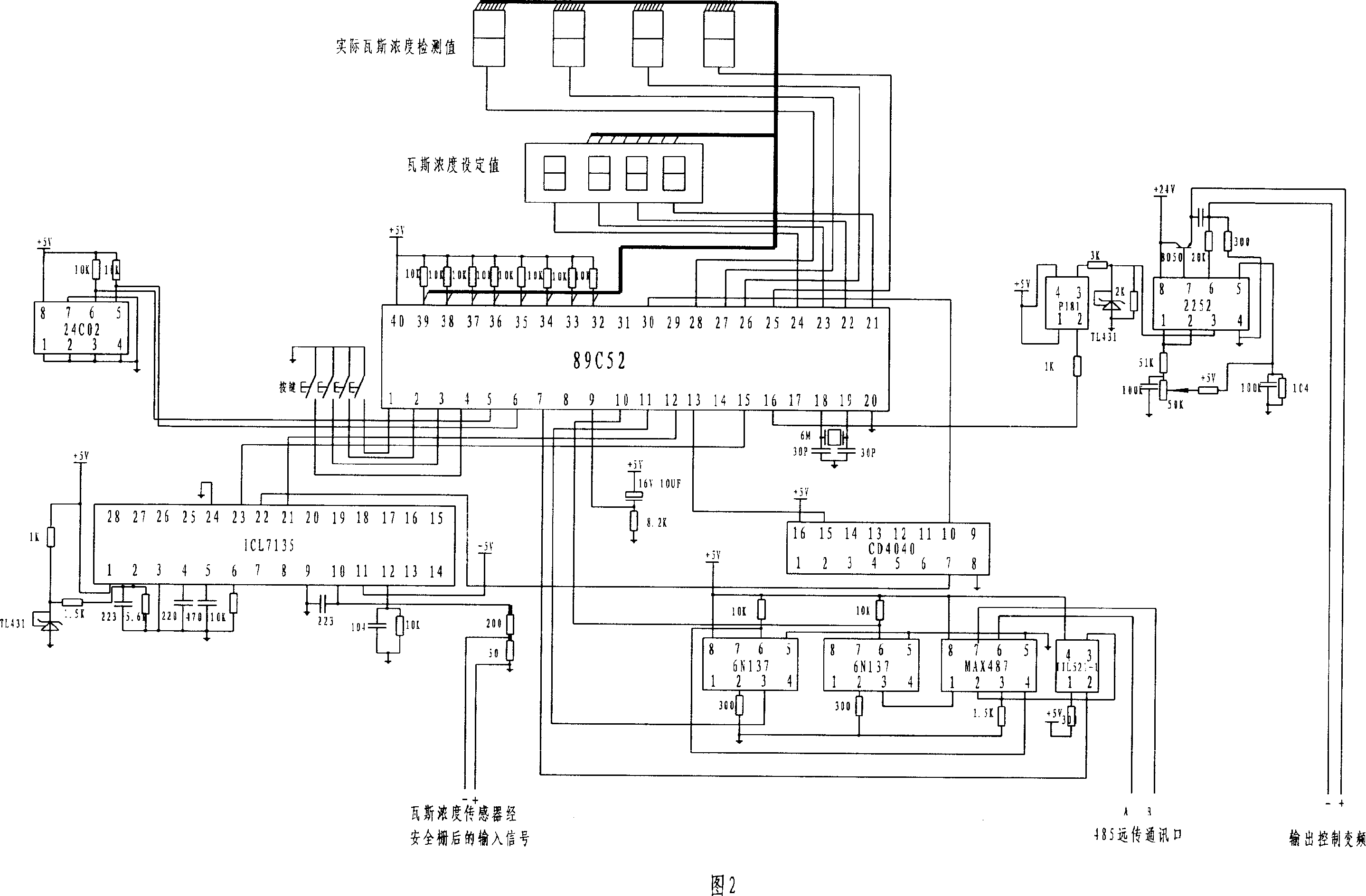

[0006] Specific embodiment: this coal mine gas detection of the present invention and blower automatic control system (see accompanying drawing) have the blower blower of coal mine and tunnel exhaust, the input end of blower blower is connected with frequency converter, and frequency converter passes digital / analog converter It is connected with the output end of the single-chip microcomputer, and the input end of the single-chip microcomputer is connected with the gas concentration sensor through the analog / digital converter connected in sequence, the safety barrier, and the other input and output of the single-chip microcomputer are respectively corresponding to the buttons and digital tubes showing the measured concentration and the set concentration connect. The single-chip microcomputer is also connected with the memory and the reset circuit; the single-chip microcomputer is also connected with a communication interface. The gas concentration sensor is installed at the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com