Brush bristle material and brush

A technology of bristles and brushes, applied in the field of bristle materials and a kind of brush, can solve the problems of inaccessibility to workpieces and scattered bristles, and achieve the effect of easy operation and enhanced grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

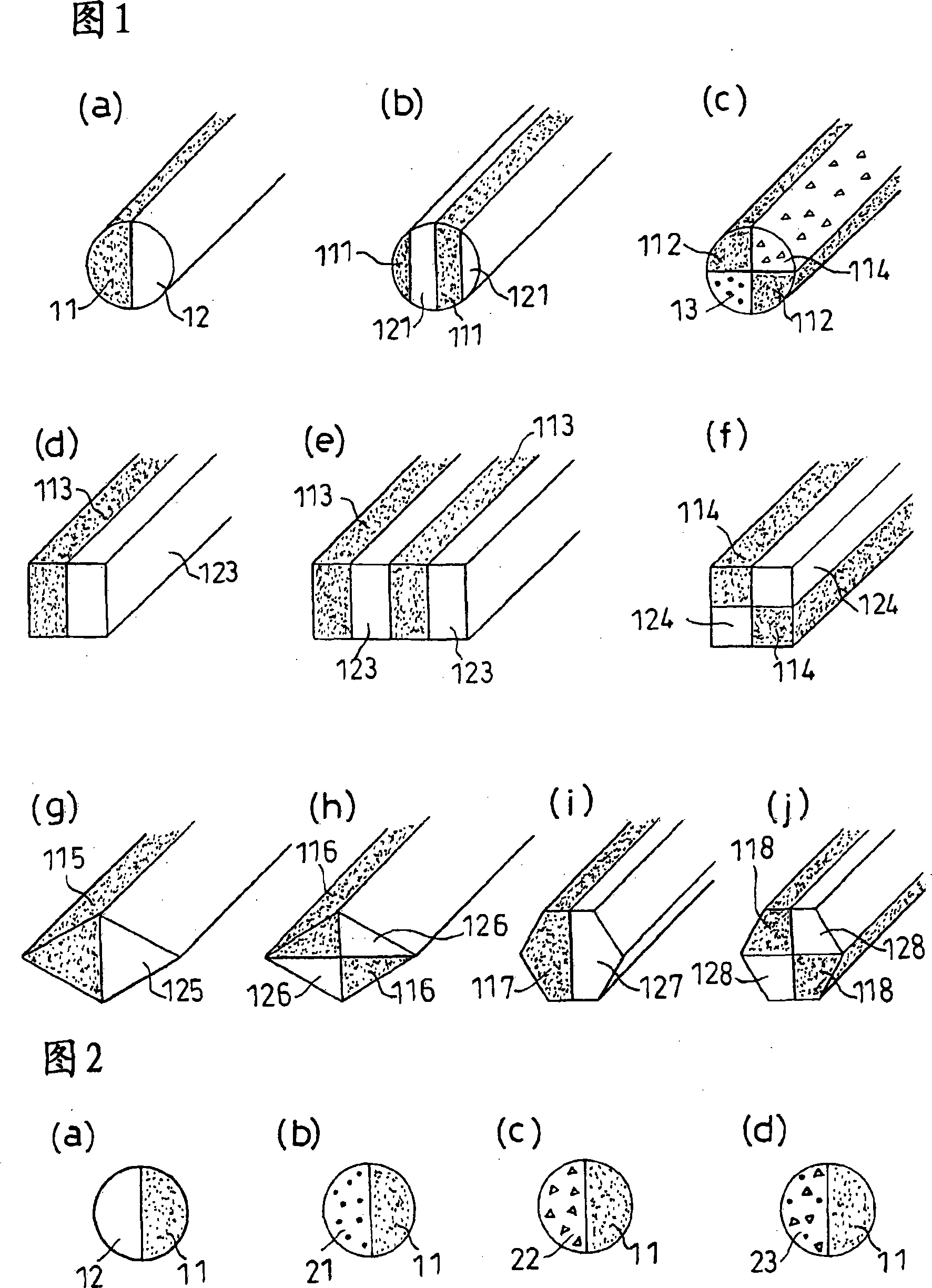

[0048] 1(a)-1(j) are perspective views showing Embodiment 1 of the present invention, respectively showing a bristle material formed by combining a synthetic resin material and a metal material with each other. The bristle material shown in FIG. 1( a) is a circular strip, and is formed by combining metal material 11 and synthetic resin material 12 by thermocompression bonding or thermal welding. The bristle material shown in Figure 1(b) is a circular strip, and the synthetic resin material 121 is inserted between two metal materials 111 that are close to flat plates, and the other synthetic resin material is placed on the metal material like a sandwich. 111 formed on the other side.

[0049] The bristle material shown in Fig. 1 (c) is a circular strip, which is composed of two metal materials 112 each accounting for a quarter circle of the cross section, one also accounting for a quarter circle of the cross section and It is made of a synthetic resin material 13 that contains...

Embodiment 2

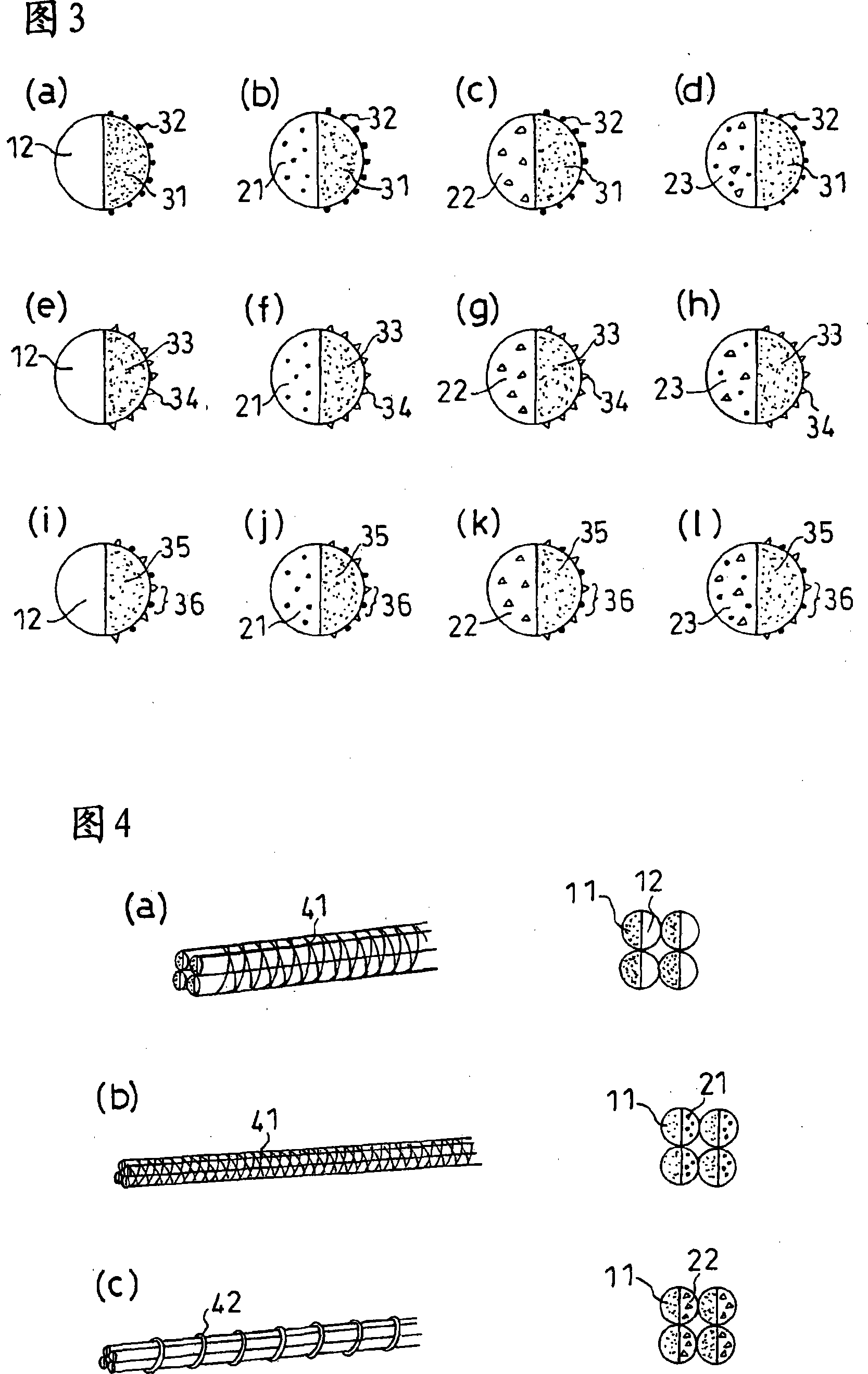

[0054] 2(a) to 2(d) are cross-sectional views of Embodiment 2 of the present invention, each showing a mixture of abrasive particles in a synthetic resin material. The bristle material of Fig. 2 (a) is a kind of approximately circular strip, is that the synthetic resin material 12 that each cross section is semicircle and the same metal material 11 that cross section is semicircle are mutually combined and formed. The bristle material shown in FIG. 2(b) is formed by mixing honing grains, grinding grains, flavoring grains or other similar substances in a synthetic resin material 21 having a semicircular cross section. The particles mixed into the synthetic resin material can optionally have different shapes and material qualities depending on the grinding purpose. The material quality type and / or quantity of the substance mixed into the synthetic resin material 21 to 23 can be selected from abrasive grains 21, diamond grains 22, abrasive grains and diamond grains as shown in Fi...

Embodiment 3

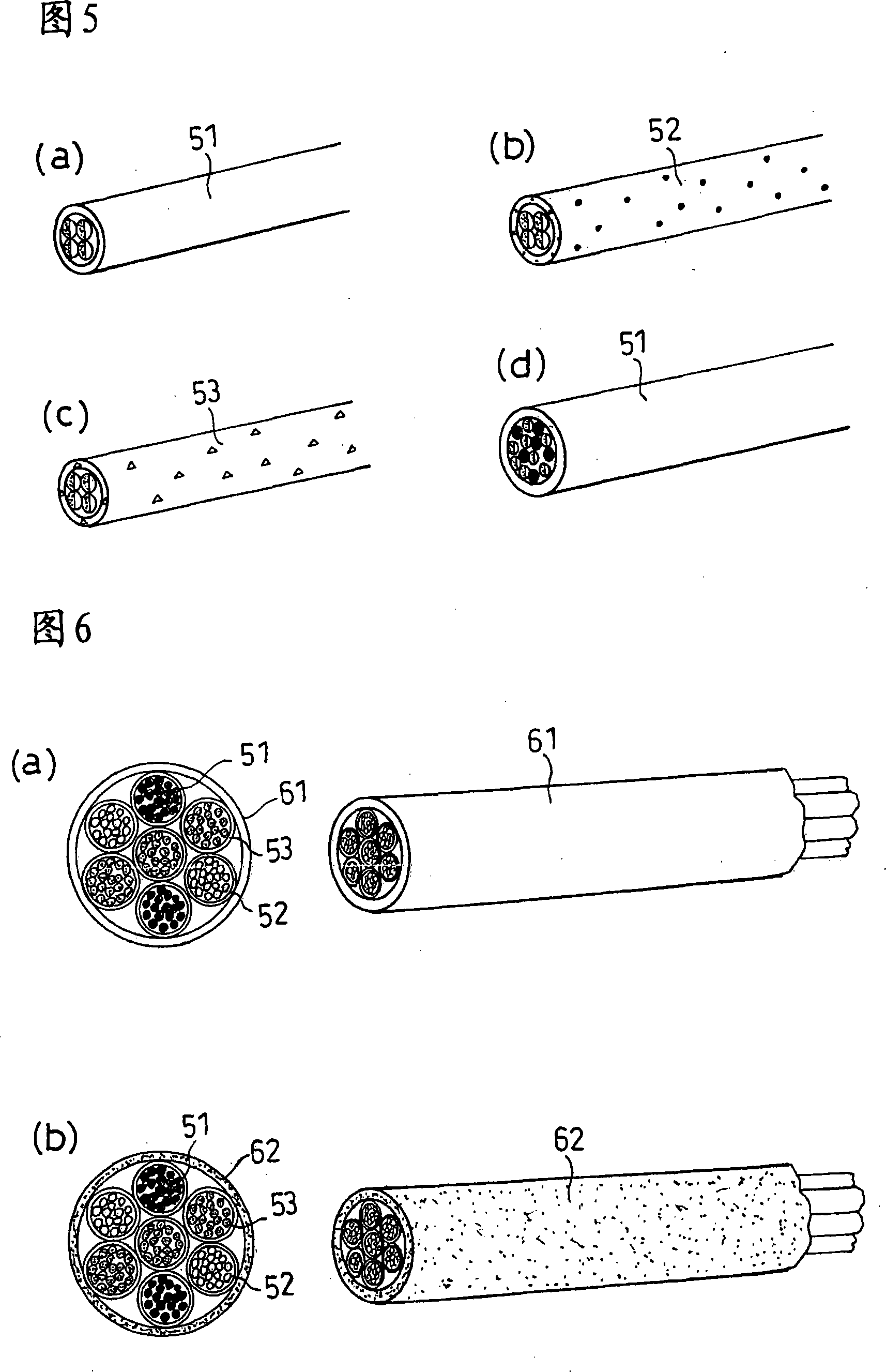

[0056] 3( a )- FIG. 3( l ) are cross-sectional views of Embodiment 3 of the present invention, each showing a state in which abrasive particles are attached to the periphery of the metal material. The form of the bristle material shown in FIG. 3( a ) is that, for example, abrasive particles 32 are attached to a metal material 31 with a semicircular cross-section by means such as electrodeposition, welding, electroplating or vapor deposition. Then, the metallic material 31 coats the abrasive grains 32 on its surface as if by electroplating. The cladding may be applied to the metal material 31 at a uniform thickness, although not shown. The bristle material of the bar-shaped body, which is made of the metal material 31 and the synthetic resin material 12 through mutual bonding, is similar to the bristle material shown in FIG. 2 . The bristle material shown in Fig. 3(b) is a strip, which is composed of a synthetic resin material 21 with abrasive particles inside and a metal mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com