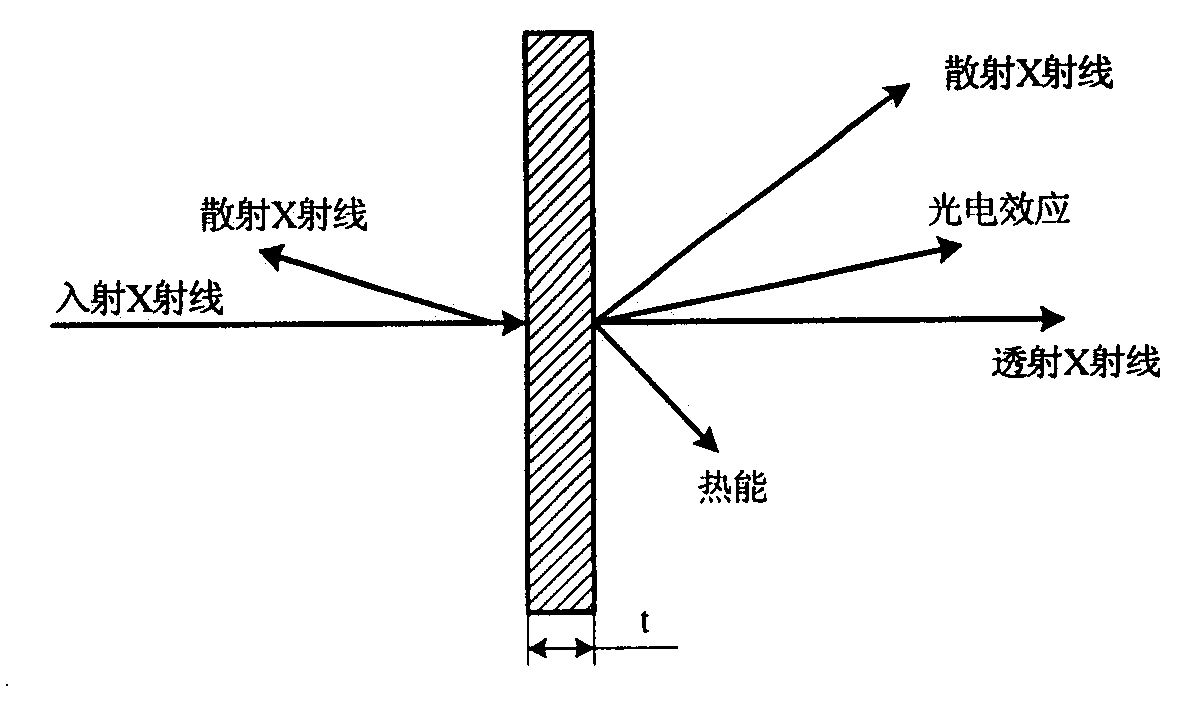

Device for testing explosive with backscatter technology

A technology of backscattering and explosives, which is used in material analysis using radiation, measuring devices, material analysis using wave/particle radiation, etc. source and other issues to achieve the effect of increasing the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0019] Such as figure 2 As shown, a device for detecting explosives using backscattering technology provided by the present invention includes a wheel-cutting collimator 1, an X-ray source 2 arranged at the axial center of the wheel-cutting collimator 1, and a wheel-cutting collimator A driving mechanism 3 is also arranged under the straightener;

[0020] The cutting wheel collimator 1 is evenly provided with a number of collimating holes 101 in the radial direction, and the X-rays are collimated into a spot with a small diameter within a fixed X-ray emission range, and the rotating drive mechanism 3 drives the cutting wheel collimator. The collimator 1 rotates around the X-ray source 2 to scan the light spot from bottom to top or top to bottom.

[0021] The rotary drive mechanism 3 includes a fixed support frame 301 and a motor 302; the fixed support frame 301 supports the wheel-cutting collimator 1;

[0022] The device for detecting explosives using backscatter technology...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com