Multi-speed countershaft transmission with a planetary gear set

A technology for planetary gear sets and intermediate shafts, applied to components with teeth, vehicle gearboxes, gear transmissions, etc., to reduce cooling requirements and improve fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

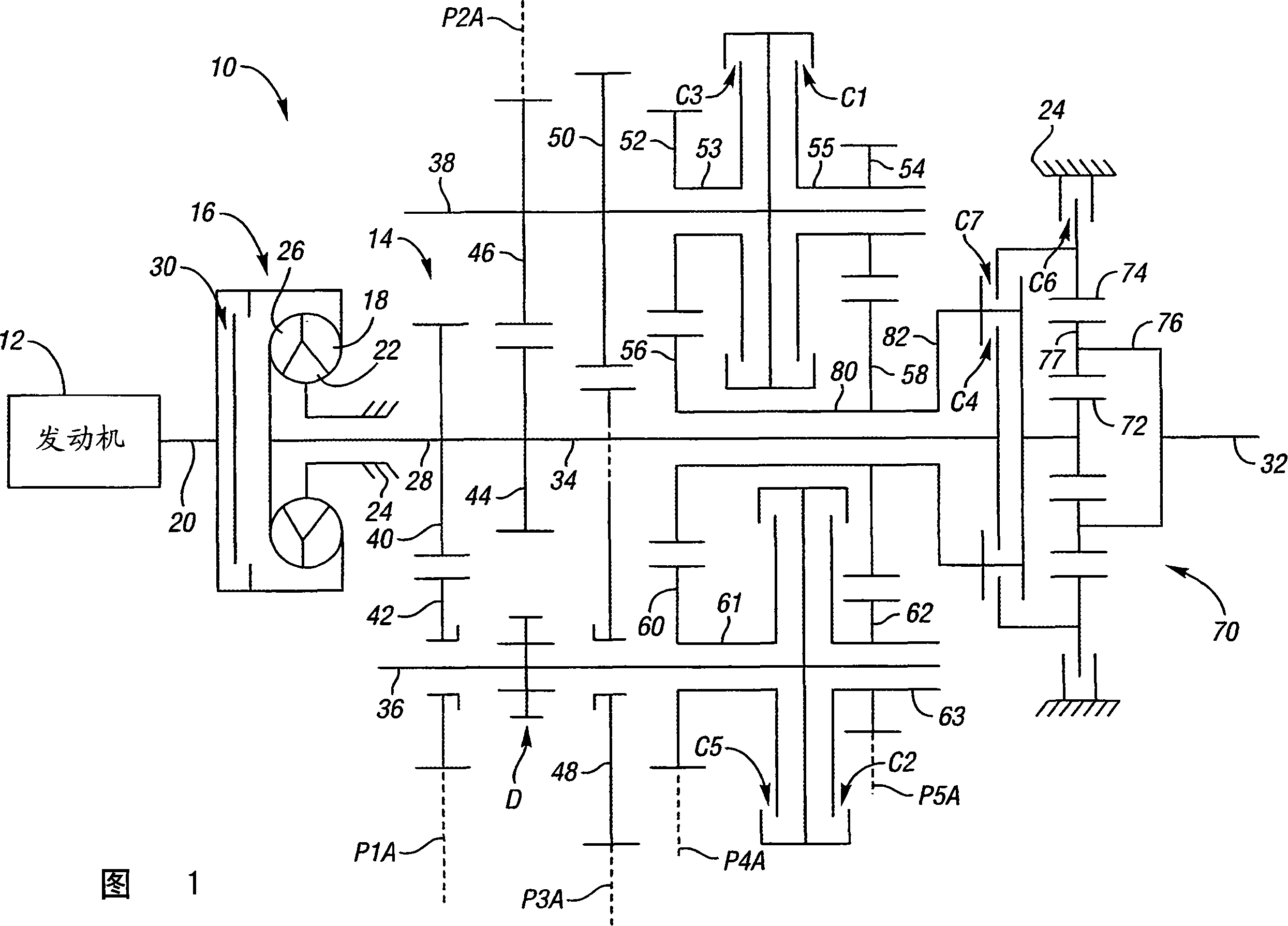

[0027] Referring to the drawings, wherein like numerals refer to like components, FIG. 1 shows a powertrain 10 including an engine 12 operably connected to a transmission 14 via a torque converter 16 . Torque converter 16 includes a pump portion 18 connected for rotation to an engine shaft 20 , an idler portion 22 secured to a stationary element such as a transmission housing or housing 24 , and a turbine portion 26 . Those of ordinary skill in the art will appreciate that the torque converter 16 is a fluid coupling that provides torque augmentation between the pump portion 18 and the turbine portion 26 . Turbine portion 26 is connected for rotation with an input member 28 of transmission 14 . The torque converter 16 includes a lock-up clutch 30 . When the lock-up clutch 40 is engaged, power flow from the engine shaft 20 is directly connected to the input member 28 , bypassing the hydraulic coupling and torque build-up of the pump section 18 and turbine section 26 .

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com