Cast-in-situ concrete hollow slab

A technology of cast-in-place concrete and cast-in-place concrete, which is applied to floors, building components, buildings, etc., can solve the problems of low strength, low rigidity, and high damage rate of formwork components, so as to improve the ability of impact resistance and damage. Improve the bearing capacity and improve the effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

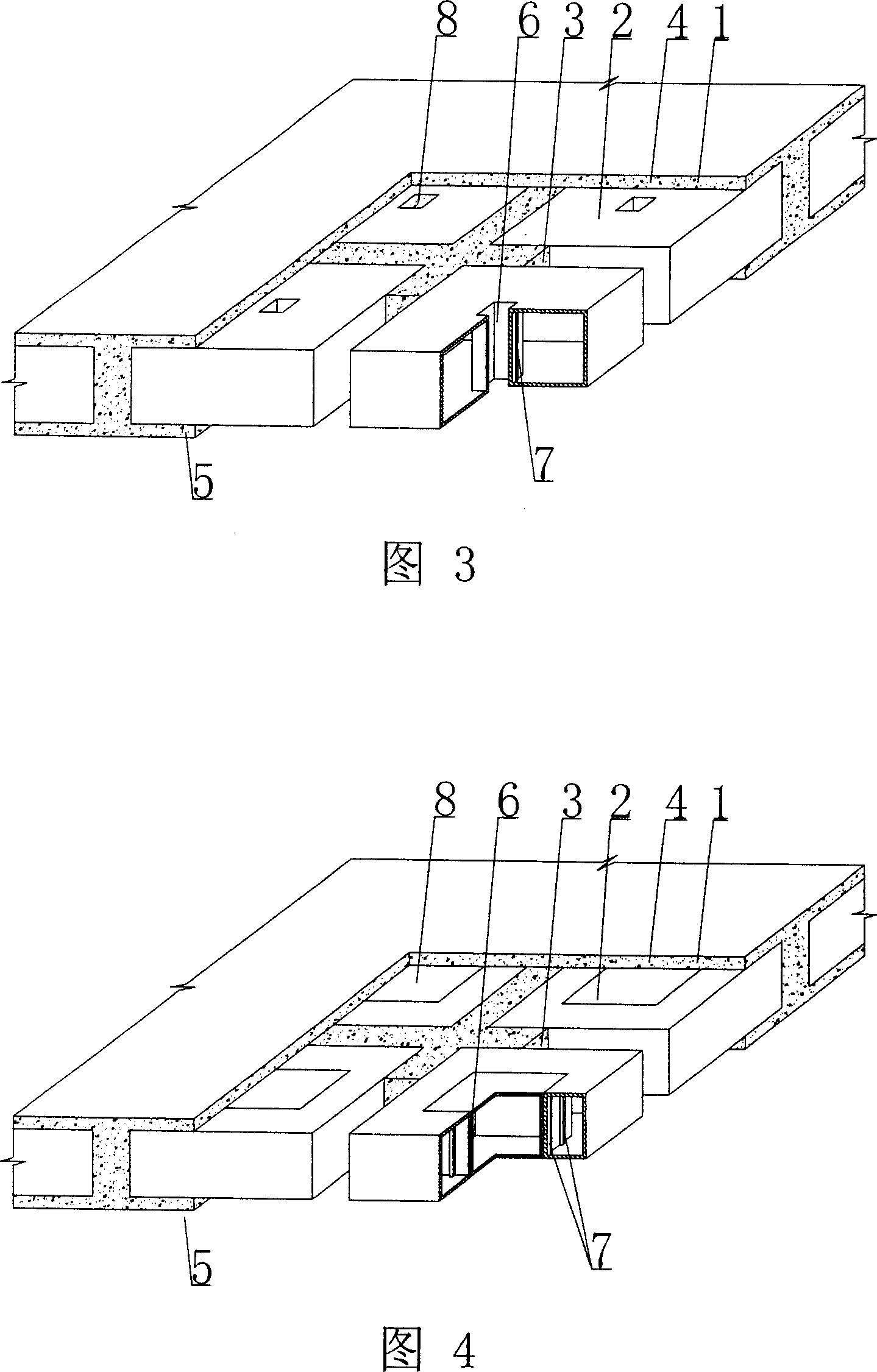

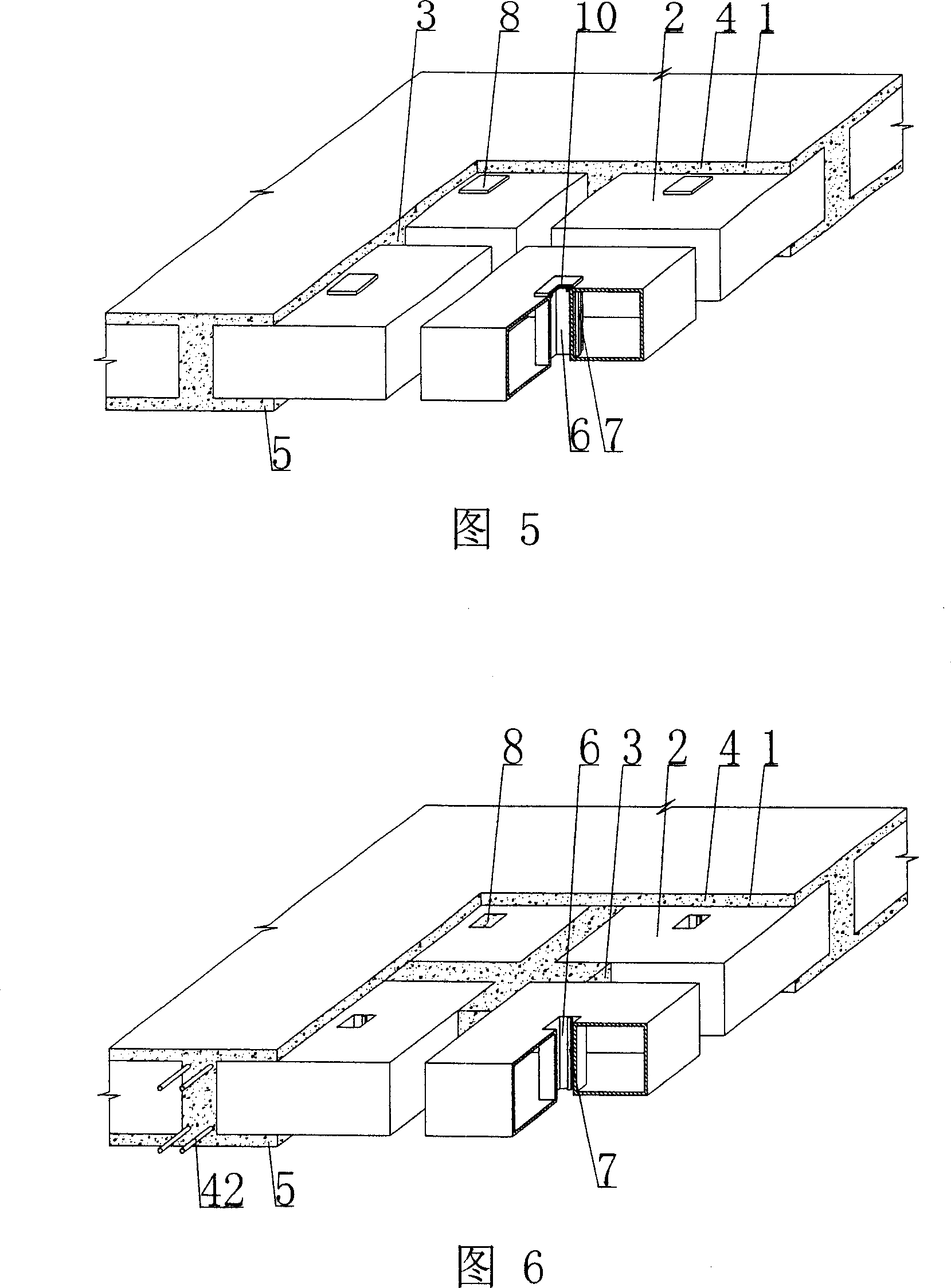

[0028] As shown in the accompanying drawings, the present invention includes a reinforced concrete 1 and a lightweight carcass 2, the lightweight carcass 2 is wrapped in the reinforced concrete 1, the lightweight carcass 2 are arranged alternately, and there are cast-in-place reinforced concrete ribs 3 between them , above which is a cast-in-place reinforced concrete upper plate 4, and under which is a cast-in-situ reinforced concrete lower plate 5, characterized in that at least one cast-in-place concrete pouring hole 6 runs through the lightweight hollow matrix 2 in the lightweight carcass 2 The upper and lower surfaces are characterized in that there is at least one vertical rod 7 on the wall of the hole, and the cast-in-place concrete is poured into the hole 6 to form a pier 8 . In each attached drawing, 1 is reinforced concrete, 2 is lightweight ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com