Wave-wheel washing machine adapted for frequency conversion technology

A pulsator washing machine and frequency conversion technology, which is applied in the field of washing machines and can solve problems affecting the efficiency of frequency conversion technology and narrow frequency conversion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

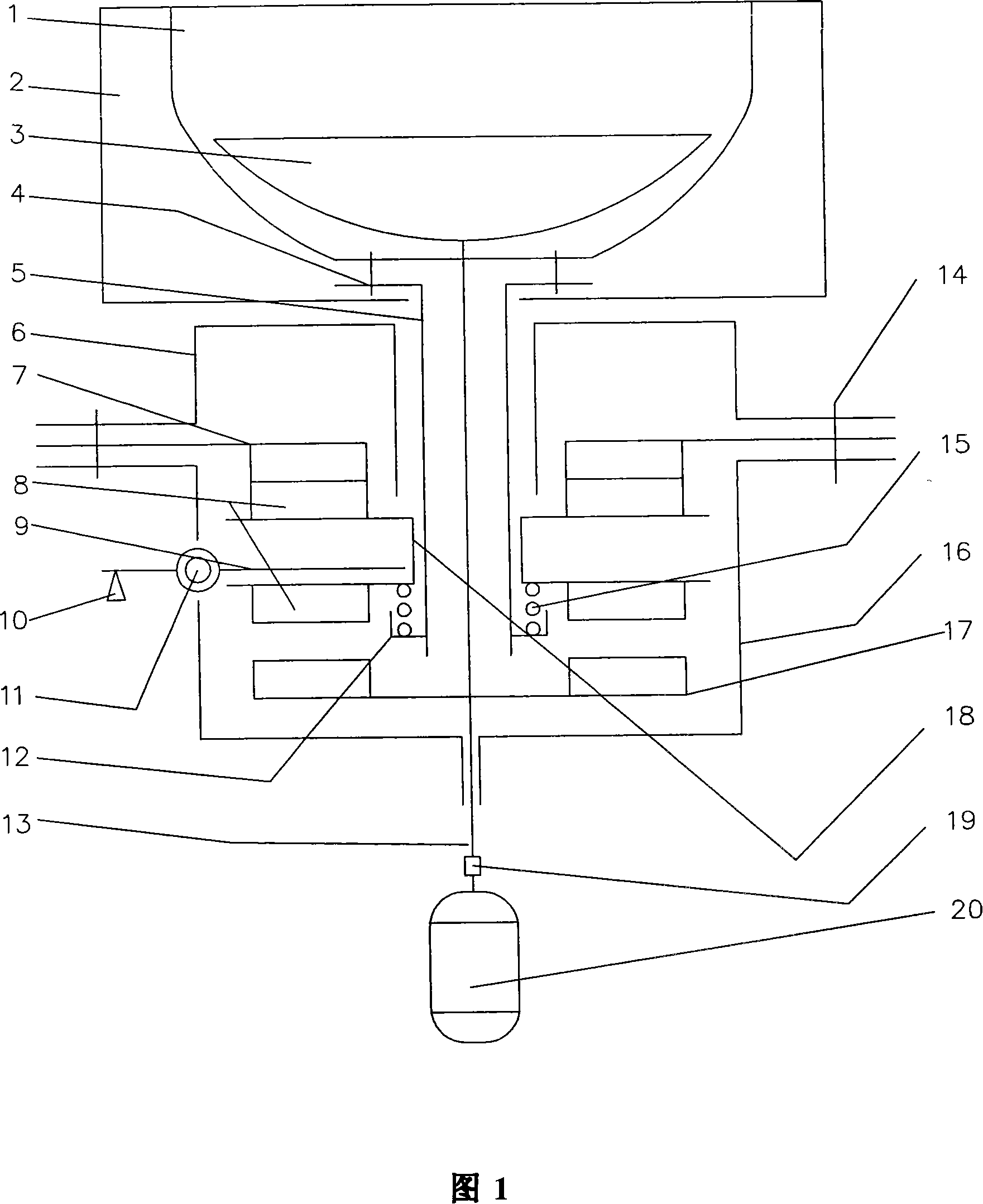

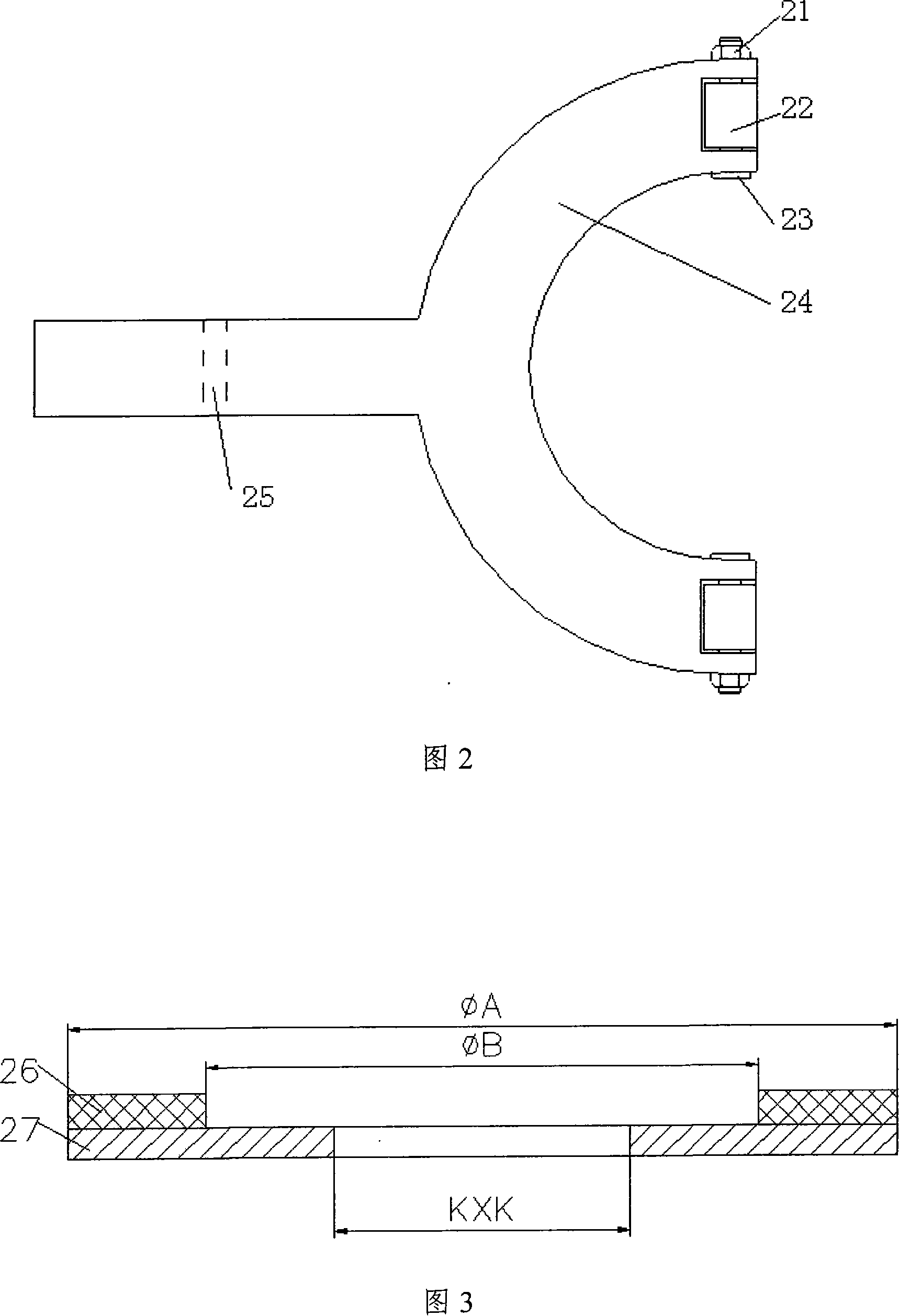

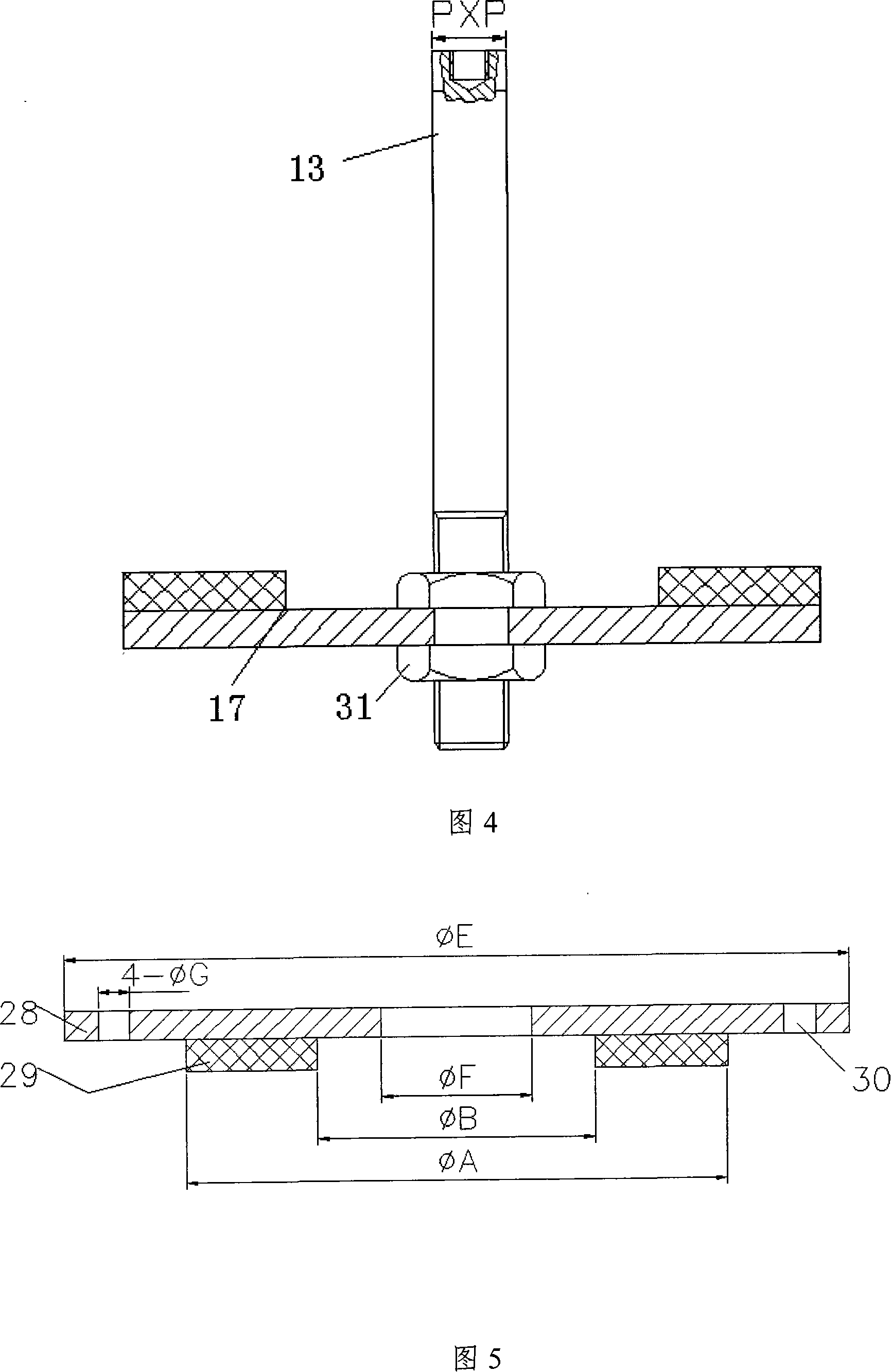

[0033] As shown in Figures 1 to 8, the present invention includes an outer tub 2, an inner tub 1 and a pulsator 3 therein, a washing shaft 13 connected to the pulsator 3 and inserted into the dehydration shaft 5, a dehydration shaft 5 connected to the inner tub 1 and The main body of the washing machine with the clutch of the drainage tractor 10 is characterized in that it also includes a variable frequency motor 20 connected to the lower end of the washing shaft 13 through a coupling 19, and the above-mentioned clutch is a synchronous clutch. The above-mentioned washing shaft 13 is an upper end And the lower part is a square cylindrical body.

[0034] The above-mentioned synchronous clutch 32 is in the upper casing 6 and the lower casing 16 which cover each other, and from the bottom of the lower casing 16 from bottom to top, it is a dehydrator fixed on the washing shaft 13 near the bottom of the lower casing 16. The friction plate assembly 17 and the sliding sleeve 18 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com