Method for manufacturing copper nano granule and copper nano granule produced thereby

A metal nanoparticle, free technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of not solving various problems, not providing the manufacture of small and uniform particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

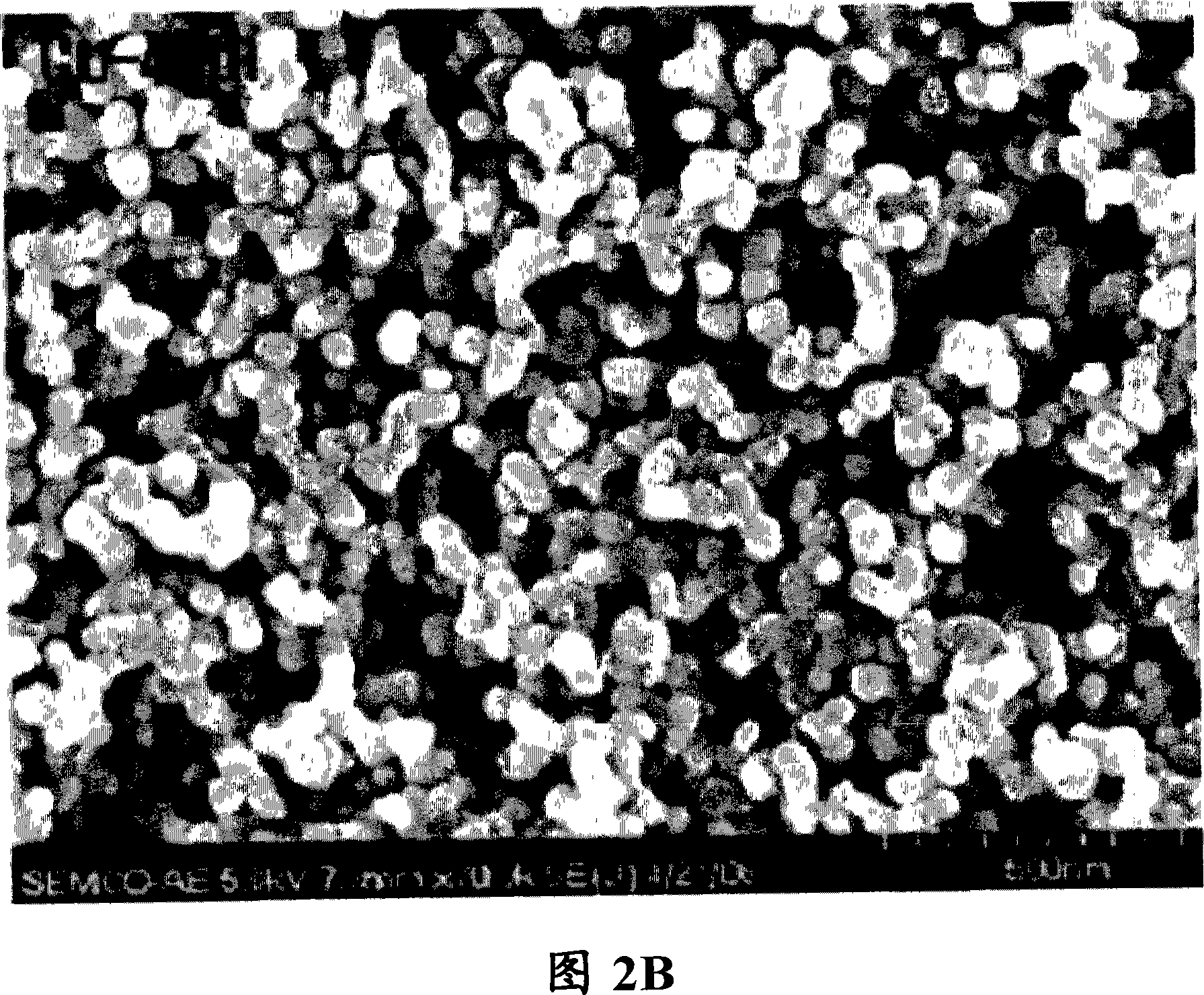

[0051] Example 1: Manufacture of Copper Nanoparticles

[0052] 0.2 mol of sodium hypophosphate and 1 mol of PVP were mixed and dissolved in 400 ml of ethylene glycol in a beaker with a stirrer to prepare a first solution, and heated to 90°C. 0.1 mol of copper sulfate was dissolved in 100 ml of ethylene glycol to prepare a second solution and heated to 90°C. The second solution was injected into the first solution all at once at 90° C., and the resulting solution was vigorously stirred with a stirrer. After the solution was turned into dark brown by the reduction reaction, cooled distilled water was added, the solution was rapidly cooled and centrifuged to obtain dark brown copper nanoparticle powder. Then, the obtained particles were washed 3 times with acetone and distilled water, and dried in a vacuum dryer at 50° C. for 3 hours to finally recover 12 g of copper nanoparticles.

Embodiment 2

[0053] Example 2: Manufacture of Copper Nanoparticles

[0054] 1.6 moles of sodium hypophosphate and 4 moles of PVP were mixed and dissolved in 900 ml of ethylene glycol in a beaker with a stirrer to prepare a first solution, and heated to 90°C. A second solution was prepared by dissolving 0.4 mol of copper sulfate in 100 ml of ethylene glycol and heated to 90°C. The second solution was injected into the first solution all at once at 90° C., and the resulting solution was vigorously stirred with a stirrer. After the solution was turned into a dark brown color by a reduction reaction, cooled distilled water was added, and the solution was rapidly cooled and centrifuged to obtain a dark brown copper nanoparticle powder. Then, the obtained particles were washed 3 times with acetone and distilled water, and dried in a vacuum dryer at 50° C. for 3 hours to finally recover 26 g of copper nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com