Applicator roll for a labeling apparatus

A technology for coating rolls and labels, applied in the field of coating rolls, can solve the problems of expensive manufacturing and running costs, and achieve the effect of reducing product and running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

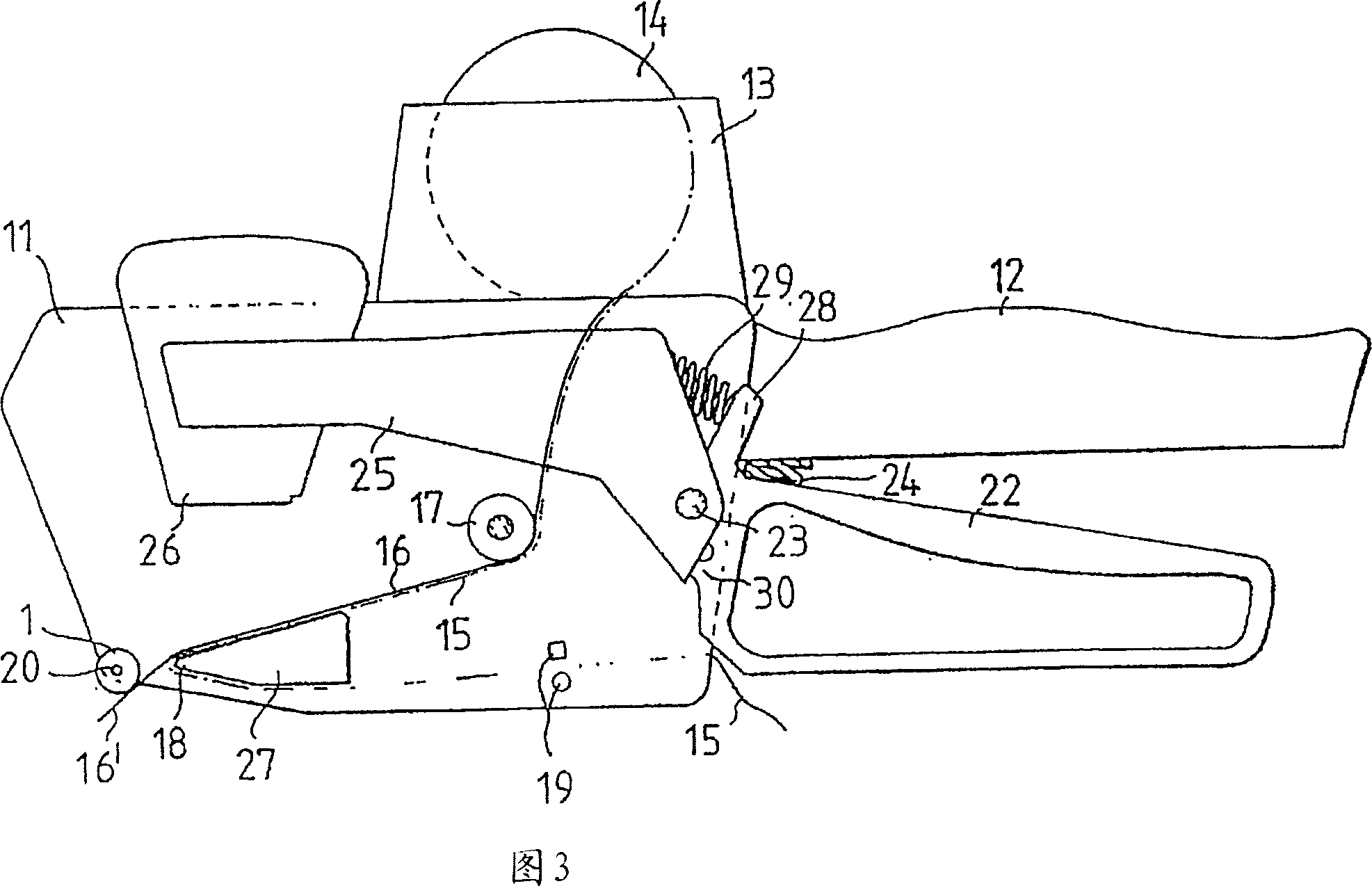

[0023] FIG. 3 shows a labeling device with a housing 11 on which a handle 12 is provided. Above the housing is a compartment 13 containing a supply roll 14 of self-adhesive labels 16 adhered to a carrier tape 15 . The carrier web 15 is first transported downwards out of the compartment 13 in the labeling device and then, after being deflected by the rollers 17, moves towards the dispensing edge 18 where it is deflected and guided through the schematically shown Feed mechanism 19 to the rear of housing 11. The applicator roll 1 is rotatably mounted on a hub 20 in front of the dispensing edge 18 inside the housing 11 . After the label 16' has been separated from the carrier belt 15 at the dispensing edge 18 at the dispensing position, the applicator roll 1 causes the label 16' to be adhered to the object by rolling the applicator roll 1 .

[0024] Attached below the handle 12 is an activation lever 22 rotatably mounted on a hub 23 . Located between the handle 12 and the trigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com