Driving plate structure and anti-leakage glue gun feeding device

A technology of feeding device and driving sheet, which is applied to spray devices, devices that apply liquid to surfaces, coatings, etc., can solve problems such as poor construction quality and waste, achieve good drip-stopping effect, optimize manufacturing process, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with the preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

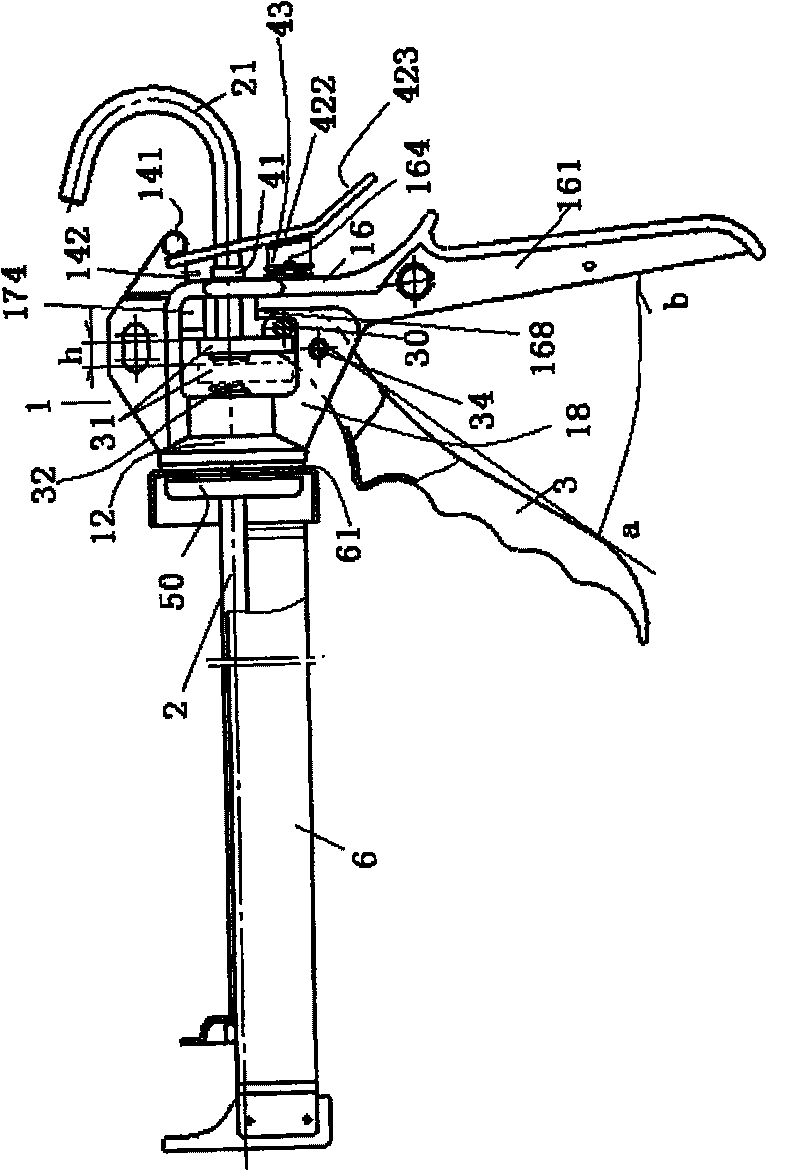

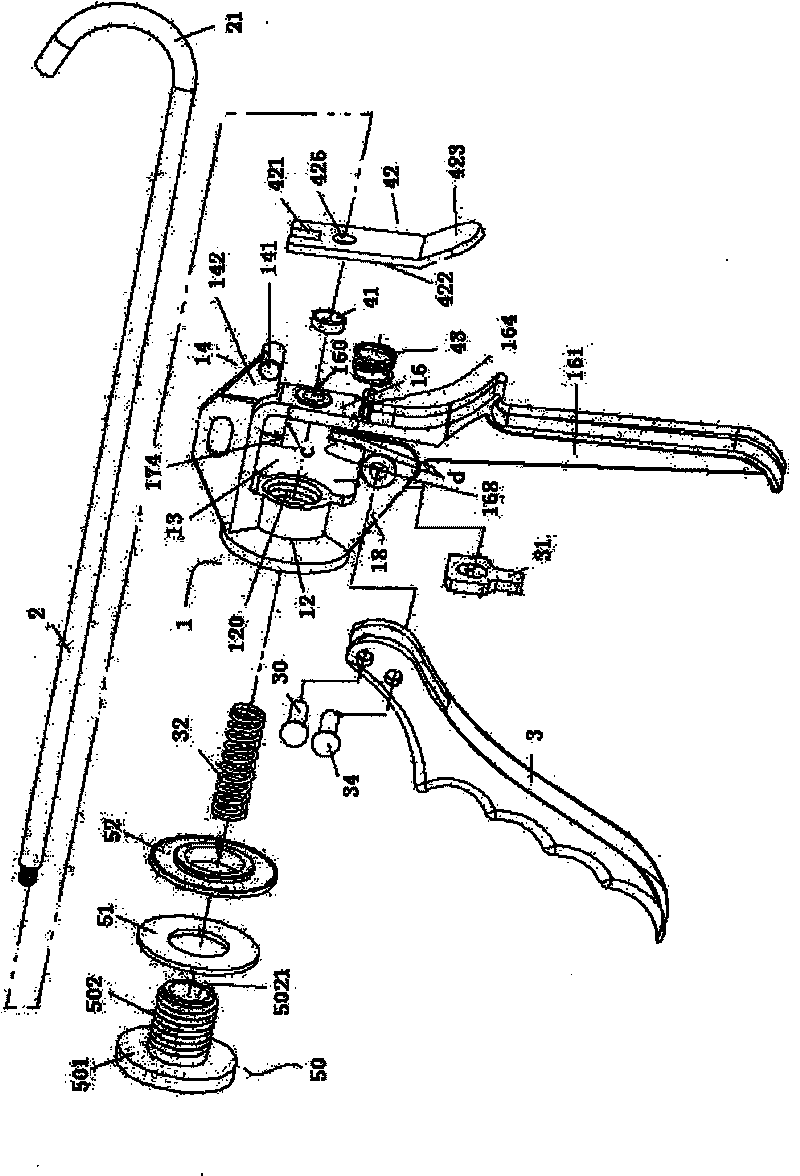

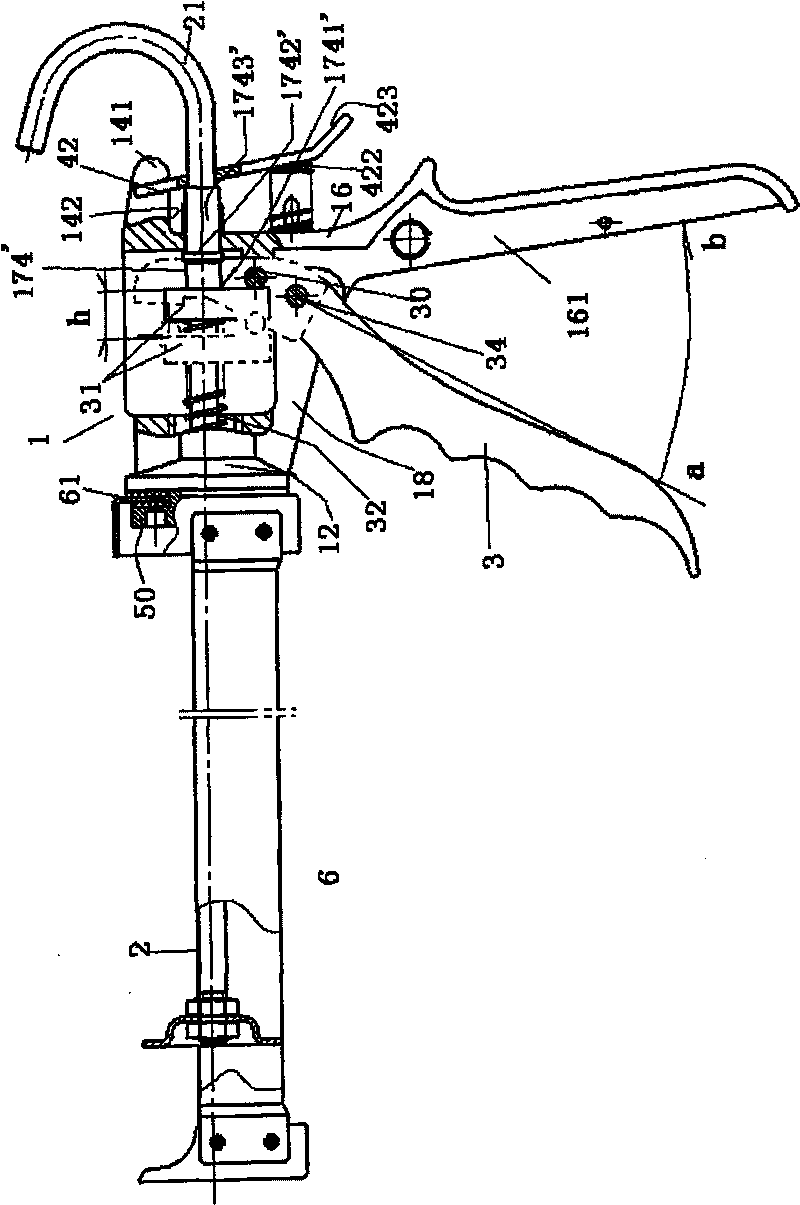

[0040]like Figure 1-9 As shown, a driving piece structure includes a driving piece body 31 that can be sleeved on a rod body, combined with a driving spring, and pushed forward by the driving rod, wherein one side of the driving piece body 31 has a The upper concave surface 3110, and the other side has a lower concave surface 3111 extending downward along the push rod penetration hole 311. The depth of the concave surface is 1 / 3 of the thickness of the driving piece. The first and second concave surfaces are set as the driving piece. When tilted by the driving force, two retreat surfaces on the front and bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com