Modified type static inhalation toxicant exposure cabinet

A poisoning cabinet and an improved technology, applied in the field of diagnostic instruments and poisoning cabinets, can solve the problems of wasting material resources, polluting the laboratory environment and the surrounding environment, and easily existing dead ends, saving electric energy, shortening test time, The effect of improving concentration uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

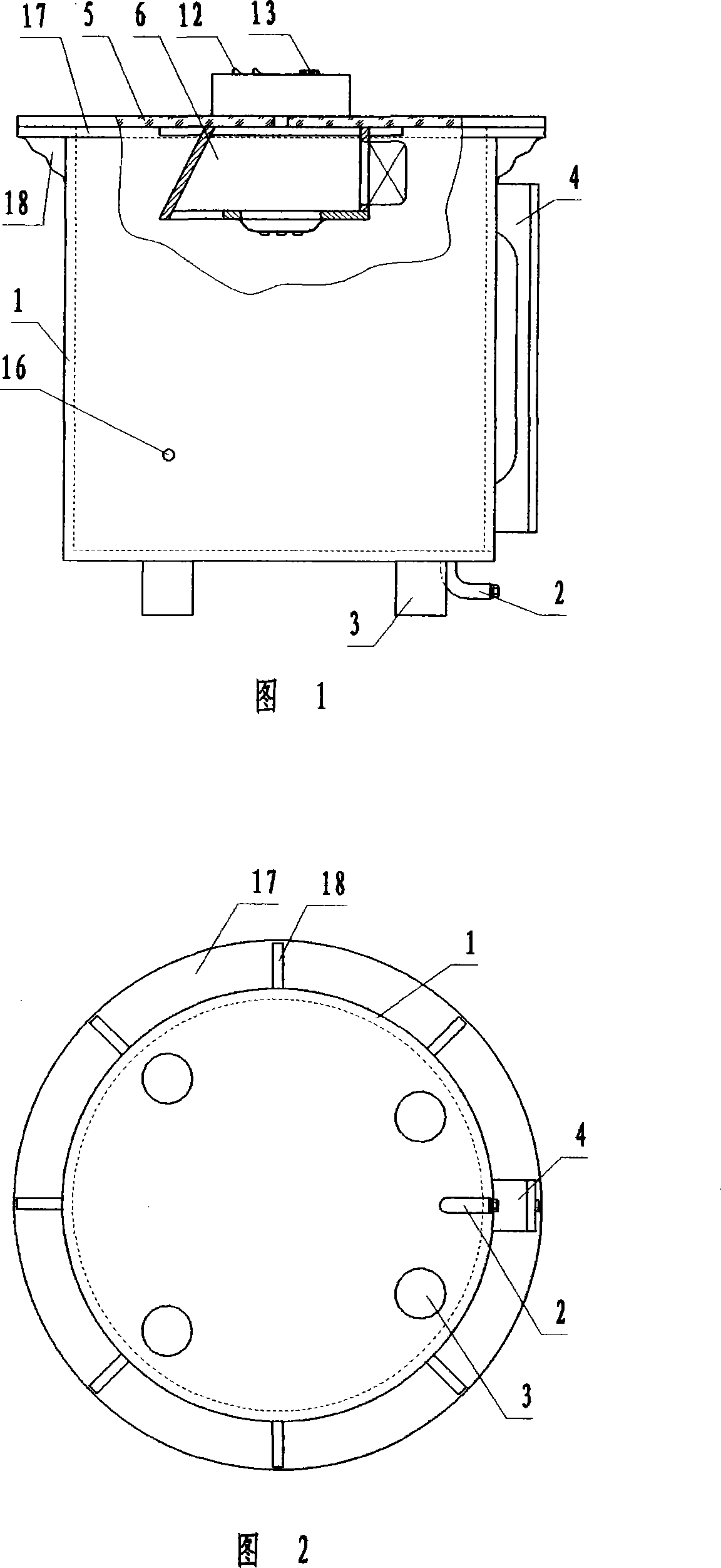

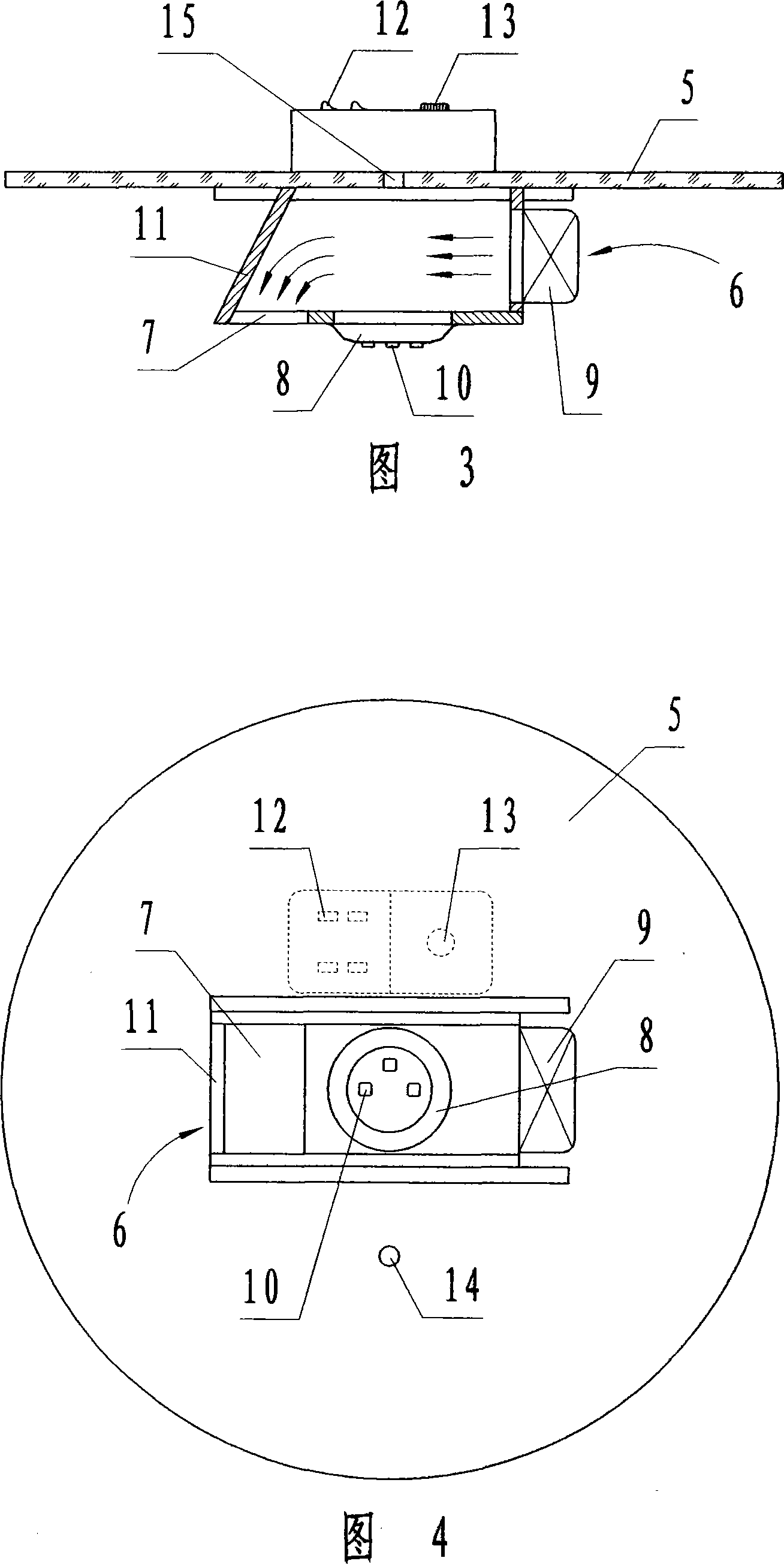

[0016] 1 and 2, the cabinet 1 is a cylindrical container made of a transparent organic glass tube, with an open upper end and a cover plate 5 on the mouth, and a closed space is formed in the cabinet 1. A sample volatilization box 6 is provided under the cover plate 5 (see Figure 3 and Figure 4). The volatilization box 6 is a tetrahedron with an evaporating dish 8 at the bottom, a fan 9 at one end, an inclined deflector 11 at the other end, and an air outlet 7 at the lower end of the deflector 11, in which the evaporating dish Three PTC heating sheets 10 are attached to the bottom of 8 as heaters. According to the vaporization point of the test chemical substance, the number of the PTC heating sheet 10 is appropriately selected, so that the test chemical substance is completely volatilized within a predetermined time. In order to obtain a wider temperature adjustment range or a finer temperature interval, the PTC heating sheet 10 can be increased to 6 or more. In order to facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com