Mask holding mechanism and film forming apparatus

A technology of holding mechanism and film forming device, which is applied in lighting devices, optomechanical equipment, ion implantation plating, etc., and can solve problems such as position deviation and inability to form patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

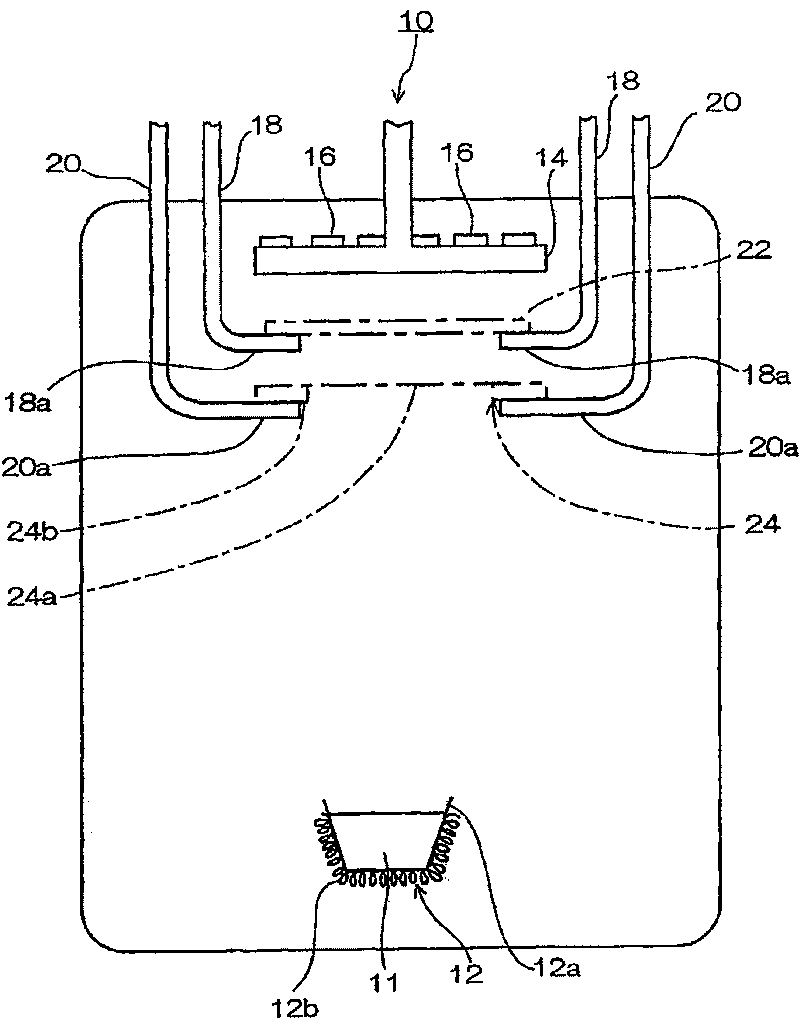

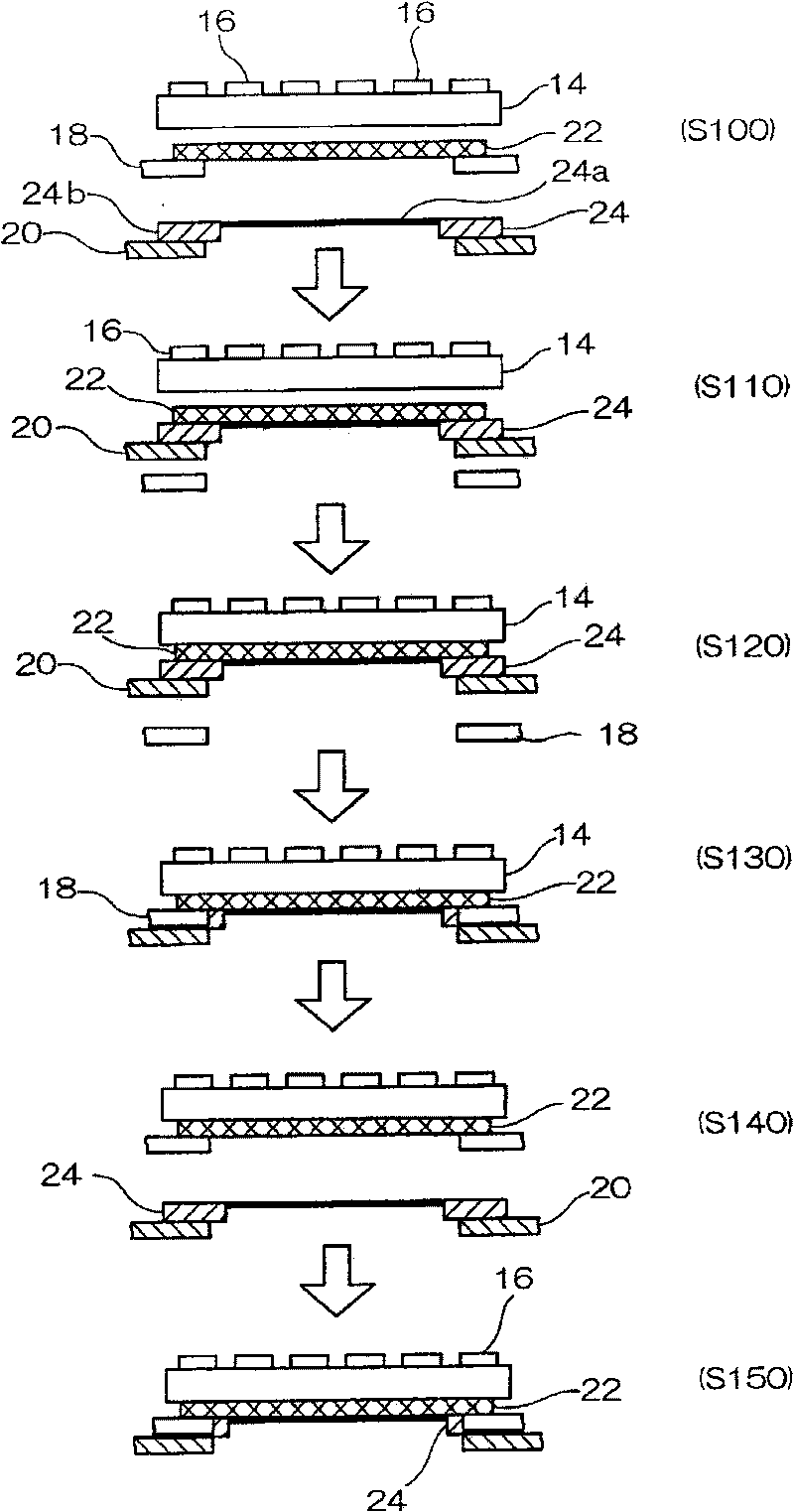

[0034] Preferred embodiments of the mask holding mechanism and film forming apparatus according to the present invention will be described below. In addition, in this embodiment, a vacuum vapor deposition device is used as a film forming device, and a mode of manufacturing an organic EL element using this vacuum vapor deposition device will be described.

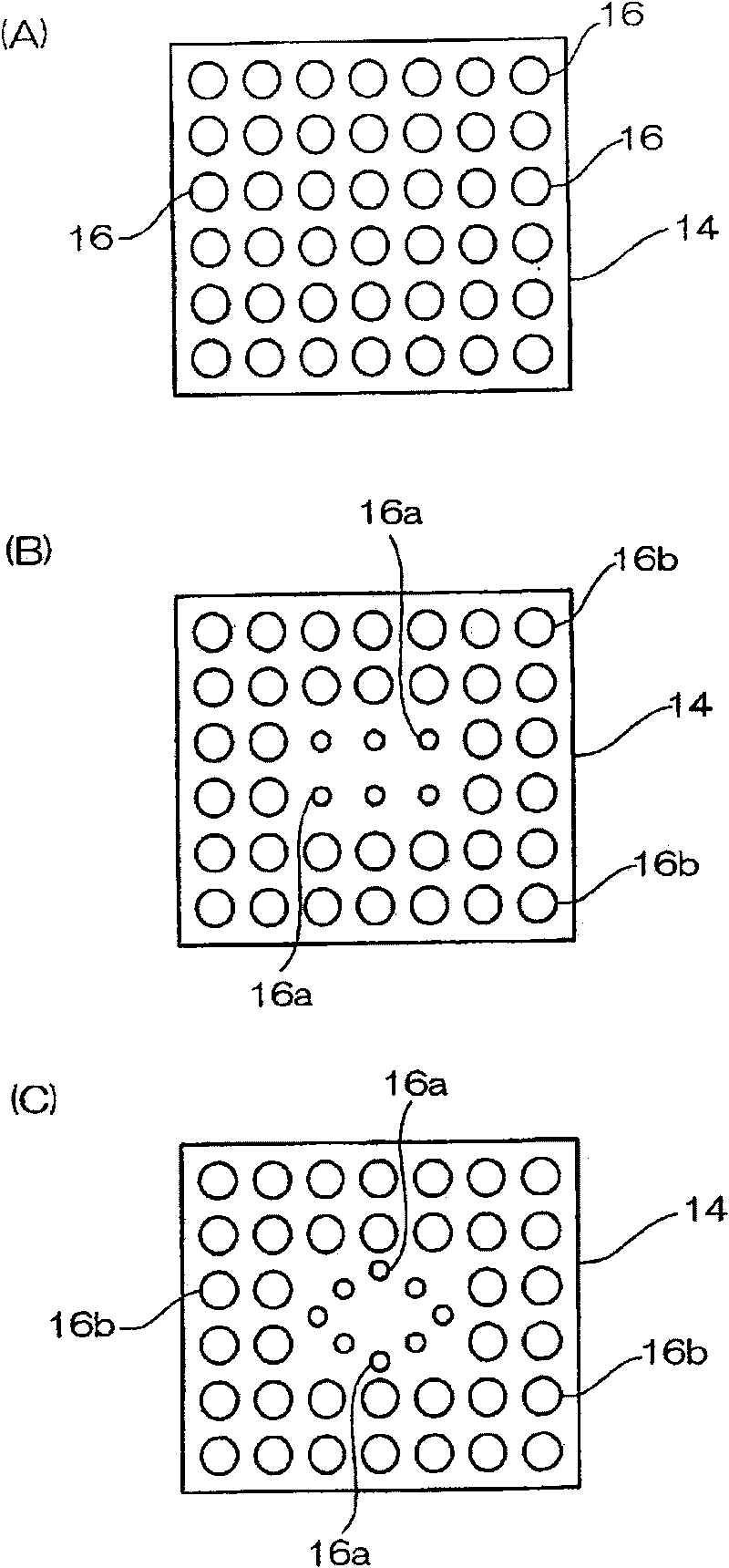

[0035] figure 1 It is an explanatory drawing of the vacuum evaporation apparatus concerning an Example. figure 2 It is a figure for explaining the arrangement|positioning of the magnet of the Example which was provided in the chuck|zipper. In these figures, the vacuum evaporation apparatus 10 is equipped with an evaporation source 12 (sublimation source) of an organic material 11 at its bottom, and is equipped with a chuck 14, a magnet 16, a substrate holder 18, and a mask holder at its upper portion. Holder 20.

[0036] The evaporation source 12 of the organic material 11 includes a crucible 12 a into which the organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com