Surface modified aluminium hydroxide fire retardant and its prepn process

An aluminum hydroxide flame retardant and surface modification technology, which is applied in the treatment of dyed low molecular organic compounds, etc., can solve the problem of not introducing the preparation method of aluminum hydroxide, not involving the preparation process of coarse and fine particle aluminum hydroxide, and adding flame retardants. It can improve the physical and mechanical properties, reduce the cost of surface treatment, and prevent the degradation of thermal oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

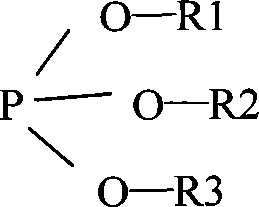

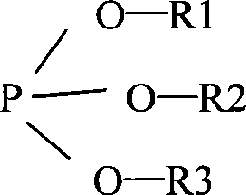

[0027]Example 1: 250 kg of industrial-grade aluminum hydroxide was first mechanically pulverized by a built-in grading turbine pulverizer, and the particle size distribution was controlled to obtain aluminum hydroxide with an average particle size of 12.5 μm, and the maximum particle size did not exceed 30 μm; The 100 kg of the powder is pulverized by a jet mill, and the particle size distribution range is 0.4-15 μm. Then 150 kg of the mechanically pulverized product and 100 kg of the jet pulverized product were placed in a coulter mixer for mixing. 3 kilograms of diisooctylphenyl phosphite, 2.7 kilograms of three (beta-chloropropyl) phosphate (TCPP), 0.5 kilograms of Si-69 silane coupling agents are added in the top spray device of coulter type mixer, add Press to 8 kg and spray. Heat the coulter mixer to 110°C, stir for 30 minutes, and discharge to obtain a white powder with good fluidity. The average particle diameter of the product was determined to be 8.9 μm.

[0028] ...

Embodiment 2

[0029] Example 2: 250 kg of industrial-grade aluminum hydroxide was first mechanically pulverized by a built-in grading turbine pulverizer, and the particle size distribution was controlled to obtain aluminum hydroxide with an average particle size of 13.2 μm, and the maximum particle size did not exceed 30 μm; The 100 kg of the powder is pulverized by a jet mill, and the particle size distribution range is 0.4-15 μm. Then 150 kg of the mechanically pulverized product and 100 kg of the jet pulverized product were placed in a coulter mixer for mixing. Add 4.5 kg of diisooctylphenyl phosphite and 0.5 kg of aminopropyltriethoxysilane coupling agent into the top spray device of the coulter mixer, pressurize to 8 kg, and spray. Heat the coulter mixer to 110°C, stir for 20 minutes, and discharge to obtain a white powder with good fluidity. The average particle diameter of the product was determined to be 9.1 μm.

[0030] The above sample was roasted and dehydrated at 500°C, and th...

Embodiment 3

[0031] Example 3: 250 kg of industrial-grade aluminum hydroxide was first mechanically pulverized by a built-in grading turbine pulverizer, and the particle size distribution was controlled to obtain aluminum hydroxide with an average particle size of 13.5 μm, and the maximum particle size did not exceed 30 μm; 200kg of the powder is crushed by a jet mill, and the particle size distribution range is 0.4-15μm. Then 50 kg of the mechanically pulverized product and 120 kg of the jet pulverized product were placed in a coulter mixer for mixing. Add 5.5 kilograms of tris (β-chloropropyl) phosphate (TCPP), 0.5 kilograms of chloropropylmethyl diethoxysilane coupling agent into the top spray device of the plow mixer, pressurize to 8 kilograms, and carry out spray. Heat the coulter mixer to 110°C, stir for 20 minutes, and discharge to obtain a white powder with good fluidity. The average particle size of the product was determined to be 5.5 μm.

[0032] The above sample was roasted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com