Chlorinated polyethylene-neoprene mixed polymer

A technology of blending polymers and chlorinated polyethylene, which is applied in the field of blended polymers of chlorinated polyethylene-chloroprene rubber, can solve problems such as the limitation of the blending ratio of chlorinated polyethylene and neoprene rubber, and achieve reduction The effect of consumption and cost reduction

Inactive Publication Date: 2010-11-24

深圳市迅特橡塑技术有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem that the blending ratio of chlorinated polyethylene and neoprene is limited in the prior art, and to provide a chlorinated polyethylene-chloroprene compound that can be blended with chlorinated polyethylene and neoprene in any proportion. Butadiene blend polymer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

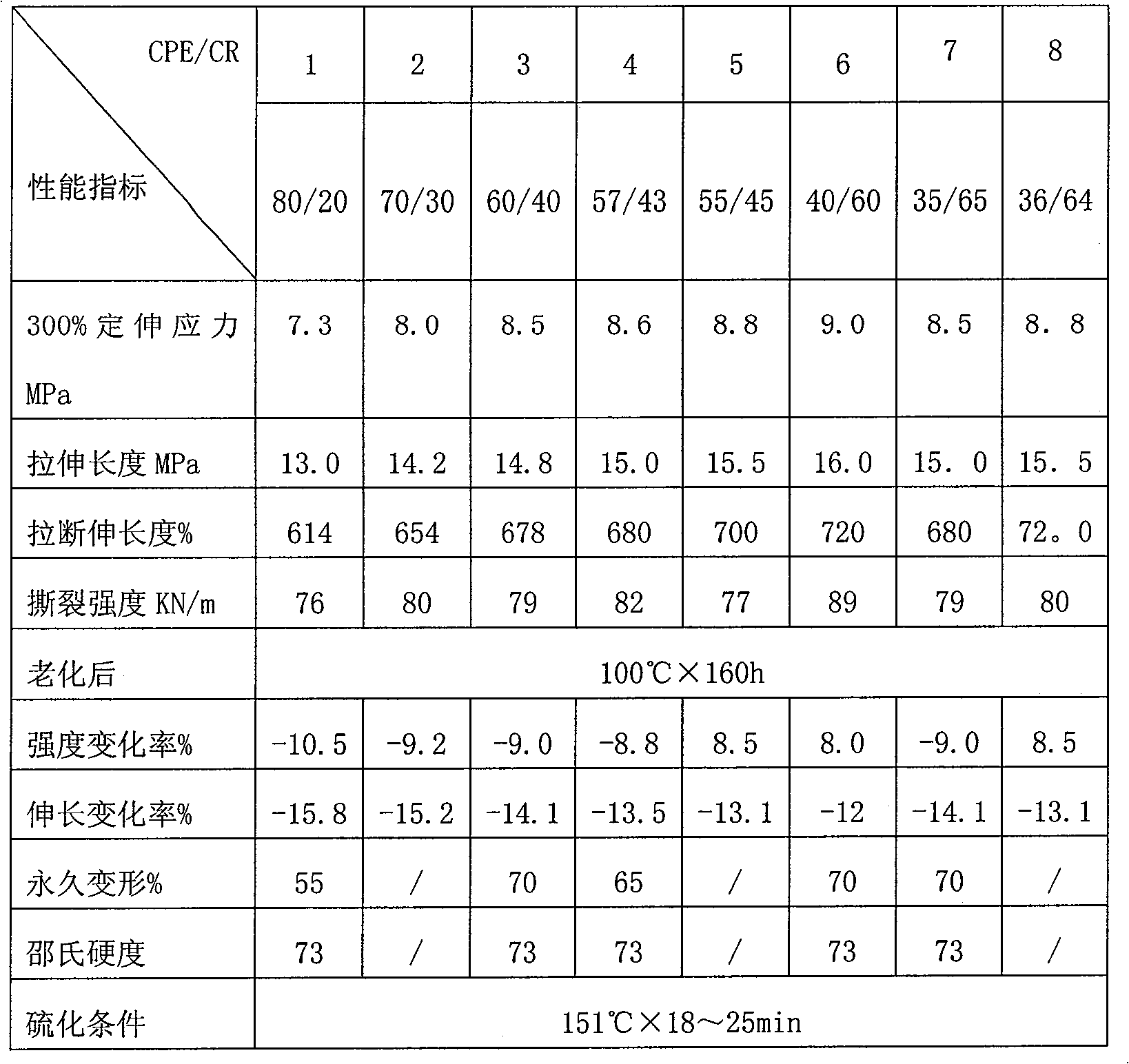

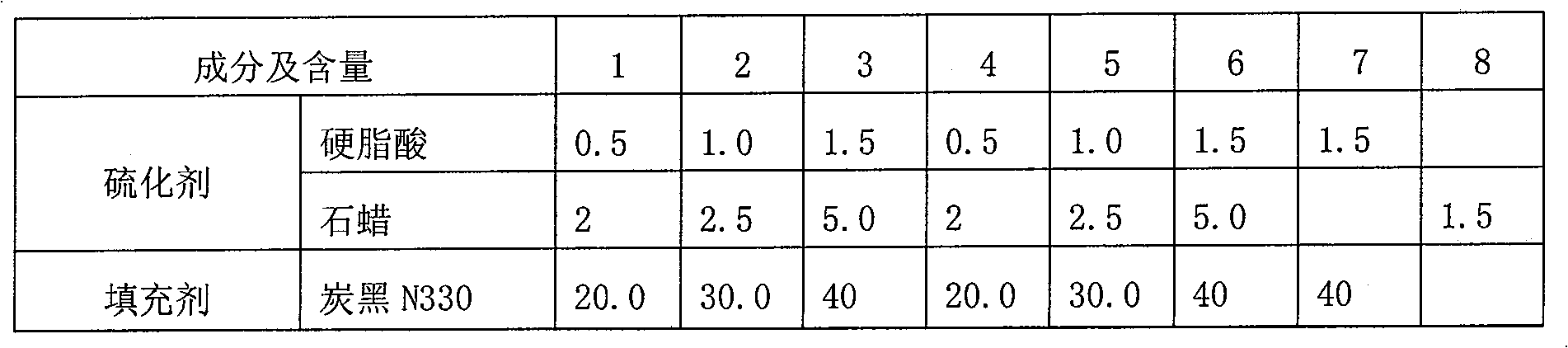

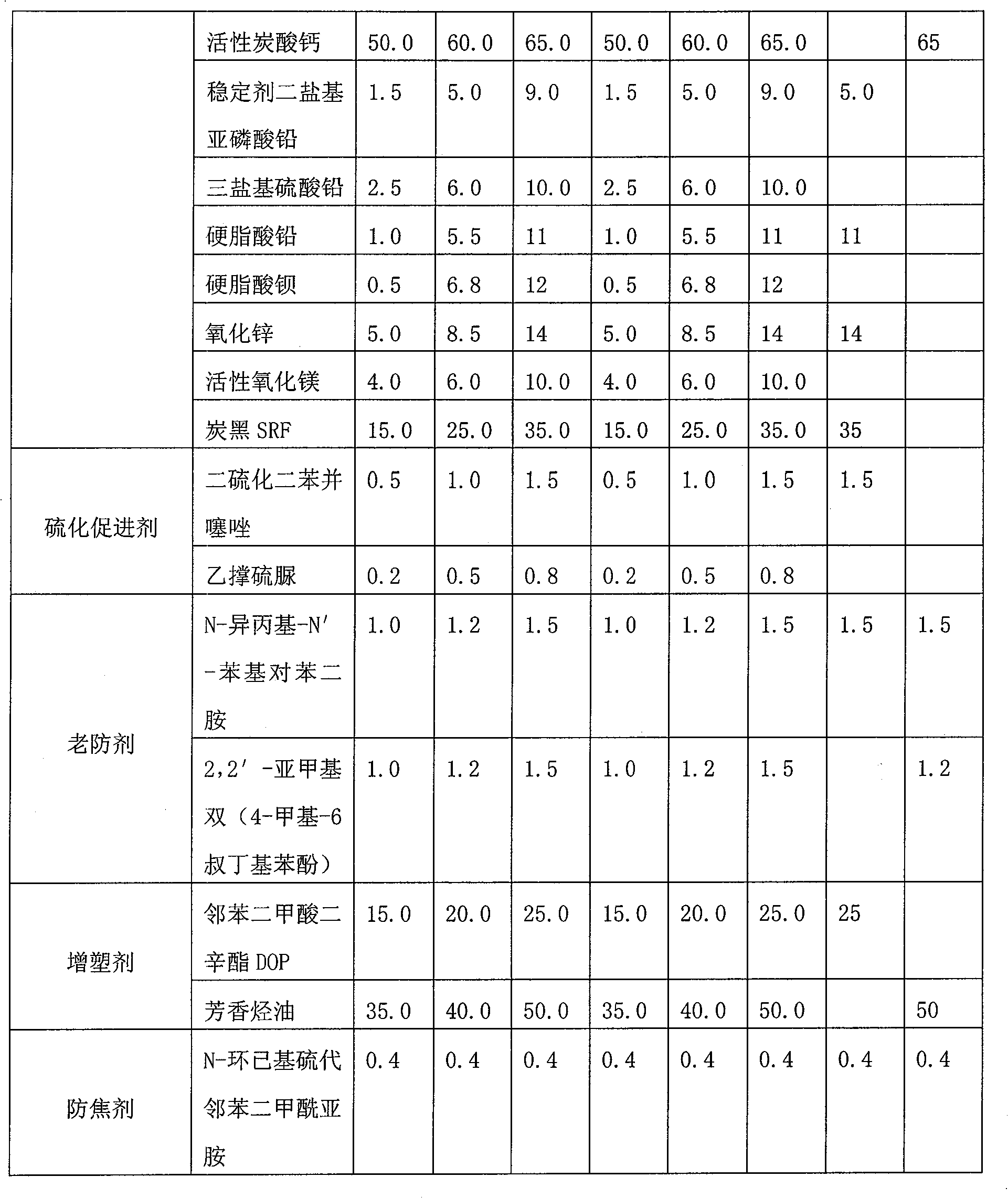

The present invention relates to one kind of polymer mixture of chlorinated polyethylene and neoprene. The polymer mixture contains chlorinated polyethylene over 40 wt%, and neoprene, as well as vulcanizing agent, stuffing, promoter, antiager, plasticizer, scorch retarder, stabilizer, etc. The polymer mixture has lowered neoprene consumption, low cost, ozone tolerance, high heat resistance, high weather resistance, high corrosion resistance, and other advantages.

Description

Chlorinated Polyethylene-Neoprene Blend Polymer technical field The invention relates to a blend polymer of chlorinated polyethylene-chloroprene rubber. Background technique Chlorinated polyethylene CPE can be dissolved with most plastics and rubbers, and has heat resistance, oil resistance, ozone resistance, chemical corrosion resistance, weather aging resistance and good electrical properties, etc. Chlorinated polyethylene CPE and neoprene CR It can be widely used in petroleum development, coal mining, aerospace, engineering machinery, automobile manufacturing, shipbuilding, nuclear power plants and other fields of high-performance supporting products. However, compared with chloroprene CR, chlorinated polyethylene CPE , CPE has superior performance and low price. How to reduce the amount of neoprene, ensure the excellent performance of the product, reduce costs as much as possible, and make the product more market-competitive is a problem to be solved in the prior art; ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L23/28C08K5/47C08L11/00C08K3/04C08K3/22C08K5/09

Inventor 巴君山

Owner 深圳市迅特橡塑技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com