Electric brake and energy recovery system for brushless DC motor

A technology of electronic braking and energy recovery, applied in the direction of stopping devices, etc., can solve the problems of interference control mechanism and low energy recovery ratio, and achieve the effect of reliable braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

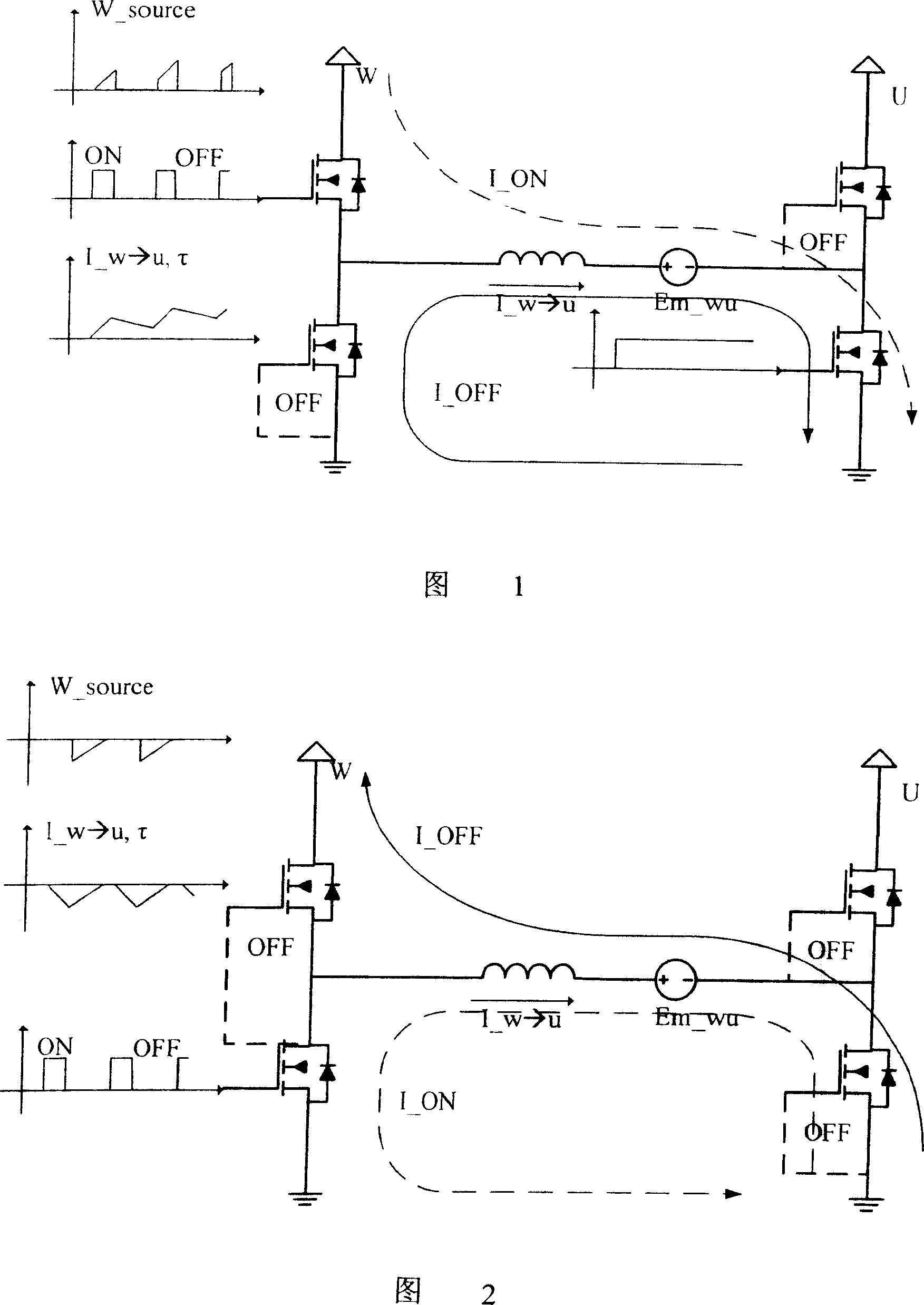

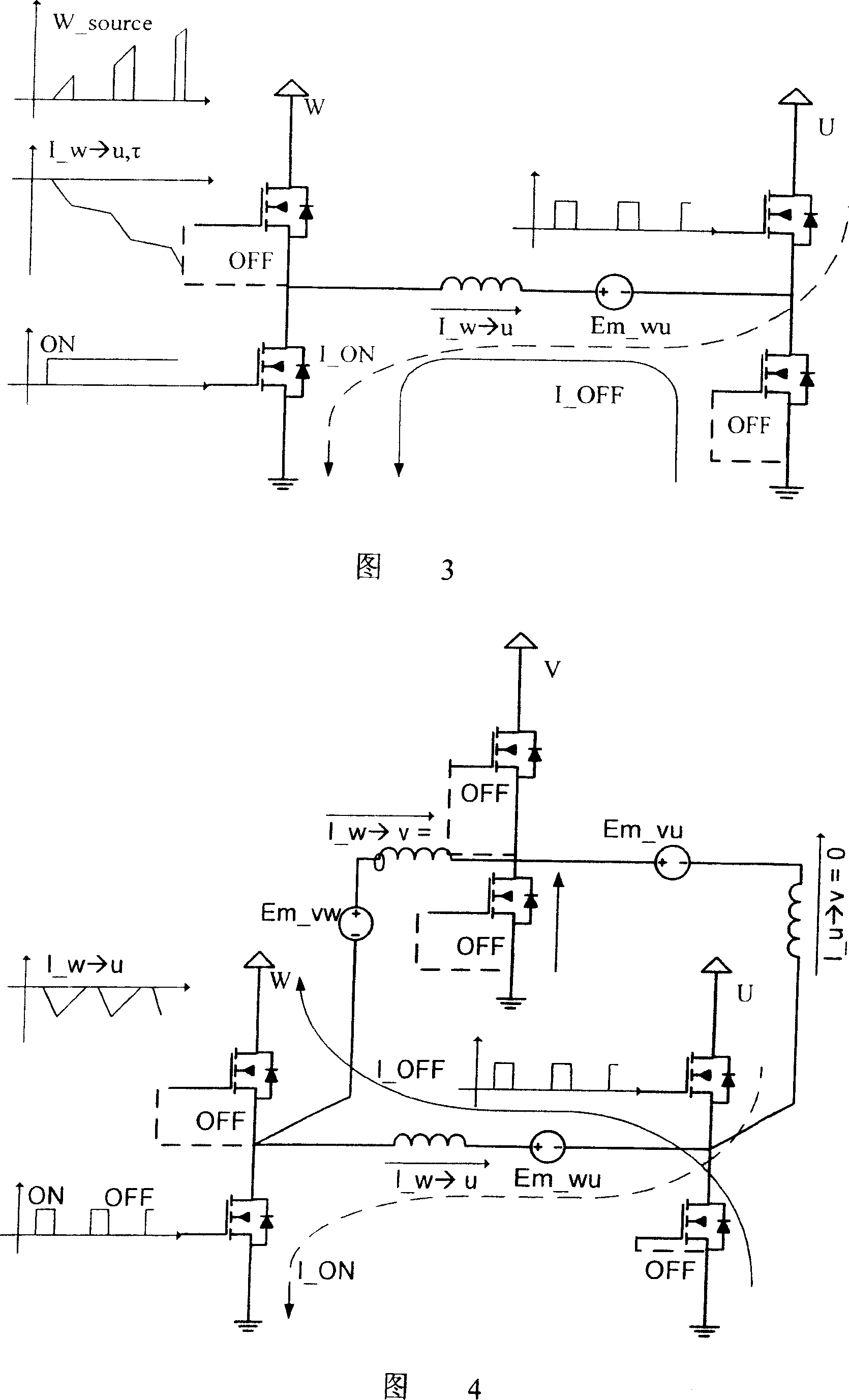

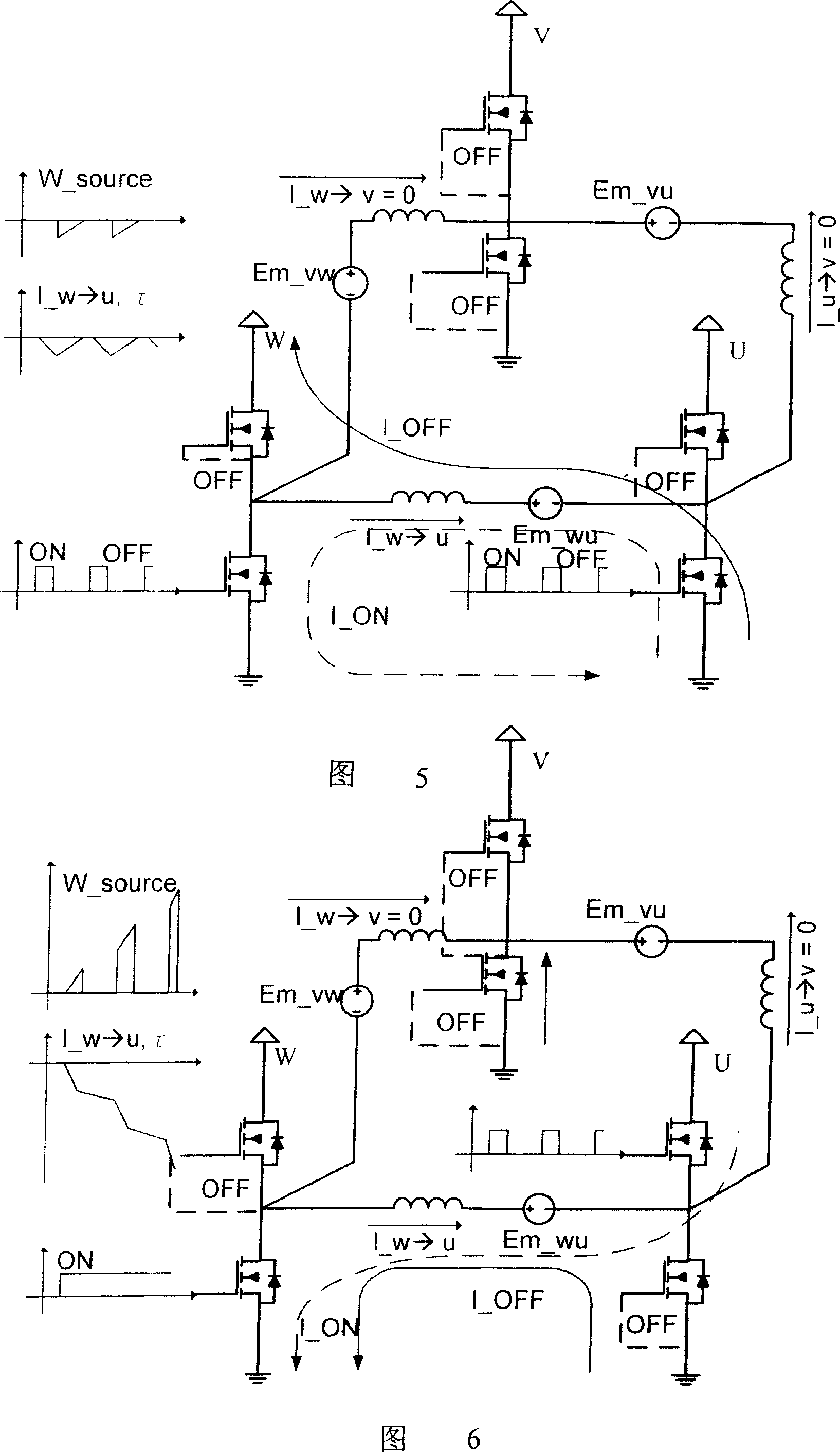

[0022] The electronic braking and energy recovery system used in the brushless DC motor of the present invention can be realized through simple electronic gate voltage signal conversion without changing the hardware structure of the original motor controller and motor. Practically control the function of the reverse torque brake, without the interference of multi-phase coils, and recover the kinetic energy of the motor to the maximum proportion. Please refer to Figure 7. The current direction of the motor coil under control is marked in the circuit. When the electronic brake system is activated, the controller applies the voltage on the motor coil in reverse mode. At this time, the current relationship on the motor coil is (volt Second Law, Voltage-Time Law: V_ motor ×Δt_ ON =L_ motor ×Δi_ motor )

[0023] (ε motor +V source )×Δt ON =L motor ×Δi motor (1), the only difference is that at this time the MOSFET on the left lower arm is not kept on (On Status), but is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com